New and returning members of the Hanford Advisory Board (HAB) recently toured several Hanford Site facilities, including a full-size mock-up of a single-shell waste-storage tank at the site’s Cold Test Facility.

Idaho Cleanup Project crews have achieved a significant priority set by the U.S. Department of Energy Office of Environmental Management by treating 100,000 cumulative gallons of radioactive sodium-bearing tank waste at the Integrated Waste Treatment Unit this year.

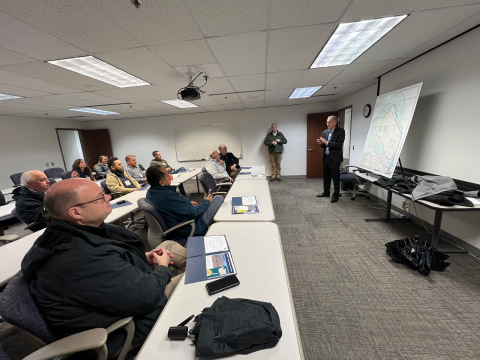

Dozens of people from federal and state agencies and Hanford Site contractors recently gathered to celebrate completing the last of 77 environmental permits needed to start treating waste from Hanford’s large underground tanks.

Cleanup progress at the Hanford Site generates interest around the world. That’s why the Hanford Field Office and tank operations contractor Washington River Protection Solutions recently hosted a site tour for representatives from Washington state’s agriculture industry.

The U.S. Department of Energy Office of Environmental Management has had one of its unused stainless steel canisters become a learning tool at Aiken Technical College in South Carolina.

The Savannah River Site has achieved a milestone with more than 10 million gallons of liquid radioactive waste processed through the Salt Waste Processing Facility.

A record amount of radioactivity has been reduced over the last two years in waste tanks at the U.S. Department of Energy Office of Environmental Management's Savannah River Site.

About 2,000 gallons of radioactive and chemical tank waste is one step closer to disposal as part of a treatment technology demonstration at the Hanford Site.

The U.S. Department of Energy Office of Environmental Management received concurrence this month from the South Carolina Department of Environmental Services and U.S. Environmental Protection Agency that the Savannah River Site has successfully removed waste from Tank 9 and may now proceed to the next step in the closure process for that tank.

Workers recently completed an 18-month project of replacing 11 hot cell windows at the 222-S Laboratory on the Hanford Site.