EM Richland Operations Office (RL) contractor Central Plateau Cleanup Company (CPCCo) continues to make significant progress developing the equipment, tools and techniques to safely transfer nearly 2,000 radioactive cesium and strontium capsules.

Office of Environmental Management

February 7, 2023EM Richland Operations Office (RL) contractor Central Plateau Cleanup Company (CPCCo) continues to make significant progress developing the equipment, tools and techniques to safely transfer nearly 2,000 radioactive cesium and strontium capsules from an underwater basin in the Waste Encapsulation and Storage Facility (WESF) to a nearby dry-storage area at the Hanford Site.

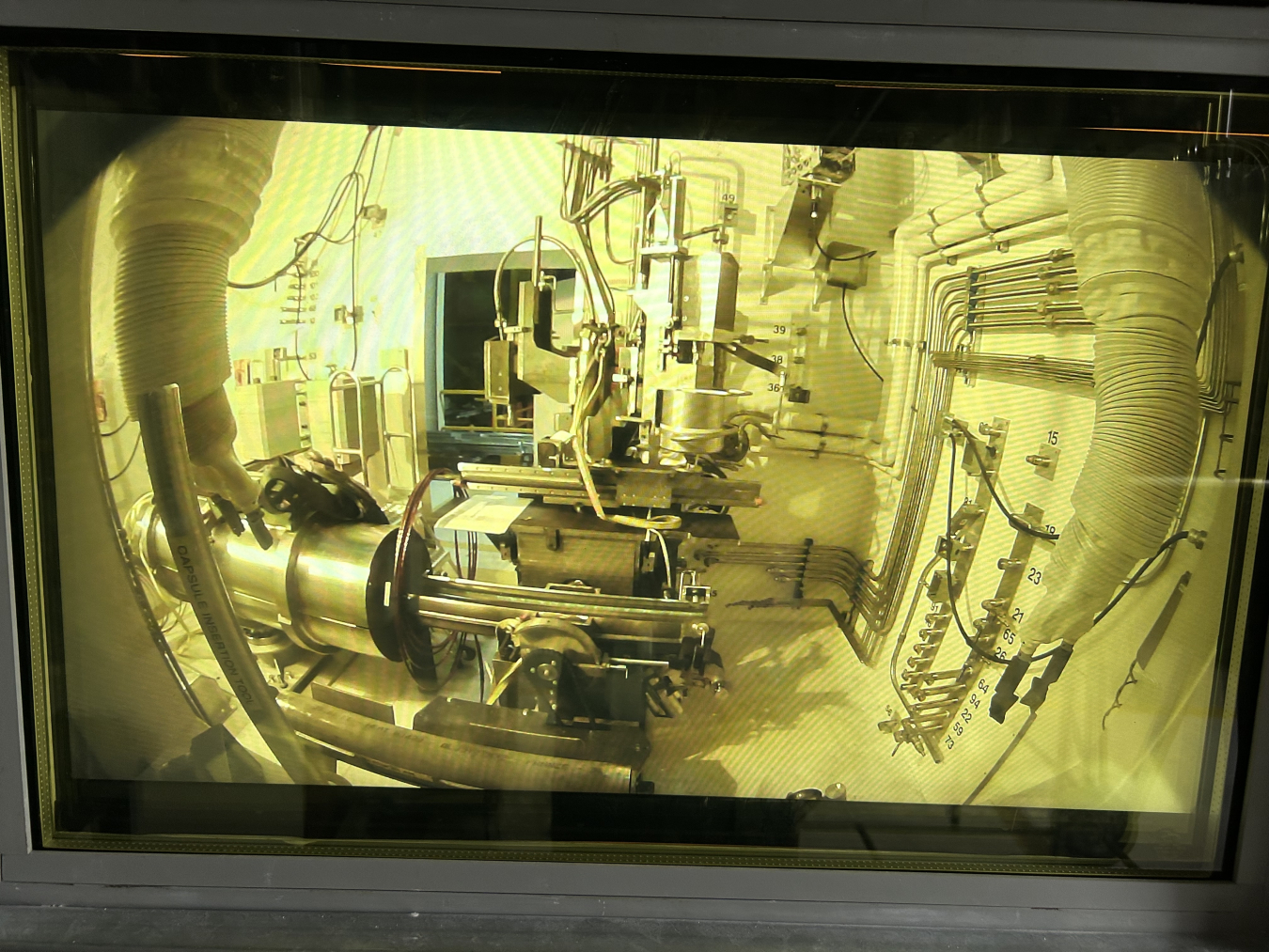

Several major components of a full-scale mock-up of the capsule transfer system recently arrived at Hanford’s Maintenance and Storage Facility for installation and testing in a nonradioactive environment. The mock-up is designed to replicate the areas of the WESF that the capsules will be moved through while transferring them into dry-storage casks.

“Installation of mock-up equipment is a key step for this important project,” said Gary Pyles, RL federal project director. “The ability of workers to practice and get comfortable with the transfer system will help support the safe and efficient movement of these capsules to dry storage when we perform the process in WESF.”

While the mock-up team prepares to test the new equipment this spring, WESF crews are making progress on facility modifications required to support the capsule transfer process.

“This is a complex project that requires design, fabrication and installation of unique equipment, as well as upgrades to the facility,” said Mark Buckmaster, CPCCo project manager. “I’ve been impressed with the entire team’s hard work, creative thinking and commitment to safety.”

From 1974 to 1985, the cesium and strontium recovered from Hanford’s waste storage tanks were placed in stainless steel capsules and stored underwater in cells in the WESF. While the capsules are currently in safe storage in the underwater basin, moving them to dry storage not only eliminates a longer-term risk of a radioactive release in the unlikely event of a loss of water from the basin but also enables the planned deactivation of the aging facility, saving as much as $6 million in annual operating costs.

Check out this animation to learn more about the capsule transfer process.

To receive the latest news and updates about the Office of Environmental Management, submit your e-mail address.