Read more about solar manufacturing:

What is Solar Manufacturing?

Solar manufacturing refers to the fabrication and assembly of materials across the solar value chain. Solar photovoltaic (PV) modules include many subcomponents like wafers, cells, encapsulant, glass, backsheets, junction boxes, connectors, and frames. In addition to modules, there are many manufactured products required for solar energy systems, including inverters, wiring, combiner boxes, and racking and tracking structures—and that’s just for PV. Concentrating solar-thermal power (CSP) systems, for example, require the manufacturing of heliostats, receivers, and thermal storage systems. Learn more about how PV manufacturing works.

Solar Manufacturing in the United States

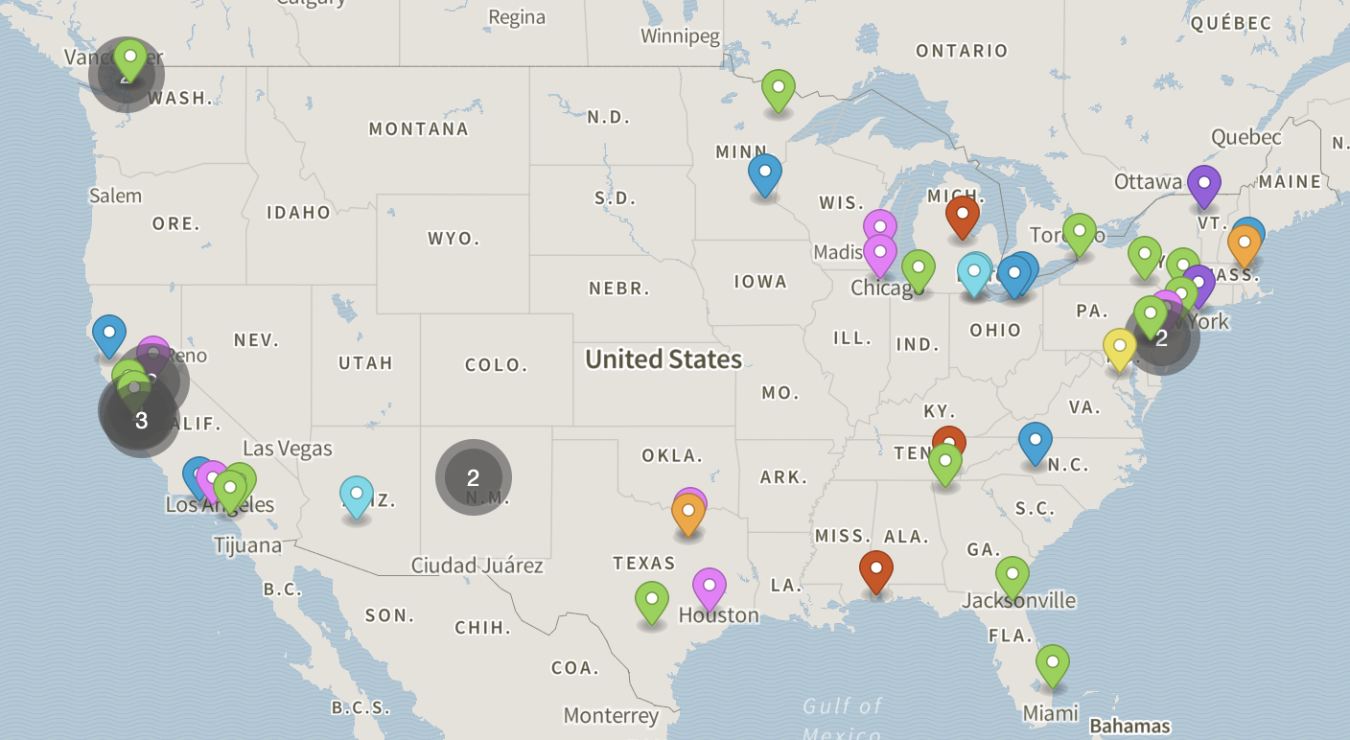

The U.S. Solar Photovoltaic Manufacturing Map displays active manufacturing sites that contribute to the domestic solar PV supply chain. The sector, subsector, facility type, and manufacturing capacity are provided for each site.

