Internships at the Hanford Site are giving local students a chance to gain valuable skills and start their careers while helping support the cleanup of one of the nation’s most complex environmental projects. January 13, 2026

Hanford Site crews recently finished digging a new disposal area at the Environmental Restoration Disposal Facility, the site’s engineered landfill. December 23, 2025

Crews used cranes and lifts to install heavy steel beams nearly 60 feet above the Waste Treatment and Immobilization Plant’s High-Level Waste Facility on the Hanford Site. December 23, 2025

2025 Accomplishments

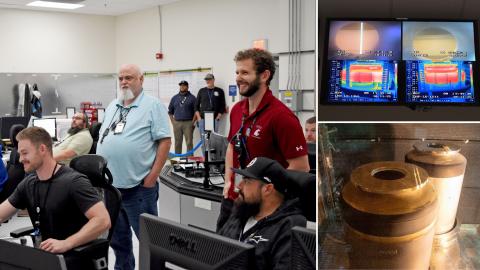

Crews at the Hanford Site have introduced an advanced metal coating technology to help extend the life of underground tanks that hold radioactive waste. December 16, 2025

Keeping the Hanford Site community safe is a 24/7 operation for the Hanford Patrol and Hanford Fire Department. The two teams strengthen coordination by practicing how they would respond together during an emergency, including an active shooter situation. December 16, 2025

Assistant Secretary Tim Walsh welcomed U.S. Secretary of Energy Chris Wright to the Hanford Site.

The Hanford Site’s Waste Treatment and Immobilization Plant has reached another major commissioning milestone, producing more than 20 stainless steel containers of immobilized low-activity waste. December 9, 2025

Crews at the Hanford Site have safely moved more than 130 large waste containers from two outdoor storage areas at the Central Waste Complex, completing a significant risk-reduction project a year ahead of schedule. December 9, 2025

Workers at the Hanford Site have made room for more than 1 million gallons of waste storage, supporting cleanup efforts to transfer waste from older underground tanks to newer, double-shell tanks. November 25, 2025