An EM contractor at the Savannah River Site (SRS) continues to find ways to improve its small business mentor-protégé program, now in its sixth year.

The liquid waste contractor at Savannah River Site (SRS) met an EM 2022 priority with the recent completion of concrete placements on Saltstone Disposal Unit (SDU) 9.

A graduate in welding from South Carolina’s only historically black technical college is pursuing her passion in the Savannah River Site’s (SRS) Liquid Waste Program.

EM Senior Advisor William “Ike” White praised recent progress in EM’s cleanup work and laid out a roadmap of future success as he kicked off the first full day of the annual National Cleanup Workshop in Arlington, Virginia on Sept. 22.

Eight managers leading cleanup at EM sites across the DOE complex highlighted successes and shared challenges over the past year during a roundtable discussion at the National Cleanup Workshop.

EM partners near the Hanford, Los Alamos, Portsmouth and Oak Ridge sites highlighted reuse opportunities in the cleanup program during a panel session at the National Cleanup Workshop.

EM is slated to decommission a building at the Savannah River Site (SRS) containing residual plutonium once used to power deep space missions after workers finished deactivating the facility.

EM crews at the Savannah River Site (SRS) recently demolished a former coal handling system whose removal further shrinks the legacy footprint at the 300-square-mile nuclear reservation.

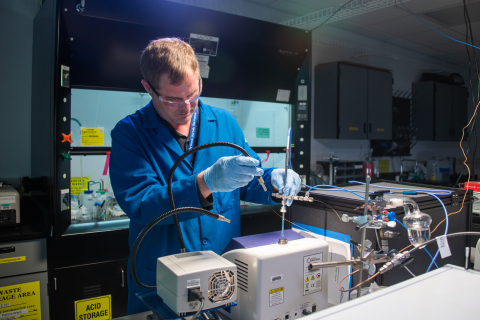

A national laboratory at the Savannah River Site that supports advancements in the EM cleanup mission has been awarded $3 million to further fundamental research capable of enabling new pathways for hydrogen storage and production technologies.

The first 36 students graduated from the EM Savannah River Site (SRS) liquid waste contractor’s Nuclear Fundamentals Certificate program this summer.