Why is Solar Manufacturing Important?

Building a robust solar manufacturing sector and supply chain in America supports the U.S. economy. It also helps America meet rising demand for secure, affordable, and reliable solar energy. Currently, the domestic PV manufacturing industry has the capacity to produce enough PV modules to meet U.S. demand, but there are gaps in the crystalline silicon value chain. Expanding domestic manufacturing capacity and closing gaps in the supply chain will boost the U.S. economy and create valuable manufacturing jobs.

A strong solar manufacturing sector in the U.S. will also decrease dependence on foreign energy supplies, which will improve energy security.

Research in Solar Manufacturing

The U.S. Department of Energy (DOE) Solar Energy Technologies Office (SETO) funds research projects that boost domestic manufacturing competitiveness and help America compete on a global scale. Projects support proof-of-concept development and technology validation in addition to advancing entirely new manufacturing processes. This includes conducting techno-economic analysis and other evaluations of supply chains, infrastructure, and workforce. Learn more about SETO’s manufacturing funding programs below:

- American-Made Solar Prize – AMSP is a prize competition designed to revitalize U.S. solar manufacturing through a series of contests and the development of a diverse and powerful support network. Contestants can win cash prizes as well as vouchers that may be redeemed for work at a national lab.

- American-Made Perovskite Startup Prize – this $3 million prize competition was designed to accelerate the growth of the U.S. perovskite industry and support the rapid development of solar cells and modules that use perovskite materials.

- SETO Fiscal Year 2022 Solar Manufacturing Incubator Funding Program – accelerating commercialization of innovative product ideas that can increase U.S. domestic manufacturing across the solar industry supply chain and expand private investment in America's solar manufacturing sector.

- Solar Energy Technologies Office Fiscal Year 2021 Systems Integration and Hardware Incubator Funding Program – enabling solar energy to contribute to the reliability and resilience of the nation’s electricity grid and continue driving down costs, while developing next-generation solar technologies and increasing U.S. solar manufacturing.

- Solar Energy Technologies Office Fiscal Year 2020 Funding Program – bringing prototypes to a pre-commercial stage and retiring business/market risks to spur investments, patents, publications, and jobs.

- Solar Energy Technologies Office Fiscal Year 2019 Funding Program – developing robust prototypes that will be able to prove the critical functions of the final products and attract private-sector investment.

- Solar Energy Technologies Office Fiscal Year 2018 Funding Program – developing and testing new ways to accelerate the integration of emerging technologies into the solar industry.

- Small Business Innovation Research and Small Business Technology Transfer – encouraging U.S.-based small businesses to engage in high-risk, innovative research and development of technology with the potential for future commercialization.

- Technology Commercialization Fund – leveraging funding across the entire Department of Energy to mature promising energy technologies developed at DOE’s national labs, in partnership with private companies, with the potential for high impact.

In addition, SETO has supported the development of the American-Made Network, which is comprised of national labs, incubators, investors, and seasoned industry mentors. It provides technical insight, product validation, and strategic support to entrepreneurs working with SETO.

Additional Resources

- The Advanced Materials and Manufacturing Technologies Office (AMMTO) supports a globally dominant U.S. manufacturing and industrial base for a resilient energy system and secure supply chain.

- The National Renewable Energy Laboratory’s Solar Manufacturing Cost Analysis analyzes manufacturing costs associated with PV cell and module technologies and solar-coupled energy storage technologies.

- The U.S. Manufacturing of Advanced Perovskites (US-MAP) Consortium accelerates domestic commercialization of perovskite technologies by providing access to comprehensive research capabilities that establish a solid technical foundation.