Part 2 of the PV Cells 101 primer, exploring new materials and cell designs that can improve conversion and performance.

Solar Energy Technologies Office

December 3, 2019Welcome back. Part 1 of this primer explains how a solar cell turns sunlight into electricity and why silicon is the semiconductor that usually does it. But silicon cells have a maximum theoretical efficiency of about 32%, so researchers are exploring new materials and cell designs that can improve conversion and performance. Here are the most promising ones:

Layering Up with Multijunction Solar Cells

Some researchers are working to improve cell efficiency by layering multiple different semiconductors to make multijunction solar cells. These cells are essentially semiconductor stacks, as opposed to single-junction cells, which have only one semiconductor. Each layer absorbs a different part of the solar spectrum, making greater use of sunlight than single-junction cells do.

The amount and type of light a semiconductor absorbs is determined by its bandgap, a property that signifies the minimum amount of energy needed to free electrons so the material can conduct electricity. Without this energy, silicon acts like an insulator. Multijunction solar cells can reach record efficiency levels because the light that doesn’t get absorbed by the first semiconductor layer is captured by a layer beneath it. Different layers absorb different parts of the solar spectrum. Once light is absorbed, the energy is converted to electrical current, and less energy is lost since the bandgap is closer to the energy of the absorbed light.

While all solar cells with more than one bandgap are multijunction solar cells, a solar cell with exactly two bandgaps is called a tandem solar cell. Multijunction solar cells that combine semiconductors from columns III and V in the periodic table are called multijunction III-V solar cells.

Multijunction solar cells have demonstrated efficiencies higher than 45%, but they’re costly and difficult to manufacture, so they’re reserved for space exploration. The military is using III-V solar cells in drones, and researchers are exploring other uses for them where power conversion efficiency is key.

The Skinny on Thin-Film Solar Cells

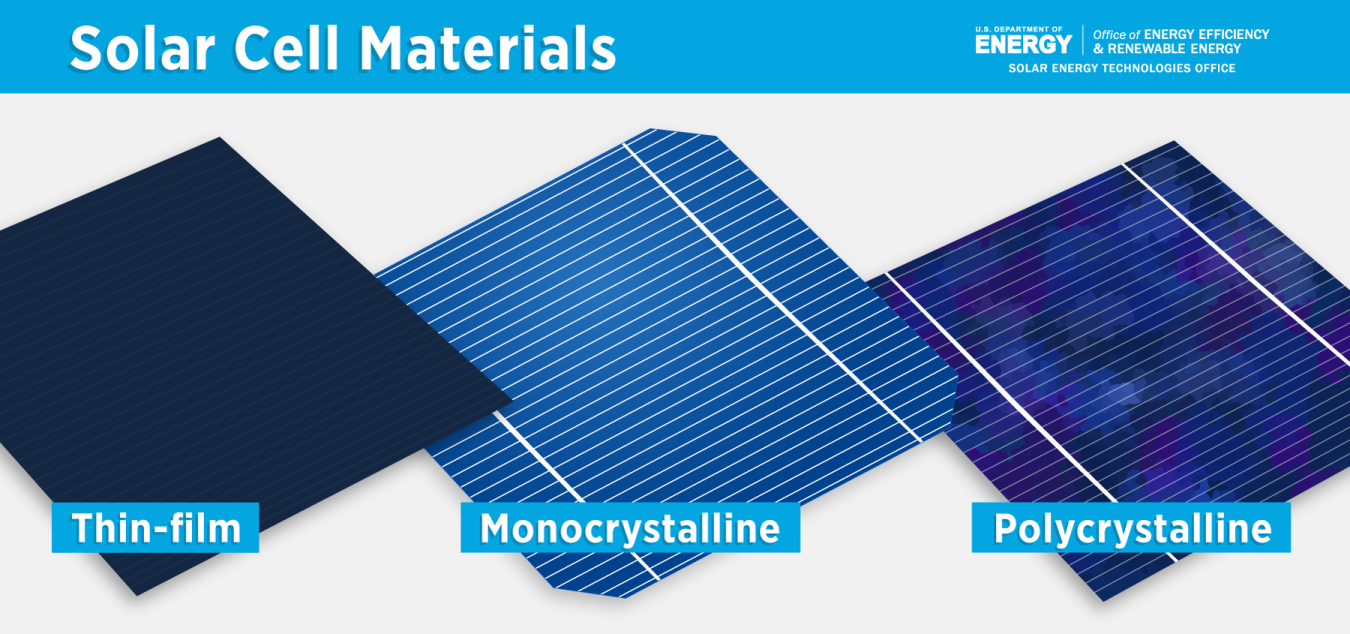

Silicon may be the most common type of solar cell, but thin-film solar cells generally cost less and can be easier to fabricate. Thin films make up 3% to 5% of the global market but are usually less efficient than silicon.

Thin-film solar cells are made by coating a thin layer of a highly absorptive semiconductor material on a sheet of glass, plastic, or metal foil called a substrate rather than creating a crystal wafer. This material can be deposited on flexible surfaces, which keeps costs down and the solar cells versatile. Thin films are typically dark or partially transparent, so the modules look more uniform than the speckled, blue or black crystalline-silicon modules. The record high thin-film cell efficiency is 22.1%, while monocrystalline-silicon cells have reached 25%, and polycrystalline, over 20%.

