The U.S. Department of Energy Office of Environmental Management Hanford Field Office is modernizing the 222-S Laboratory at the Hanford Site to enhance its capability, capacity and reliability for future cleanup work. August 26, 2025

Office of Environmental Management

August 26, 2025Updates to meet modern demands, support a sustainable future

RICHLAND, Wash. — The U.S. Department of Energy Office of Environmental Management (EM) Hanford Field Office (HFO) is modernizing the 222-S Laboratory at the Hanford Site to enhance its capability, capacity and reliability for future cleanup work.

The 70,000-square-foot facility, operated by HFO contractor Navarro-ATL, provides essential analytical services. Lab workers analyze a variety of samples, including air, liquid, soil, tank sludge, and biological materials, to aid safe cleanup decisions.

Built in 1951, Hanford’s lab required updates to meet modern demands. The multiyear modernization program includes upgrading lab equipment, improving infrastructure and renovating workspaces to improve efficiency and safety.

“The 222-S Laboratory is one of the few facilities in the nation capable of highly radioactive tank waste analysis,” said Jeff Cheadle, 222-S program manager with HFO. “These upgrades allow us to deliver valuable chemical and radiological data that support innovation and long term cleanup.”

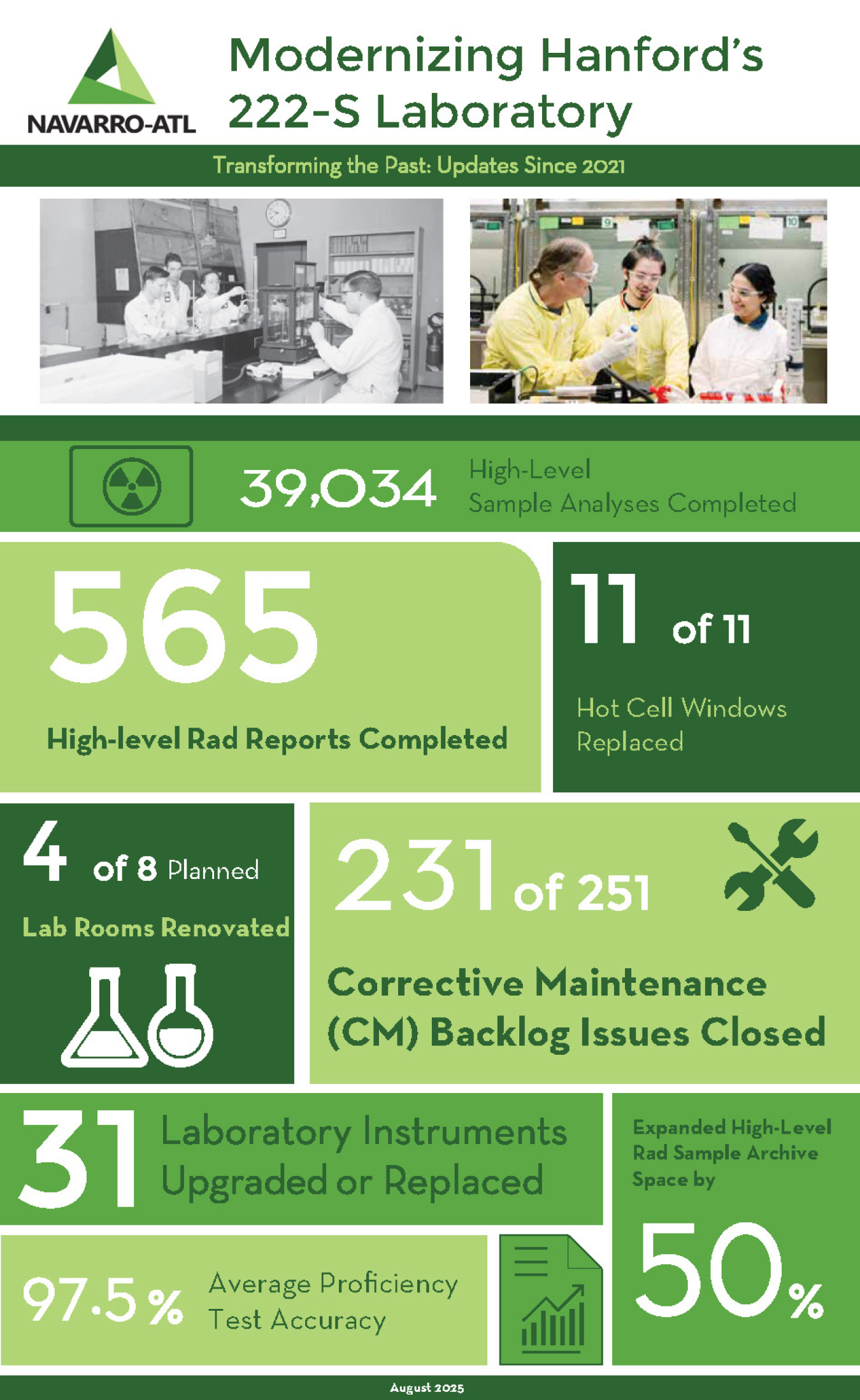

222-S Laboratory by the Numbers: This snapshot highlights key upgrades and maintenance completed to modernize the facility.

Recent improvements include renovating four workspaces from top to bottom, replacing equipment and instruments, installing new electrical and ventilation systems, and adding specialized lighting for high-precision work. Crews also replaced aging hot cell windows, which are thick shielded glass workers use to safely examine radioactive samples. The new windows are expected to last approximately 20 years.

“Replacing hot cell windows and related equipment has significantly improved safety and ergonomics for workers," said Ray Geimer, general manager of Navarro-ATL. “Future improvements will further enhance our ability to deliver highly radioactive analyses efficiently, timely and safely.”

Last year, the facility completed about 8,000 analytical measurements. That number is expected to grow as the lab supports the startup of Hanford’s Waste Treatment and Immobilization Plant, where liquid waste will be immobilized in glass for safe storage. To prepare, lab chemists introduced the Stir Bar method, which is safer, more efficient, and cuts analysis time from days to hours, resulting in cost savings.

To receive the latest news and updates about the Office of Environmental Management, submit your e-mail address.