Built through a DOE-supported public-private effort, this technology has already uncovered a record-setting rare earth deposit and is shaping a new model for domestic resource discovery.

Office of Technology Commercialization

June 3, 2025Critical minerals are essential to modern life, supporting everything from smartphones and medical equipment to advanced defense systems. The United States depends on other countries for these materials, which makes us vulnerable to market changes and international issues.

In 2018, as the need for rare earth elements (REEs) and other critical minerals increased, the Office of Fossil Energy and Carbon Management (FECM) tasked the National Energy Technology Laboratory (NETL) with finding more domestic sources. NETL's expertise in geology and energy materials, along with new research suggesting untapped potential in the U.S., led the team to explore areas not traditionally considered sources of these minerals.

Dr. Kelly Rose and NETL’s Geoscience Artificial Intelligence & Assessment (GAIA) research group believed that America’s sedimentary basins might hold more than previously realized. These areas, rich in clay, coal, shale, and sandstone, hadn’t traditionally been viewed as sources of critical minerals.

“There were peer-reviewed, site-specific studies that indicated the potential for what we've come to call ‘unconventional’ feedstocks for critical minerals—those from nontraditional sources such as coal and clay, something the U.S. is actually rich in," explains Dr. Rose.

Accelerating Discovery Through Innovation

The goal was not just to find new sources of critical minerals. The real challenge was figuring out how to locate them quickly, assess the form and type of each deposit, and transfer that knowledge to the people responsible for evaluating sites in the field. That information could then be used to inform decisions about how best to extract and process those resources.

Through this collaborative project, the NETL-led team created an advanced method to rapidly analyze geological data. When coupled with their AI-powered prospectivity forecasting model, it enables users to more efficiently and systematically assess potential sites for critical minerals in unconventional sources.

To further improve the process, the team developed a standard way to identify and measure critical elements in geological materials, both in the lab and in the field. Combining this method with AI-informed analysis significantly improves the accuracy of resource estimates and is already being used in research and commercial projects.

The speed at which this first-of-its-kind analysis was developed is particularly noteworthy. Historically, it has taken decades to establish the commercial viability of resources like uranium, oil, natural gas, and groundwater. In contrast, the development of unconventional critical minerals and byproduct sources is developing much faster—driven by the integration of AI, NETL’s focused research, and a strong collaboration with industry partners. This work has contributed to that momentum, identifying a major domestic resource in less than eight years and establishing new models and methods that others can use to replicate the effort.

From Lab to the Real World

Creating a new research tool is only half the battle; getting it into the hands of those who can use it is the other.

