the Savannah River Site (SRS) have developed a system that improves protection for workers who handle and dispose of contaminated laboratory waste.

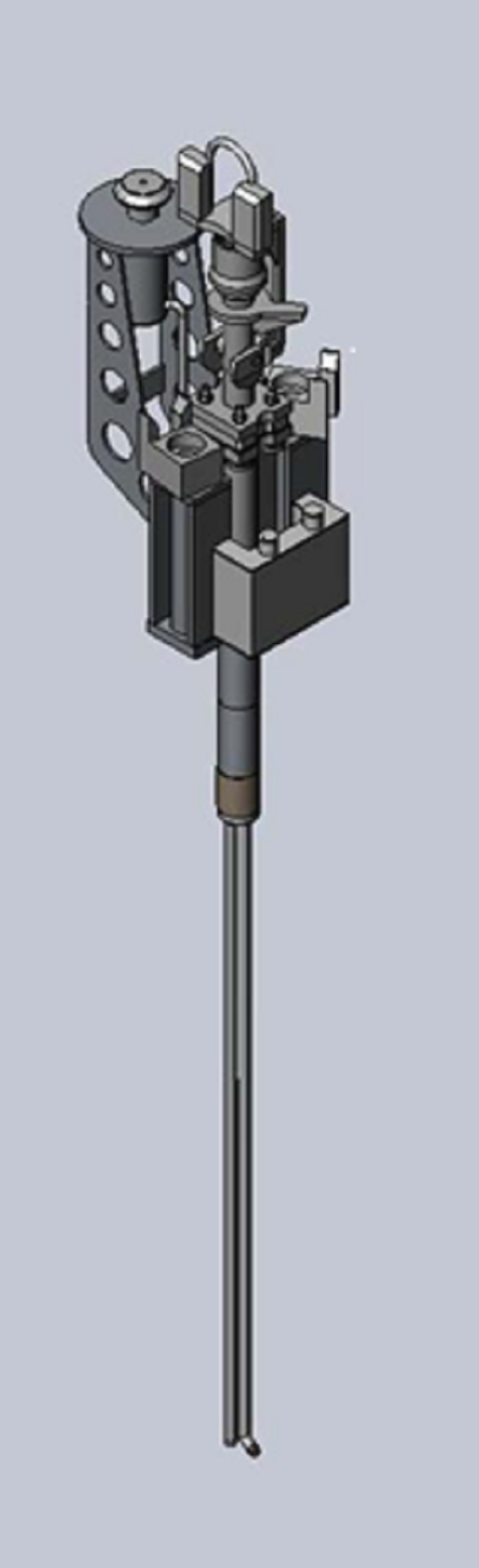

Innovative equipment known as “bubblers” have been improving liquid waste operations at EM’s Savannah River Site.

Operations of the Salt Waste Processing Facility at the Savannah River Site represents a leap forward in DOE’s ability to tackle tank waste.

EM and prime contractor Parsons Corporation are poised to begin transferring radioactive material to the Salt Waste Processing Facility.

EM has successfully integrated the liquid waste treatment system with the Salt Waste Processing Facility.

DOE and the University of South Carolina-Aiken (USCA) unveiled a 3-D model of the proposed Advanced Manufacturing Collaborative facility last week.

DOE has completed the first application of its science-based approach to managing reprocessing waste with the safe and successful shipment.

EM and its liquid waste contractor at the Savannah River Site (SRS) have completed significant upgrades to accelerate treatment.

Built in the early 1990s, the metal buildings at SRS were no longer needed for DOE missions.

EM liquid waste contractor at the Savannah River Site are advancing a project to double-stack canisters containing high-level radioactive waste.