In 2019, North Augusta High School student Kathryn McGee volunteered for an EM contractor’s outreach program that introduces female students to careers in science, technology, engineering and math (STEM). She’s now a newly hired Savannah River Site (SRS)

George Larsen and his project “Hydrogen Process Imagine Using Magnetic Fields” received this year’s Savannah River National Laboratory (SRNL) Laboratory Directed Research and Development (LDRD) Most Valuable Project (MVP) Award.

Savannah River Site employees gradated from an EM contractor's Mentorship Program cohort.

Early career researchers at the Savannah River National Laboratory participate in a Research SLAM providing a summary of their scientific work before a panel of judges.

Contractor employees supporting the EM program at the Savannah River Site (SRS) recently reevaluated deactivation plans for legacy facilities in the site’s F Area, prompting a change in direction resulting in significant cost savings.

The University of Georgia Savannah River Ecology Laboratory (SREL) and other collaborators have successfully released offspring of confiscated eastern box turtles at the Savannah River Site (SRS).

More than 265 minority serving institutions (MSI) faculty and students, DOE personnel and Savannah River National Laboratory (SRNL) employees recently gathered for the EM Minority Serving Institutions Partnership Program (EM MSIPP) Achievement Workshop.

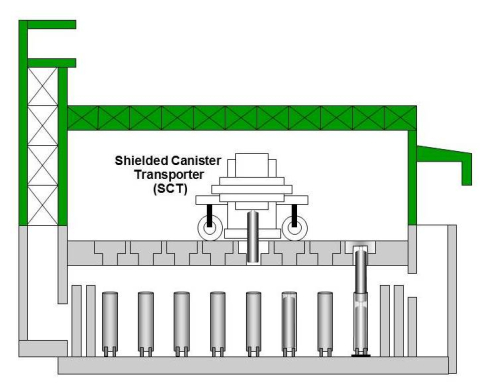

EM has marked a major achievement in the effort to expand interim storage of canisters of vitrified high-level waste at the Savannah River Site (SRS) while saving taxpayer dollars.

Nearly 50 high-performing, qualifying interns from an EM contractor’s paid summer internship program were recently offered a chance to turn full service during the annual “Signing Day” event held at the Savannah River Site (SRS).

EM and a contractor at the Savannah River Site (SRS) recently finished the cleanup of a discharge canal, a project that successfully completes environmental remediation of the Lower Three Runs stream system.