Donning devices that help relieve stress on workers’ muscles and joints or create a virtual reality simulating a worksite, more than 40 members of a team recently met in person for the first time since fiscal 2020 to evaluate technology.

EM’s liquid waste contractor at Savannah River Site (SRS) has partnered with Claflin University to challenge the students to improve the method for removing and replacing radioactively contaminated equipment inside the Salt Waste Processing Facility.

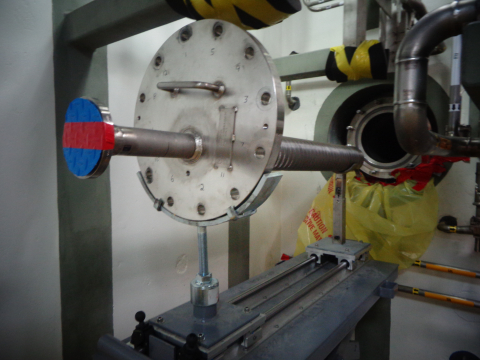

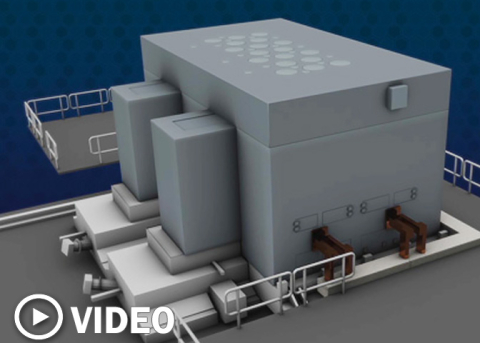

EM Office of River Protection (ORP) tank operations contractor Washington River Protection Solutions (WRPS) is ready to begin assembling additional melters to support the Direct-Feed Low-Activity Waste (DFLAW) Program at the Hanford Site.

Unifying laboratory operations and streamlining analytical processes are changing the game for EM’s liquid waste program at the Savannah River Site (SRS).

The liquid waste contractor at Savannah River Site (SRS) met an EM 2022 priority with the recent completion of concrete placements on Saltstone Disposal Unit (SDU) 9.

Crews at the Hanford Site have begun heating up the world’s largest melter that will transform radioactive and chemical tank waste currently stored in underground tanks into a vitrified glass form safe for disposal.

Workers with EM Office of River Protection (ORP) tank operations contractor Washington River Protection Solutions (WRPS) are “going green” with new battery-powered electric generators on the Hanford Site.

EM contractor Hanford Laboratory Management and Integration (HLMI), which runs the Hanford Site’s 222-S Laboratory, received the Voluntary Protection Program (VPP) Superior Star award from DOE at a recent national conference in Washington, D.C.

Hanford Site leadership participated in a National Cleanup Workshop panel discussion focused on current and future achievements at the site.

Washington River Protection Solutions (WRPS) recently won its sixth Voluntary Protection Program (VPP) Innovation Award.