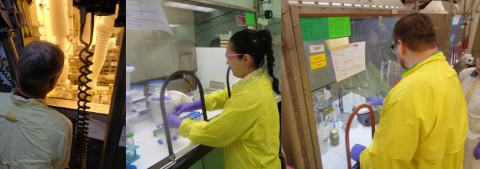

Technicians at the Hanford Site’s 222-S Laboratory, operated by U.S. Department of Energy Office of Environmental Management contractor Navarro-ATL, are processing the second batch of radioactive tank waste samples in support of the Direct-Feed Low-Activity Waste (DFLAW) Program.

For more than a decade, the U.S. Department of Energy Office of Environmental Management’s Office of River Protection has collaborated with national and international laboratories, universities and glass industry experts to plan and prepare for 24/7 operations at the Waste Treatment and Immobilization Plant (WTP) at the Hanford Site.

Workers recently unloaded a shipment of more than 10,000 gallons of sodium hydroxide delivered to the Hanford Site’s Waste Treatment and Immobilization Plant (WTP). The liquid sodium hydroxide will be the first chemical fed into the plant’s melters to simulate Hanford tank waste.

The U.S. Department of Energy (DOE) Office of Environmental Management (EM) and contractor Washington River Protection Solutions (WRPS) recently demonstrated a potential new approach to refurbish double-shell tanks (DSTs) at the Hanford Site.

Crews at the Hanford Site’s Waste Treatment and Immobilization Plant (WTP) have poured the first test glass from a second melter into a stainless steel container in the plant’s Low-Activity Waste (LAW) Facility.

Laboratory testing at the Hanford Site confirms that over 200,000 gallons of treated radioactive waste is ready to be vitrified, or immobilized in glass.

The U.S. Department of Energy Office of Environmental Management received concurrence from the South Carolina Department of Health and Environmental Control and U.S. Environmental Protection Agency on May 23 that the Savannah River Site has successfully removed waste from Tank 10 and may now proceed to the next step in the closure process for that tank.

The U.S. Department of Energy Office of Environmental Management’s (EM) Office of River Protection and contractor Bechtel National Inc. recently created a plan for completing the High-Level Waste (HLW) Facility at the Hanford Site’s Waste Treatment and Immobilization Plant.

Workers with U.S. Department of Energy (DOE) Office of Environmental Management contractor Washington River Protection Solutions (WRPS) recently demonstrated two improved methods they intend to use for removing an old hydraulic pump from a large, underground tank storing radioactive and chemical waste at the Hanford Site.

Crews at the Hanford Site’s Waste Treatment and Immobilization Plant (WTP) recently started the permanent joule heating system in the second of two melters in the plant’s Low-Activity Waste Facility.