As we embark on a new fiscal year, we’d like to share some of our key accomplishments from Fiscal Year 2019.

Wind Energy Technologies Office

September 30, 2019The U.S. Department of Energy (DOE) Office of Energy Efficiency and Renewable Energy’s Wind Energy Technologies Office (WETO) provides global leadership in fundamental wind energy science research, development, and validation activities that enable low-cost wind energy. The office pursues opportunities across all U.S. wind sectors—land-based utility-scale wind, offshore wind, distributed wind, and system integration. As we embark on a new fiscal year (the federal government fiscal year runs from October to September), we’d like to share some of our key accomplishments from Fiscal Year 2019.

Josh Bauer, NREL

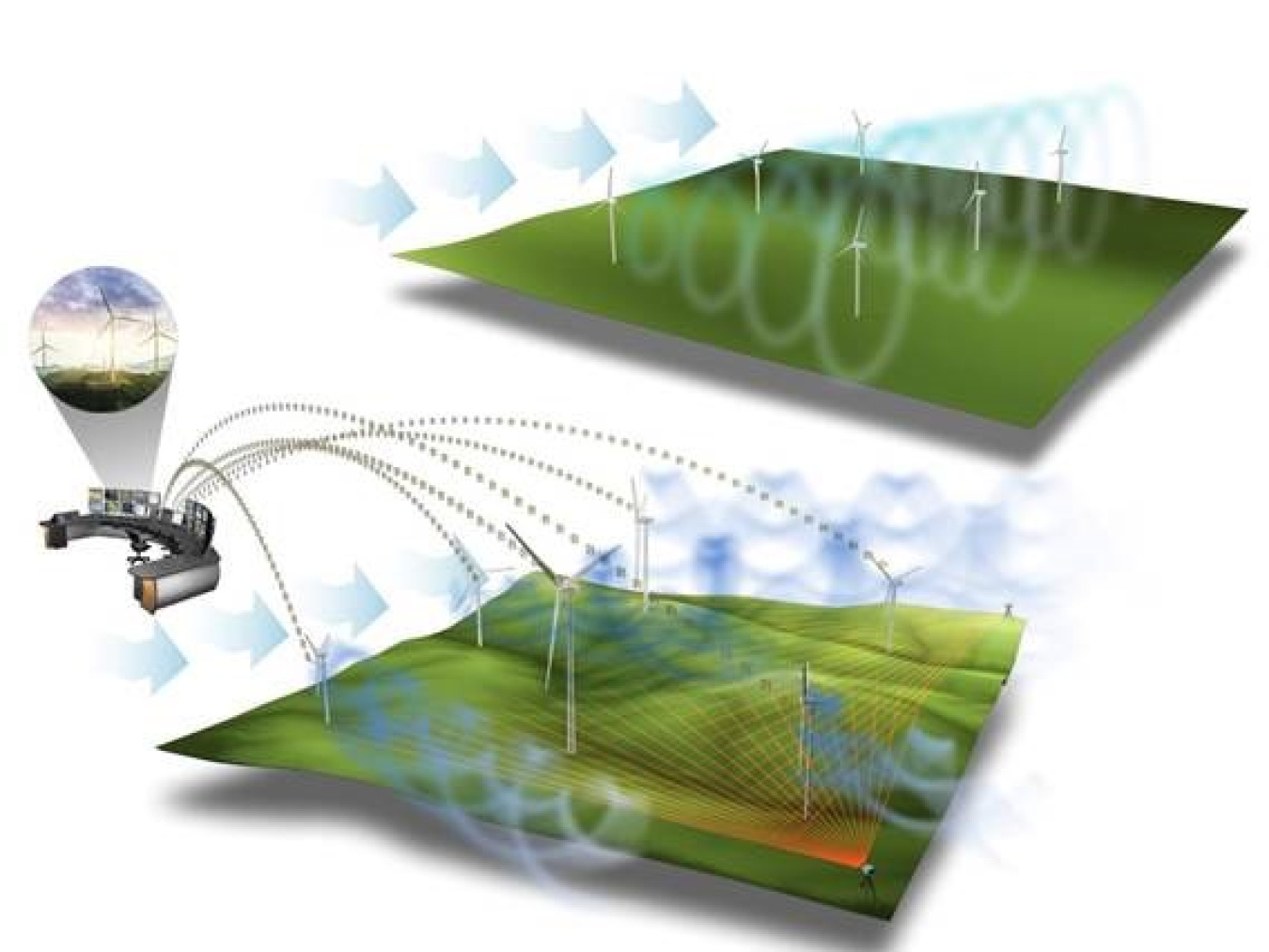

Wind Plant Controls

The Wind Energy Technologies Office (WETO) demonstrated how wake steering—a form of wind plant control that coordinates wind turbines within a plant—can increase plant output. The technique was pioneered by DOE and its National Renewable Energy Laboratory (NREL). The results of field trials at a commercial NextEra wind plant were consistent with supercomputer modeling simulations from WETO’s Atmosphere to Electrons initiative. The trials showed that coordinating the control of individual turbines through wake steering can improve the performance of an entire wind plant, increasing annual energy production by 1–2%. Such improvements can increase annual profits by $1 million or more, depending on the plant size and design. The modeling suggests, further, that an even greater gain of an additional 2–5% annual energy production is possible using a new “wind plant consensus” control strategy, which leverages turbine-to-turbine communications under field operating conditions.

