The Wind Energy Technologies Office (WETO) works with industry partners to increase the performance and reliability of next-generation wind technologies while lowering the cost of wind energy. The office's research efforts have helped to increase the average capacity factor (a measure of power plant productivity) from 22% for wind turbines installed before 1998 to an average of nearly 35% today, up from 30% in 2000. Wind energy costs have been reduced from over 55 cents (current dollars) per kilowatt-hour (kWh) in 1980 to an average of under 3 cents per kWh in the United States today. To ensure future industry growth, wind industry technology must continue to evolve, building on earlier successes to further improve reliability, increase capacity factors, and reduce costs. This page describes the goal of WETO's utility-scale wind technology research efforts and highlights some of its recent projects.

Wind energy technologies available for licensing from U.S. Department of Energy laboratories and participating research institutions can be found on the DOE's Office of Energy Efficiency and Renewable Energy's Energy Innovation Portal. View all WETO next-generation technologies research and development projects by visiting the WETO Projects Map and selecting Program Area: Next-Generation Technology Development and Manufacturing.

Research Project Highlights

These are some of the key research project highlights from the program's next-generation wind technology research.

Prototype Development

Learn more about how DOE's National Renewable Energy Laboratory is testing the causes of drivetrain failures.

Modern wind turbines are increasingly cost-effective and more reliable, and have scaled up in size to multi-megawatt power ratings. Since 1999, the average turbine generating capacity has increased, with turbines installed in 2016 averaging 2.15 MW of capacity. WETO research has helped facilitate this transition, through the development of longer, lighter rotor blades, taller towers, more reliable drivetrains, and performance-optimizing control systems.

During the past two decades, the office has worked with industry to develop a number of prototype technologies, many of which have become commercially viable products. One example is the GE Wind Energy 1.5-megawatt (MW) wind turbine. Since the early 1990s, the program worked with GE and its predecessors to test components such as blades, generators, and control systems on generations of turbine designs that led to GE's 1.5-MW model, which has constituted approximately half of the nation's installed commercial wind energy fleet and is a major competitor in global markets.

Component Development

WETO worked with industry partners to improve the performance and reliability of system components. Knight and Carver's Wind Blade Division in National City, California, worked with researchers at the Department of Energy's Sandia National Laboratories to develop an innovative wind turbine blade that has led to an increase in energy capture by 12% The most distinctive characteristic of the Sweep Twist Adaptive Rotor (STAR) blade is a gently curved tip, which, unlike the vast majority of blades in use, is specially designed to take maximum advantage of all wind speeds, including slower speeds.

More recently, to support the development of more reliable gearboxes, the program has worked with several companies to design and test innovative drivetrain concepts. Through the support of $47 million in DOE funding, the nation's largest and one of the world's most advanced wind energy testing facilities was opened at Clemson University to help speed the deployment of next- generation energy technology, reduce costs for manufacturers, and boost global competitiveness for American companies.

Innovation in the design and manufacturing of wind power generation components continues to be critical to achieving our national renewable energy goals.

Highlighted Project: Innovation in the design and manufacturing of wind power generation components continues to be critical to achieving our national goals. As a result of this challenge, the U.S. Department of Energy's Wind Energy Technologies Office and Advanced Manufacturing Office are partnering with public and private organizations to apply additive manufacturing, commonly known as 3D printing, to the production of wind turbine blade molds. The traditional method of blade design requires the creation of a plug, or a full size representation of the final blade, which is then used to make the mold. Creating the plug is one of the most time-intensive and labor intensive processes in wind blade construction, so 3D printing saves these critical resources.

Utility-Scale Research Turbines

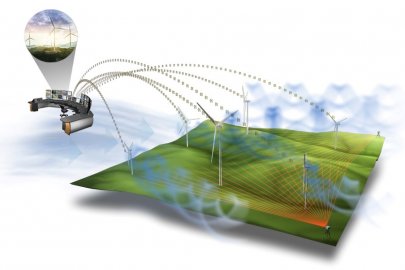

The National Renewable Energy Laboratory's National Wind Technology Center (NWTC) has helped pioneer wind turbine component, systems, and modeling methods that have driven industry acceleration. The facility offers multiple test sites, several dynamometers, onsite manufacturing resources, and structural validation capabilities. Research conducted at the NWTC complements DOE's Atmosphere to Electrons (A2e) initiative, which targets significant reductions in the cost of wind energy through an improved understanding of the complex physics governing wind flow into and through wind farms. Innovative wind energy research at the NWTC includes:

- Using computational fluid dynamics to develop the Simulator for Wind Farm Applications and other modeling and controls tools, which help wind farm operators minimize the impact of turbine wake effects by investigate plant performance under a full range of atmospheric conditions. Studies have shown that by coordinating turbine controls to curtail wake effects, the overall wind power plant output could be increased by 4%–5%.

- Utilizing the controllable grid interface test system, which reduces wind turbine certification testing times and costs while providing system engineers with a better understand of how wind turbines, photovoltaic inverters, and energy storage systems react to disturbances on the electric power system.

- Analyzing offshore wind energy in the United States to illuminate industry needs, opportunities, and anticipated impacts in this burgeoning renewable power industry.

Small Wind Turbine Technology R&D and Testing

WETO has collaborated with NREL researchers and U.S. suppliers of distributed wind energy technologies to develop next-generation turbines and components, perform testing and certification, and commercialize products to make wind energy cost-competitive with other distributed energy technologies. Through an initiative called the Competitiveness Improvement Project (CIP), WETO funded the installation of three small wind turbines at the Flatirons campus in Colorado that will enable research on turbine design characteristics common to small wind turbines used in distributed applications.

International Collaboration

As a member of the International Energy Agency (IEA) Wind Energy Executive Committee, the office supports international wind energy research efforts by participating in 12 areas of wind energy research. The office's participation in these international research efforts provides U.S. researchers an opportunity to collaborate with international experts in wind energy, exchange recent technical and market information, and gain valuable feedback for the U.S. industry. For more information on IEA activities, visit the International Energy Agency website.