Three types of thin-film solar cells are on the market:

- cadmium telluride (CdTe)

- copper indium gallium diselenide (CIGS)

- amorphous thin-film silicon (a-Si)

CdTe and CIGS have reached gigawatt-scale production. CdTe is more commercially successful and has reached efficiency levels comparable to crystalline-silicon modules in the lab.

New and Emerging Solar Materials

Researchers are digging deep into thin films. These are the technologies to know about:

Perovskite

Perovskite solar cells are a type of thin-film cell and are named after the eponymous ABX3 crystal structure, with the most studied PV material being methylammonium (MA+) lead (Pb+2) iodide (I-), or MAPbI3. Perovskite cells are built with layers of materials that are printed, coated, or vacuum-deposited onto a substrate. They are typically easy to fabricate and can reach solar conversion efficiencies higher than 20%. In the lab, perovskite solar cell efficiencies have improved faster than any other PV absorber material, from 3% in 2009 to over 24% in 2019. But to be commercially viable, perovskite PV cells have to become more stable and durable enough to survive 20 years outdoors, so researchers are working on that—and developing large-scale, low-cost manufacturing techniques.

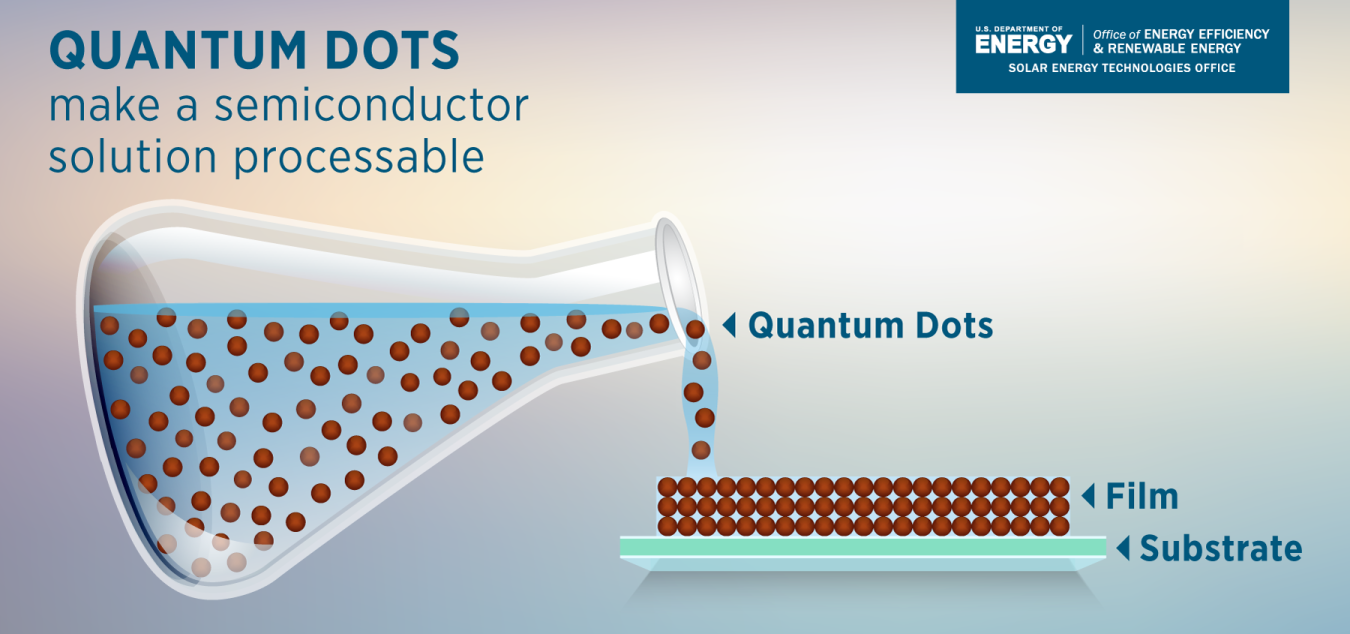

Quantum Dots

Quantum dot solar cells conduct electricity through tiny semiconductor particles a few nanometers wide, called quantum dots. Quantum dots provide a new way to process semiconductors, but it is difficult to create an electrical connection between them, so they’re not very efficient.

But they’re easy to process into solar cells. They can be deposited onto a substrate using a spin-coat method, a spray, or roll-to-roll printers like the ones used to print newspapers. And quantum dots come in various sizes, so their bandgap can be customizable, enabling them to collect light that’s difficult to capture and be paired with other semiconductors, like thin-film perovskite solar cells, to optimize the performance of a multijunction solar cell.

Organic Photovoltaics

Organic photovoltaics (OPV) are lightweight solar cells made with carbon compounds that can be dissolved and solution-processed, which can reduce cell fabrication costs. OPV use organic polymers and molecules that conduct and generate electricity like those in organic light-emitting diode display technologies. And because the organic molecules can be synthesized with tailored properties, OPV devices can be different colors or transparent. This is relevant to the building-integrated PV market, which seeks to replace building-construction materials with PV materials to make windows and facades. Researchers are working to improve device lifetime and efficiency and mitigate the visual effects of aging.

Ultimately, researchers are exploring dozens of types of solar cells, aiming for higher efficiencies, longer lifetimes, and market success. SETO continues to fund innovative PV concepts and experimental designs across a range of materials, building a pipeline of relevant research to support the PV industry.

Want more? Read up on the solar basics and PV research and development funded by SETO.