Tall Wind

Through WETO’s Tall Wind initiative, innovations in taller wind towers and larger rotors can open up new areas of the country to wind power development, while boosting output elsewhere. WETO worked with DOE’s Berkeley Lab and DNV GL to study key design, manufacturing, and transportation options to facilitate the use of longer blades, and with NREL to understand the opportunities for increasing tower heights to 110–140 meters.

Materials Science

DOE’s Sandia and Oak Ridge National Laboratories concluded a two-year study demonstrating the commercial viability of cost-competitive carbon fiber composites tailored for use in wind turbine blades. The material—a heavy-tow textile carbon fiber—has improved mechanical properties compared to baseline carbon fiber materials and can provide system-level benefits in the manufacture of long, slender wind turbine blades.

Lightweight Generators

WETO selected three projects to develop more efficient, smaller, and lighter-weight generators that can lower costs and make wind power more affordable. WEG is developing a direct drive generator and American Superconductor and GE are developing superconducting generators.

Windpower Engineering

Reliability R&D

Gearbox failures remain leading cause of wind turbine downtime, primarily driven by cracks forming in the bearings. A WETO-funded multi-lab and industry project to understand bearing failures in wind turbine gearboxes developed a methodology to calculate bearing damage and the probability of bearing failure. This methodology enables a reliability assessment and prognosis of bearing axial cracking in individual wind turbines. It also yields a forecast of reliability, which can inform bearing design, controller settings, and turbine operations.

