The Office of Environmental Management Hanford Field Office awarded Hanford Site Waste Treatment and Immobilization Plant contractor Bechtel National Inc. approximately $14.2 million, or about 95% of the available fee for work performed last year.

In the spirit of giving, a U.S. Department of Energy Office of Environmental Management Hanford Field Office contractor is putting surplus personal protective equipment to good use on the Hanford Site.

Workers at the Hanford Site’s Waste Treatment and Immobilization Plant are sporting a new accessory for the first time: radiological dosimeters

Crews at the Hanford Site recently tackled a unique challenge with moving a 70-ton crane needing repairs.

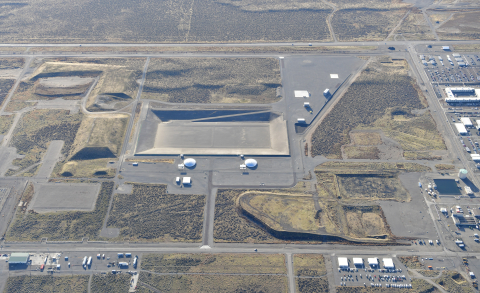

It won’t be long before the Integrated Disposal Facility is ready for its critical role in the mission to treat tank waste through the Direct-Feed Low-Activity Waste (DFLAW) Program at the Hanford Site.

The Hanford Field Office and tank operations contractor Washington River Protection Solutions are working with a local business to create a full-scale mock-up for the next phase of liquid radioactive waste pretreatment.

About 40 students from local rural high schools visited the Hanford Site’s Volpentest HAMMER Federal Training Center to learn about the U.S. Department of Energy Office of Environmental Management mission and career opportunities in STEM fields at the site.

The U.S. Department of Energy Office of Environmental Management successfully completed the majority of its 2024 priorities, advancing critical cleanup work with the support of state, tribal and local partners.

The Hanford Site is a step closer to immobilizing radioactive liquid tank waste in glass for safe disposal.

Crews with U.S. Department of Energy Office of Environmental Management contractor Central Plateau Cleanup Company are making progress cleaning up the “backyard” at the Central Waste Complex on the Hanford Site.