The U.S. Department of Energy Office of Environmental Management and its liquid waste contractor at Savannah River Site have implemented an agile, innovative toolset that expands near-term planning capabilities enabling optimized facility integration that improves the overall schedule for treating radioactive waste. February 17, 2026

Office of Environmental Management

February 17, 2026The Integrated Processing Projection Tool automates the ability for Savannah River Mission Completion managers to graphically see how short-term production changes can affect other processes and facilities. The tool is seen as a new way to help move the Savannah River Site Liquid Waste Program to completion.

AIKEN, S.C. — The U.S. Department of Energy (DOE) Office of Environmental Management and its liquid waste contractor at Savannah River Site (SRS) have implemented an agile, innovative toolset that expands near-term planning capabilities enabling optimized facility integration that improves the overall schedule for treating radioactive waste.

Savannah River Mission Completion (SRMC) is responsible for treating and disposing of the millions of gallons of waste remaining in underground tanks at SRS, as well as closing the tanks. One of the capabilities SRMC uses in mission planning is computer modeling tools developed by DBD Inc., an SRMC subcontractor.

The first model identifies process or facility improvements most likely to accelerate the SRS liquid waste mission. Computer models create digital representations, or simulations, of real-world processes. The outputs from the computer models are used to create tables, charts and schedules published in the SRS Liquid Waste System Plan and inform annual budget requests for cleanup activities.

The original model continues to be used for long-term system planning four years or more into the future. A new model, known as the Integrated Processing Projection Tool (IPPT), simulates the effects of processing changes down to a much shorter period and produces a graphical depiction of integrated facility processing, automating a process previously performed manually by knowledgeable employees. The IPPT focuses on the daily operation of facilities, helping to develop coordinated processing strategies for the short term.

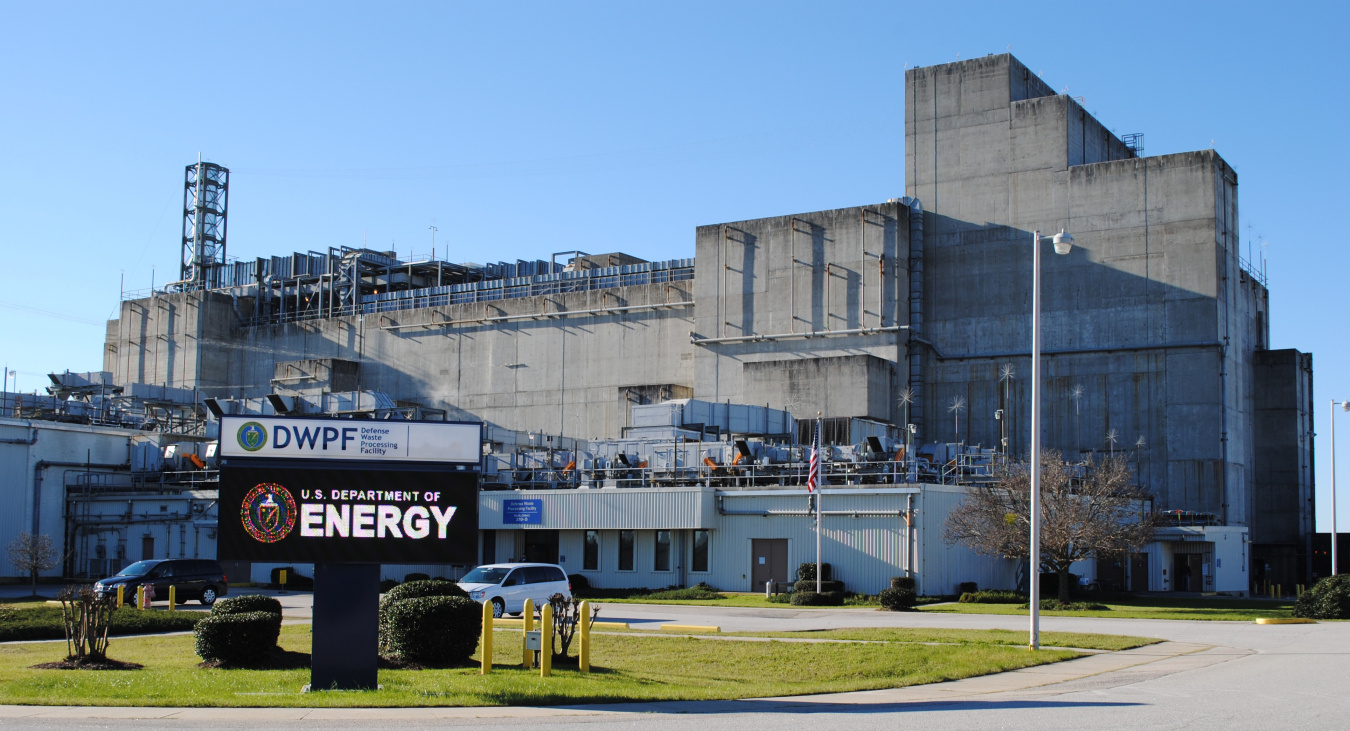

Savannah River Mission Completion’s Integrated Processing Projection Tool provides a significant improvement to system planning. The tool is used to estimate how long a Defense Waste Processing Facility outage can last without impacting salt waste production or mission completion goals. This software automation delivers the graphic in seconds and gives users a greater sense of an unexpected outage’s impact.

DOE-Savannah River acting Assistant Manager for Waste Disposition Tony Robinson expects the new short-term forecasting model to improve facilities planning for more optimized results.

“This update to the modeling software is an example of how we are leveraging the power of innovative technologies to further accelerate our cleanup efforts to address legacy waste,” Robinson said.

The IPPT delivers quick, clear and organized output for routine scenarios, an analysis of outages in one or more facilities, and provides for “what-if” scenarios that could occur, according to SRMC Senior Vice President for Optimization and Integration Steve Howell.

“This new capability helps SRMC obtain the best results possible and execute even more effectively,” Howell said. “We can now see all our short-term options and scenarios more quickly and clearly. This tool provides SRMC management with the information needed to make swift and strategic processing decisions in the near term.”

When emergent outages occur, a short turnaround of the modeling graphic can help managers align priorities, while considering other pending maintenance activities. For example, when specific data is input, the system model can estimate how long a Defense Waste Processing Facility outage can last without impacting salt waste production or mission completion goals. This software automation delivers the graphic in seconds and gives users a greater sense of an unexpected outage’s impact.

−Contributor: Jim Beasley

To receive the latest news and updates about the Office of Environmental Management, submit your e-mail address.