Jon Keller, NREL

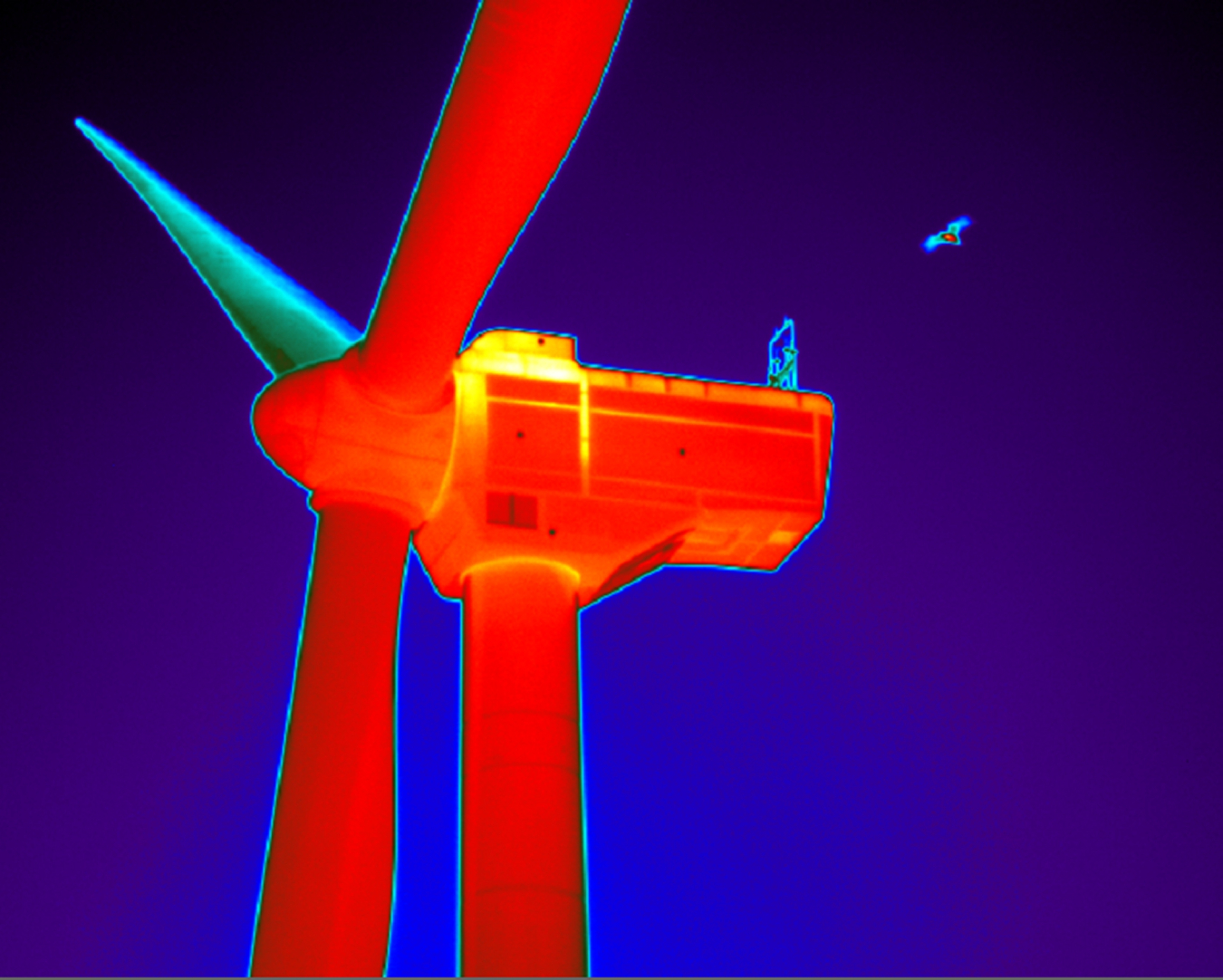

Autonomous Inspection

Randy Montoya

A WETO-funded project at DOE’s Sandia National Laboratories deployed and started testing a second-generation robot-deployed autonomous inspection system for wind turbine blades. The “crawler” robot moves along the blade and uses cameras to inspect surface damage and ultrasonic imaging to detect damage inside the blades. Wind turbines are often deployed in remote locations, and their blades—which are some of the largest single-piece composite structures in the world—are subject to weather and other forms of damage. The autonomous system reduces the need for manual inspections, which can be costly and time-consuming.

Offshore Wind

Dennis Schroeder, NREL

WETO has partnered with the New York State Energy Research and Development Authority to launch a $41-million offshore wind R&D consortium. The R&D will address U.S.-specific challenges such as offshore wind plant technology development, innovative wind resource and site characterization methodologies, and advanced technology solutions for installation, operation, maintenance, and supply chain. In 2019 the Consortium launched its first set of RFPs, selected one funding award, and hired its Executive Director.

Distributed Wind

WETO and its National Renewable Energy Laboratory led the development of a new task under the International Energy Agency’s (IEA’s) Wind Technical Collaboration Program, which was approved by IEA in March, 2019. Task 41: Enabling Wind to Contribute to a Distributed Energy Future will be a nine-country collaboration led by NREL to support distributed wind turbine design standards development, integration of wind with other distributed energy resources in microgrid applications, and establishment of a data sharing catalog.

Environmental Impacts R&D

M R Schirmacher

WETO awarded $7 million in federal funds to 10 projects that will reduce environmental compliance costs and environmental impacts of land-based and offshore wind energy. This marks the largest funding in work of this kind in WETO history. This research will advance the further development and improvement of deterrent technologies to keep bats safe around wind turbines, advance smart curtailment strategies to minimize energy loss from curtailment and wind plant environmental impacts to bats and resolve key gaps in offshore wind environmental monitoring capabilities. This work builds on previous research efforts funded by DOE that have resulted in commercial deterrent technologies and curtailment strategies that reduce impacts to bats at wind plants.

