DOE recently bestowed eight EM teams with the Secretary of Energy Achievement Award, recognizing projects at the Idaho, Savannah River and Hanford sites as well as a group of employees who revamped and expanded EM’s Minority Serving Institutions.

The EM Office of River Protection (ORP) recently took another step in reducing environmental risk at the Hanford Site, as workers began retrieving radioactive and chemical waste from the fourth & final underground single-shell storage tank in the AX Farm.

As crews ready a liquid waste treatment facility at the DOE Idaho National Laboratory Site for sodium-bearing waste processing, EM is preparing to construct a new building to provide additional capacity for the safe storage of treated waste material.

Crews recently performed a second run using water to test for receiving sodium hydroxide at the Waste Treatment and Immobilization Plant (WTP) Effluent Management Facility (EMF) on the Hanford Site.

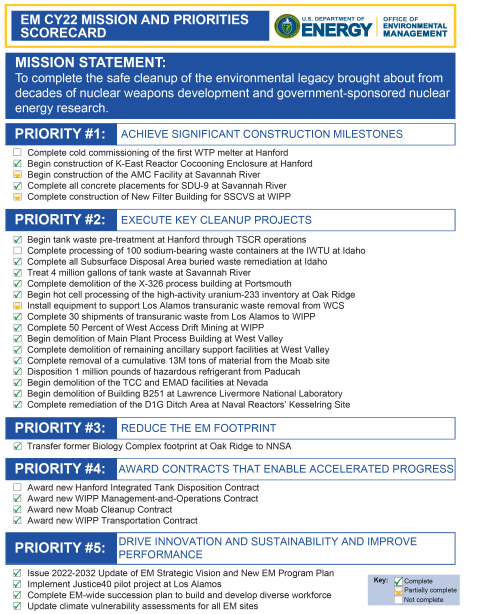

EM achieved the majority of its priorities for calendar year (CY) 2022, completing challenging work that demonstrates visible and effectual progress as the program focuses on some of its most difficult remaining challenges.

EM received a fiscal year 2023 (FY23) budget of $8.3 billion, a 5% increase over the amount the cleanup program received for FY22.

Hanford Site crews recently completed testing on a transfer line communications system between the Waste Treatment and Immobilization Plant (WTP) and the nearby tank farm, or large group of underground storage tanks, where pretreated waste is being stored

Ten days after beginning a heat-up process to prepare for radiological operations at the Integrated Waste Treatment Unit (IWTU), operators noticed a small leak of non-radioactive, non-hazardous solids in a cell.

After more than 30 years of mitigating the most pressing environmental risks, EM is approaching a crossroads, shifting to remaining work that involves some of the toughest and most expensive challenges.

EM’s radioactive liquid waste treatment facility at the Idaho National Laboratory Site will begin its final heat-up this month before initiating radiological operations early next year.