The U.S. Department of Energy (DOE) Office of Environmental Management (EM) has received a shipment of replacement centrifugal contactors for the Salt Waste Processing Facility (SWPF) at Savannah River Site (SRS), which should increase production at the facility by reducing the amount of downtime for maintenance.

U.S. Department of Energy Office of Environmental Management team members at the Savannah River Site (SRS) recently replaced equipment essential to operations in the H Canyon chemical separations facility following more than six months of research, troubleshooting and coordination.

Workers are upgrading and strengthening the framework of the Hanford Site’s local area network to continue supporting the cleanup mission for years to come.

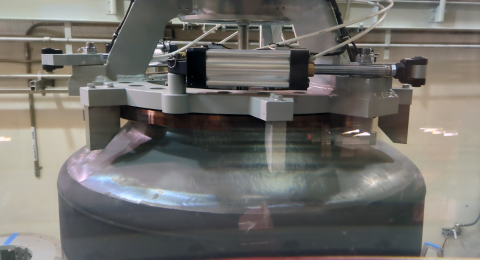

Crews at the Hanford Site’s Waste Treatment and Immobilization Plant are using containers of test glass to hone their skills on operating equipment used to seal lids on containers that will be filled with immobilized waste.

A team of federal contractor and national laboratory engineers and scientists from the U.S. Department of Energy (DOE) Office of Environmental Management (EM) has been nationally distinguished as “Heroes of Chemistry” for making the world better through their effort, ingenuity, creativity and perseverance.

The Hanford Site continues to reduce environmental risk as crews start retrieval operations of radioactive and chemical waste from a third set of underground storage tanks.

The Hanford Site’s 222-S Laboratory, operated by contractor Navarro-ATL, is upgrading the specialized equipment personnel use to safely handle and analyze samples to support cleanup operations across the site.

Control room personnel monitor systems at the Hanford Site’s Waste Treatment and Immobilization Plant after recently adding the first batch of “tuning feed” to one of the plant’s large melters.

Hanford workers recently used a robotic arm to help remove an old 34-foot pump from a large underground tank, called AP-102, that stores radiological and chemical waste.

Workers have finished removing radioactive waste from the 21st large underground storage tank as part of the massive cleanup of the Hanford Site in southeast Washington state.