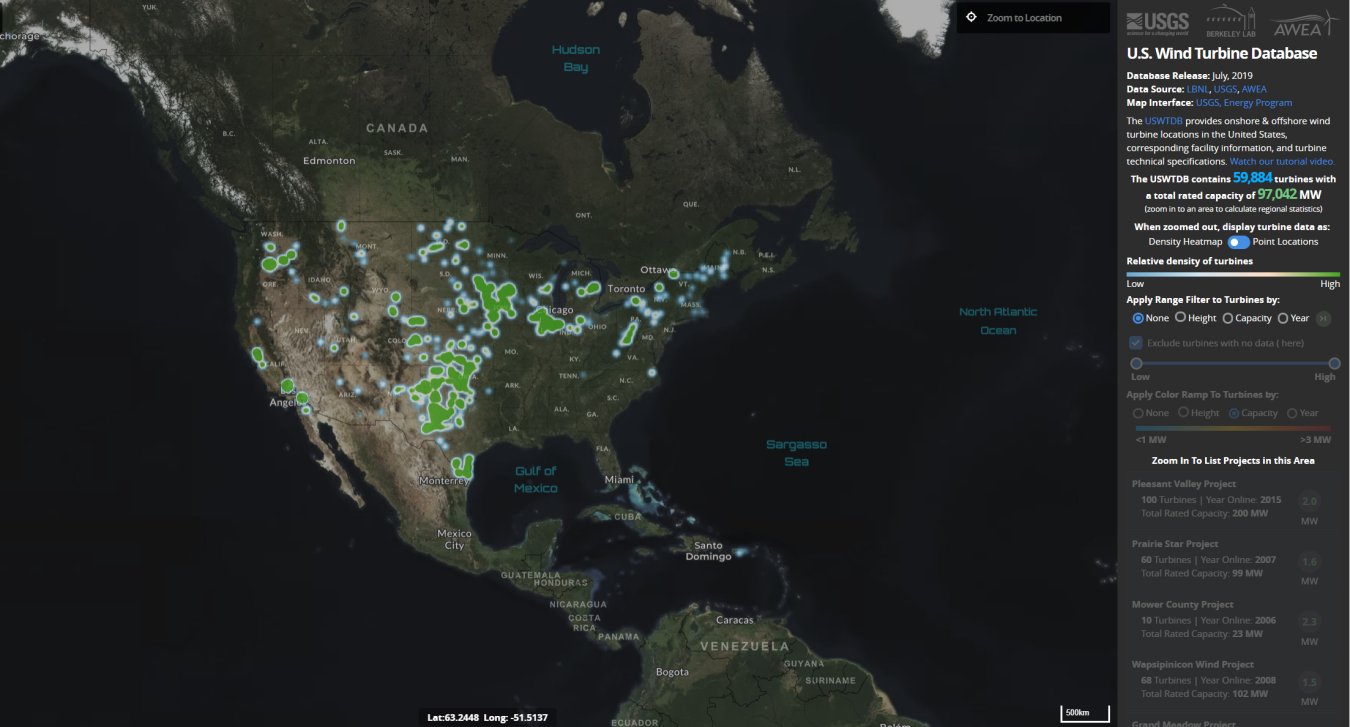

U.S. Wind Turbine Database

The U.S. Wind Turbine Database—the primary source for industry and government in evaluating the impacts of wind development on radar systems for flight safety, national security, and weather—reached 2.5 million user hits.

U.S. Geological Survey

David Mazel, Regulus Group

Radar Interference Mitigation

Federal inter-agency research efforts, led by the U.S. Department of Defense and DOE in partnership with the Federal Aviation Administration, the National Oceanic and Atmospheric Administration, and the Bureau of Ocean Energy Management, are aimed at minimizing the impacts of wind turbines on radar systems. Recent promising results testing small infill radars suggest that these systems could be ready to integrate into air traffic control (ATC) operations to mitigate the impacts of wind development on ATC radars in the next few years.

Grid Services

NREL and Avangrid demonstrated wind energy’s capability to provide essential reliability services at a commercial wind plant in California. Earlier tests showed that wind could provide active power ramping support, as well as voltage and reactive power support. In August 2019, the California grid operator completed the last of a series of tests, which demonstrated, additionally, the ability for wind turbine generators to provide frequency regulation service.

Grid Operator Tools

NREL released a beta version of WindView, an open source visualization tool that unifies probabilistic wind forecast data with map-based visualization. Through an interactive map, grid operators can view aggregated forecasts for selected wind plants and set up customizable alerts, facilitating their decision making as the amount of wind energy on the grid increases. The tool was developed by DOE’s Argonne National Laboratory and NREL.

