Many design features and technologies make windows more energy efficient and improve the durability, aesthetics, and functionality. When selecting new windows, consider the frame materials, the glazing or glass features, gas fills and spacers, and the type of operation. All of these factors will influence the overall energy-related properties of the window. To assess and compare the overall window properties, look for an NFRC label.

Frames and Sash

Improving the thermal resistance of the frame can contribute to a window's overall energy efficiency, particularly its heat loss rate or U-factor. There are advantages and disadvantages to all types of frame materials, but vinyl, wood, fiberglass, and some composite frame materials provide greater thermal resistance than metal.

Composite Frames

Composite window frames consist of composite wood products, such as particleboard and laminated strand lumber, and some are mixed with polymer plastics. These composites are very stable, they have the same or better structural and thermal properties as conventional wood, and they have better moisture and decay resistance.

Fiberglass Frames

Fiberglass window frames are dimensionally stable and have air cavities that can be filled with insulation, giving them superior thermal performance compared to wood or uninsulated vinyl.

Vinyl Frames

Vinyl window frames are made of polyvinyl chloride (PVC) with ultraviolet light (UV) stabilizers to keep sunlight from breaking down the material. Vinyl window frames do not require painting and have good moisture resistance. The hollow cavities of vinyl frames can be filled with insulation, which makes them thermally superior to standard vinyl and wood frames.

Wood Frames

Wood window frames insulate relatively well, but they require regular maintenance, although aluminum or vinyl cladding reduces maintenance requirements. Metal clad wood frames may have slightly lower thermal performance.

Glazing or Glass

In most windows the most important decision regarding energy efficiency is the selection of the glazing. Based on various window design factors such as window orientation, climate, building design, etc., you may even want to choose different types of glazing for different windows throughout your home.

For more detailed information about glazing options visit the Efficient Windows Collaborative to learn about the specific properties and efficiency of different glazing options.

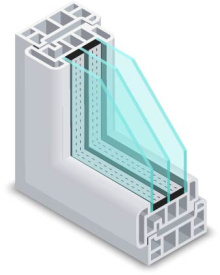

While single glazing is common in older buildings, virtually all new efficient buildings use double or triple glazing units. The "insulating glazing units", or IGUS, are available in a wide range of properties based on the type of glass selected, the coatings on the glass, the gas used to fill the space between the panes, and the spacers that keep the glazing separated. Below are some of the most common coatings and technologies you may find when shopping for windows:

Insulated

Insulated window glazing refers to windows with two or more panes of glass. To insulate the window, the glass panes are spaced apart and hermetically sealed, leaving an insulating air space. Insulated window glazing primarily lowers the U-factor, but it also lowers the SHGC.

Low-Emissivity Coatings

Low-emissivity (low-e) coatings on glass control heat transfer within the insulated glazing. Windows manufactured with low-e coatings typically cost about 10% to 15% more than regular windows, but they reduce energy loss by as much as 30% to 50%.

A low-e coating is a microscopically thin, virtually invisible, metal or metallic oxide layer deposited directly on the surface of one or more of the panes of glass. The low-e coating lowers the U-factor of the window, and can manage the daylight transmittance as well as the solar heat gain through the glazing system. Different types of low-e coatings have been designed to allow for high solar gain, moderate solar gain, or low solar gain, and and they can also be tuned to control the amount of visible daylight transmitted.

Although low-e coatings are usually applied during manufacturing, some are available for do-it-yourselfers. These films are inexpensive compared to total window replacements, last 10 to 15 years without peeling, save energy, reduce fabric fading, and increase comfort.

Spectrally Selective Coatings

In those climate where cooling loads dominate, you will want a glazing that provides daylight and view but transmits as little of the sun's non-visible infrared radiation as possible, Some low-E coatings are designed to be spectrally selective, filtering out 40% to 70% of the heat normally transmitted through insulated window glass or glazing while allowing the full amount of daylight.

Gas Fills and Spacers

In order to minimize heat transfer between the interior and exterior of the window, the space between glazing layers, usually about 1/2", is filled with argon or krypton gas; both are inert, non-toxic, clear, and odorless.

Argon is most commonly used because it is inexpensive and performs well in the typical 1/2" space. Krypton can be used when the space in thinner than usual - usually about ¼ inch. It has better thermal performance than argon but is also more costly.

Spacers with associated sealants are used to keep the layers of glazing the correct distance apart. In addition, they provide accommodation for thermal expansion and pressure differences, while also preventing moisture and gas leaks.

A variety of spacers are available with different impacts on the window U-factor. Look for "warm edge" spacers which are designed to lower the window U-factor and reduce condensation at the edge of the window. See the Efficient Windows Collaborative for more information on the different spacer types.

- Window Selection Tool

- Climate Zone Recommendations - Efficient Windows Collaborative

- Product Ratings - National Fenestration Rating Council

- Energy Performance Label - National Fenestration Rating Council

- Windows and Daylighting - Lawrence Berkeley National Laboratory

- Window Technologies: Frame Types - Efficient Windows Collaborative

Subscribe to receive updates from Energy Saver, including new blogs, updated content, and seasonal energy saving tips for consumers and homeowners.