Crews recently installed a new treatment tower at the Hanford Site, giving a major boost to a groundwater cleanup effort that processes billions of gallons of contaminated water each year.

The 222-S Laboratory plays an important role in analyzing radioactive tank waste at the Hanford Site — so when crews needed to shut down the facility’s power for a full week to complete infrastructure upgrades, timing and precision were everything.

Hanford’s Test Bed Initiative could pave the way for future tank waste treatment options

A key facility supporting the Hanford Site’s tank waste cleanup mission is back in service following a series of repairs, upgrades and training sessions.

Swapping out an air filter at home is a simple task that most people can complete in minutes. But replacing dozens of massive, high-efficiency filters in a 70-year-old plutonium processing plant? That's a challenge.

The Hanford Site’s Waste Treatment and Immobilization Plant is taking computer-based training to the next level by creating virtual walkthroughs of plant facilities.

Hanford firefighters are training in emergency response with teams at the Waste Treatment and Immobilization Plant as the site gets ready to start treating radioactive waste from large, underground tanks.

Sometimes major cleanup projects require some, well, post-cleanup cleanup.

he Hanford Site’s Waste Treatment and Immobilization Plant recently received more than 3,500 gallons of sodium hydroxide, commonly known as lye.

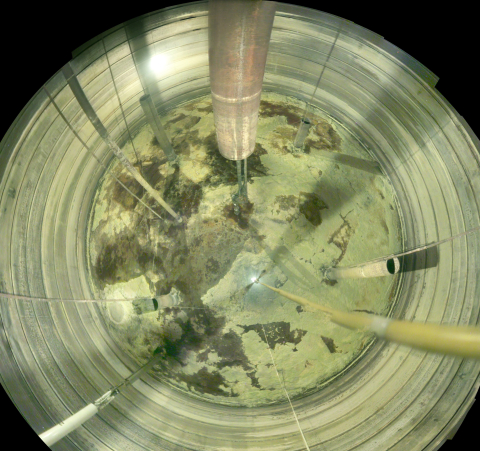

The Hanford Field Office and its tank operations contractor recently began retrieving radioactive and chemical waste from another large, underground storage tank at the Hanford Site.