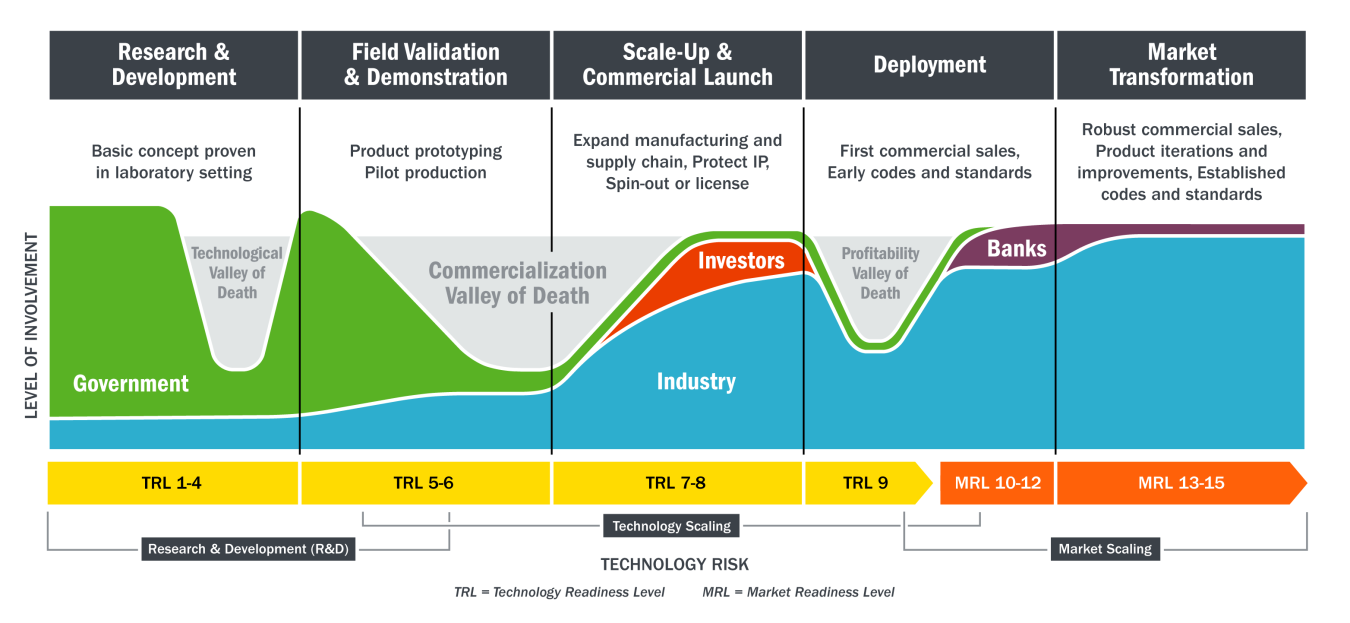

The team has proven that the system works in real-world applications. However, the next big challenge is bridging the "commercial valley of death," where many promising technologies struggle to reach the market without support for scaling up, licensing, or private-sector adoption.

That's where the DOE’s Technology Commercialization Fund (TCF) comes in. Managed by the Office of Technology Commercialization, the fund helps bridge the gap between research and the commercial market. With TCF support, NETL researchers are partnering with Ramaco Resources and Weir International to mature and demonstrate the technology — a critical step in enabling a successful hand-off to private enterprise.

"The commercial sector has different goals and stakeholders," Dr. Rose explains. "The TCF is essential because it helps translate the research into something that the commercial sector can use."

A Big Opportunity

While the team is not making specific economic predictions, the early signs are promising. At the Brook Mine in northeastern Wyoming—owned by project partner Ramaco—an assessment using NETL’s AI model identified a significant deposit. This deposit is now considered the largest known source of magnetic rare earth elements in the United States derived from an unconventional source. The Wall Street Journal highlighted this discovery, emphasizing its potential for practical application and commercial use.

“This partnership has been pivotal to starting the creation of a new American supply chain for critical minerals, reducing our dependency on foreign sources,” said Randall Atkins, Chairman and CEO of Ramaco Resources. “The Brook Mine will be the first new REE mine in the United States in over seventy years, and NETL’s research staff and technology has been fundamental to its development. Everyone on this project is laser-focused on the imperative of ensuring the U.S. has the materials it requires for its economic prosperity and national defense.”

This technology can speed up the discovery and development of domestic unconventional critical mineral feedstocks, sedimentary deposits hosted by underclays or coal, and byproducts such as mine tailings, across the United States. By using data to predict where resources are located, companies can improve their exploration and focus on the most promising areas.

"The U.S. may have more unconventional sources of rare earth elements and other critical minerals than traditional ones, but we need more data to confirm this," notes Gabe Creason, another member of NETL’s GAIA research team. "The TCF supported project will help commercial users find and understand these resources more efficiently. It also supports other DOE FECM efforts to unlock the potential of these new resource types."

The Brook Mine discovery and the growing commercial momentum around unconventional sources are happening at a pivotal policy moment.

In March, President Trump signed an Executive Order aimed at expanding domestic mineral production and streamlining the permitting process for mining on federal lands. It prioritizes critical materials, including rare earths.

Then in April, another Executive Order turned the spotlight on coal. It called for considering metallurgical coal as a potential critical mineral under federal mineral strategy and directed DOE to support technologies that extract useful materials from coal and coal byproducts.

These directives align with and accelerate DOE’s efforts to commercialize coal ash recovery and expand domestic mineral production. The NETL-led effort—backed by DOE programs and industry partners—demonstrates how once-overlooked materials and regions, like those in the Powder River Basin, can play a central role in rebuilding U.S. supply chains and reducing reliance on foreign sources. These communities have long powered the nation, and with new tools, policy direction, and a focus on domestic resources, they are ready to do so again.

Looking Ahead

This technology has the potential to transform how the United States develops critical minerals, turning overlooked areas into new hubs of economic growth and energy production.

Currently, the United States relies entirely on imports for several critical minerals, including many rare earth elements. Reducing this dependence is essential for securing supply chains for advanced manufacturing, defense, energy, and medical technologies. This project is a promising step toward building that capacity at home.

Dr. Rose is optimistic about the technology's commercial future: "I am hopeful that it will be adopted commercially because our partners are so invested and are working with us to meet the energy sector’s needs."

This project demonstrates what can happen when public investment, scientific talent, and private industry pull in the same direction. With the right tools and support, innovation doesn’t have to take decades. Sometimes the future is right under your feet. You just need a better way to find it.