EM is draining the last large concrete basin at the Hanford Site.

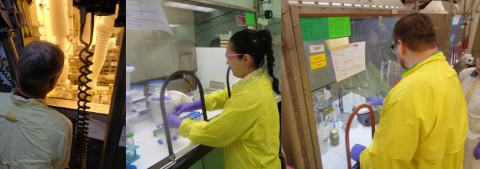

New chemical technologists at the Hanford Site’s 222-S Laboratory, operated by contractor Navarro-ATL, are engaged in a four-month education program.

Hanford workers recently used a robotic arm to help remove an old 34-foot pump from a large underground tank, called AP-102, that stores radiological and chemical waste.

Workers have finished removing radioactive waste from the 21st large underground storage tank as part of the massive cleanup of the Hanford Site in southeast Washington state.

The U.S. Department of Energy (DOE) Office of Environmental Management’s (EM) Hanford Site is this year’s recipient of the Presidential Migratory Bird Federal Stewardship Award, in recognition of the site’s migratory bird protection and artificial burrow systems for burrowing owls.

An after-school camp in Tri-Cities, Washington, is giving young women the tools to build a foundation — literally and figuratively — for a career in construction, strengthening the local pipeline for the next generation of Hanford Site workers.

Technicians at the Hanford Site’s 222-S Laboratory, operated by U.S. Department of Energy Office of Environmental Management contractor Navarro-ATL, are processing the second batch of radioactive tank waste samples in support of the Direct-Feed Low-Activity Waste (DFLAW) Program.

For more than a decade, the U.S. Department of Energy Office of Environmental Management’s Office of River Protection has collaborated with national and international laboratories, universities and glass industry experts to plan and prepare for 24/7 operations at the Waste Treatment and Immobilization Plant (WTP) at the Hanford Site.

Workers recently unloaded a shipment of more than 10,000 gallons of sodium hydroxide delivered to the Hanford Site’s Waste Treatment and Immobilization Plant (WTP). The liquid sodium hydroxide will be the first chemical fed into the plant’s melters to simulate Hanford tank waste.

The Emergency Management and Preparedness team with Hanford Site contractor Hanford Mission Integration Solutions (HMIS) gave a presentation at the 2024 Emergency Management Symposium.