Werner Slocum, NREL

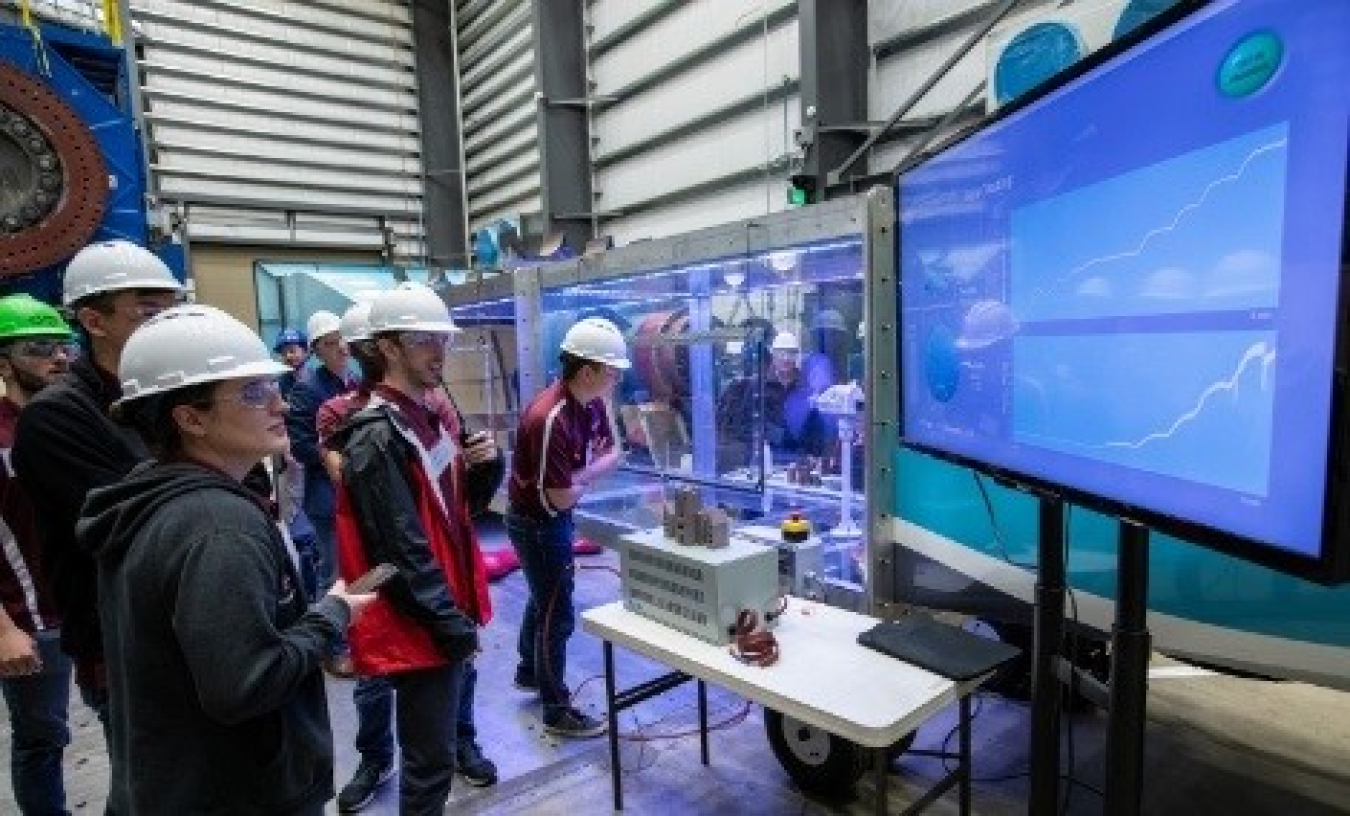

STEM and Workforce Development

WETO hosted the 6th annual Collegiate Wind Competition at the NREL Flat Irons campus in May 2019. Using NREL’s custom-built wind tunnels, students from 12 schools tested the performance of wind turbines that they designed and built. The schools also participated in plant design and siting competitions. NREL also released a WETO-funded report detailing current and future wind workforce training needs and gaps.

Here's a sneak peek of what we have planned for Fiscal Year 2020.

Next-Generation Wind Plants: Improve the performance and reliability of next-generation wind plants by investigating systems-level interactions influenced by atmospheric conditions, variable terrain, and machine-to-machine wake interactions.

Technology Innovation: Focus on fundamental R&D in the areas of controls, sensors, algorithms, materials, and manufacturing to lower costs and improve operational performance.

Offshore Wind R&D: Address U.S.-specific offshore wind challenges, including substructure technologies, installation cost and risks, technologies to reduce on-site O&M, and design standards for extreme marine conditions unique to the United States.

Distributed Wind R&D: Reduce costs and maximize the value and resiliency of grid-connected micro-grids powered by wind-centered hybrid distributed energy systems.

Grid: Continue Grid Modernization Initiative activities and address R&D needs for better integration of wind generation through co-optimized wind plant operation, integrating multiple technologies, flexible transmission utilization, and wind plant cybersecurity.

Environmental & Siting R&D: Address wind–radar challenges and develop technical solutions to reduce environmental compliance costs.