Workers at the Hanford Site’s Waste Treatment and Immobilization Plant have completed testing key safety systems inside the plant’s Low-Activity Waste Facility, moving the facility toward commissioning to support the Direct-Feed Low-Activity Waste Program to immobilize tank waste in glass.

A contractor is using an innovative system at the Hanford Site to cut into a waste-filled underground tank, showcasing new technology that improves efficiency and reduces worker and environmental risks.

The Oak Ridge Office of Environmental Management and contractor UCOR took another step forward in the construction of the Mercury Treatment Facility at the Y-12 National Security Complex.

The U.S. Department of Energy Office of Environmental Management is deploying drones for the first time to perform internal inspections of radioactive liquid waste tanks at the Savannah River Site.

Contractor teams recently collaborated to transfer 4,000 gallons of wastewater between two Hanford Site facilities.

Workers at the Hanford Site recently finished filling the last large concrete basin at the K Reactor Area with cement-like grout. The basin stored reactor fuel rods from the plutonium production mission.

A One Hanford contractor partnership has developed a new process to ensure radioactive and chemical tank waste is ready for pretreatment quickly and efficiently at the Hanford Site.

A student who worked on a capstone project for the U.S. Department of Energy Office of Environmental Management’s liquid waste contractor at the Savannah River Site (SRS) heard a calling to join the nuclear industry.

Crews at the Hanford Site’s Waste Treatment and Immobilization Plant are maintaining a large-scale thermal catalytic oxidizer to prepare for operations.

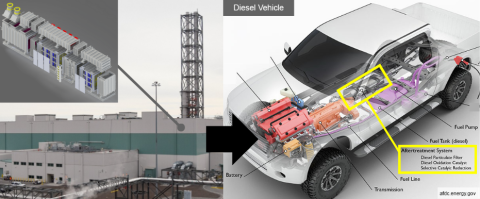

Hanford Site workers are installing equipment to demonstrate how an alternative treatment technology could safely accelerate cleanup of radioactive tank waste.