To establish renewable geothermal energy as a significant contributor to America's future electricity, the Office of Geothermal (OG), formerly the Geothermal Technologies Office (GTO), partners with industry, academia and the national laboratories to discover new geothermal resources; research, develop, and demonstrate innovative technologies; and support commercialization of geothermal power generation and heating & cooling solutions.

Read more about the award-winning advances that are changing the geothermal industry below.

R&D 100 Awards

- 2025: Thermal Energy Storage Systems for Enhancing Thermal Efficiency of Phase Change Materials

- 2024: High Lithium Capacity Sorbents for Direct Lithium Extraction

- 2023: The Renewable Energy Potential (reV) Model

- 2016: E4D-RT: Real-time Four-Dimensional Subsurface Imaging Software

- 2012: NanoSHIELD Coatings

- 2007: Low-Temperature Power Conversion

- 2006: Solid-State High-Temperature Battery

- 2003: Acoustic Telemetry Device

- 2003: The Low Emissions Atmospheric Metering System

- 2002: PPS Coating Technology

- 2001: Silica Recovery from Geothermal Brine

- 2000: Geothermal Well Cement

- 1999: Advanced Direct Contact Condenser

Learn More about OG

2025: Thermal Energy Storage Systems for Enhancing Thermal Efficiency of Phase Change Materials

Phase change materials (PCMs) are effective for storing thermal energy because they can absorb or release significant heat when they switch between phases, such as solid to liquid. They are particularly useful for applications like temperature regulation in buildings. However, a drawback of PCMs is their low thermal conductivity, which means they require a large temperature difference with their heat transfer fluid to change phase quickly, leading to slow phase transition times.

Researchers at Oak Ridge National Laboratory (ORNL) found that adding 5% by weight of anisotropic carbon fibers to PCMs dramatically reduced their melting time from over 8,000 seconds to 1,260 seconds. These fibers enhance heat transfer by increasing the surface area for phase change and acting as pathways for thermal energy. This innovation can lead to more efficient and cost-effective thermal storage systems for various building types.

2024: High Lithium Capacity Sorbents for Direct Lithium Extraction

This sorbent technology selectively extracts lithium from brines, minerals, and recycled batteries, allowing for the uptake of lithium out of brines at least five times as much as current technology. Its benefits include the combination of low cost with high uptake as well as usability at nearly room temperature and over a wide range of pH. Use of these sorbents will contribute to the growth of domestic critical material supply chains and improve the economics of lithium extraction for energy storage applications. GTO, the Advanced Materials and Manufacturing Technologies Office (AMMTO) and other U.S. Department of Energy (DOE) offices funded this research at Oak Ridge National Laboratory (ORNL) through DOE’s Critical Materials Innovation Hub.

2023: The Renewable Energy Potential (reV) Model

The Renewable Energy Potential (reV) visualization model is a detailed spatial-temporal modeling assessment tool that empowers users to calculate renewable energy capacity, generation, and cost while taking into consideration grid infrastructure and land-use characteristics and constraints. Prior to GTO’s work under this initiative, reV’s capabilities were limited to calculations for concentrating solar power, solar photovoltaics, and wind. As part of GTO’s work with NREL on modeling improvements within this initiative, hydrothermal and enhanced geothermal systems (EGS) resources have been implemented in reV, providing a pathway in power modeling that will help demonstrate the value of geothermal power. reV now accounts for geothermal resource estimates, can incorporate resource depth uncertainties, and provides visualization capabilities for resource-infrastructure-development needs.

2016: E4D-RT: Real-time Four-Dimensional Subsurface Imaging Software

The E4D-RT: Real-time Four-Dimensional Subsurface Imaging Software is a technology used to determine the extent of subsurface contamination and what is driving its migration, constructing 3D, time-lapse images of how the subsurface environment changes over time, in real time. E4D-RT is a cost-saving open source solution for imaging many kinds of subsurface studies, including fluid movement in geothermal systems, hydraulic fracturing operations, and even understanding volcanic activity.

2012: NanoSHIELD Coatings

Nano-Super Hard - Inexpensive - Laser Deposited Coatings, or NanoSHIELD Coatings, are created by laser fusing a unique iron-based powder to any type of steel, which forms a strong metallurgical bond that provides wear resistance between two and ten times greater than conventional coatings. This technology can extend the life of costly cutting and manufacturing tools by more than 20%, potentially saving millions of dollars over the course of a project. NanoSHIELD Coatings are designed to protect high-wear tools used for tunnel boring and construction, but also has potential applications for geothermal drilling tools and use by the U.S. Navy. NanoSHIELD Coatings were developed by ORNL in conjunction with Lawrence Livermore National Laboratory, Strategic Analysis Inc., Ozdemir Engineering Inc., Colorado School of Mines and Carpenter Technology Corp.

2007: Low-Temperature Power Conversion

The Low-Temperature Power Conversion device allows commercial energy conversion at lower temperatures, expanding site selection and development options. Previously the lowest temperature for commercial energy conversion was at 208°F; this technology is in use at Chena Hot Springs Resort in Alaska, which at 165°F is the lowest temperature geothermal resource used for commercial energy conversion. This device was developed by UTC Power and United Technologies Research Center as a demonstration partner of DOE, Alaska Energy Authority, Alaska Industrial Development and Export Authority and the Denali Commission.

2006: HTSS10V - Solid-State High-Temperature Battery

Solid-state fluoride batteries consist of nontoxic fluoride and solid components, making them the safest choice for high-temperature drilling operations. The HTSS10V batteries that received this award have a longer shelf life and greater reliability in emergency situations, giving them advantages for battery backup or life support systems during a fire or other emergencies. They can also be transported on commercial aircraft, while lithium sulfuryl chloride batteries can only be transported by ground and must be stored in explosive containers when on a drill rig. The HTSS10V batteries were developed by DOE’s Sandia National Laboratories in conjunction with High Power Battery Systems Company in Nizhny Novgorod, Russia and General Atomics.

2003: Acoustic Telemetry Device

The Acoustic Telemetry Device quickly and reliably transmits data to the surface of a geothermal well using the well-drilling tubing as the data transmission medium and sound waves as the data carrier, in order to improve drilling, increase production, and lower well costs. Its advantages compared to existing techniques are a ten-fold improvement in data rates and no blocking of fluid flow path. This device was developed by DOE's Sandia National Laboratories in cooperation with Extreme Engineering, Ltd.

2003: The Low Emissions Atmospheric Metering Separator

The primary use of the Low Emissions Atmospheric Metering Separator (LEAMS) is to safely contain and clean atmospheric vented steam of polluting solids, liquids, and noxious gases. As of 2003, no atmospheric cyclone separator can perform all these functions as well under a single system. LEAMS was developed by DOE’s Sandia National Laboratories in cooperation with Drill Cool Systems, Inc., and Two-Phase Engineering and Research.

2002: PPS Coating Technology

Polyphenylenesulfide (PPS) is a revolutionary material, developed by Brookhaven National Laboratory and tested by NREL, and won a 2002 R&D 100 award and a Federal Laboratory Consortium Award for Excellence in Technology Transfer. The coating prevents corrosion and inhibits buildup of scale from mineral-rich geothermal brines and caustic industrial fluids, reducing maintenance and capital expenditures. The PPS system can be exposed to production geothermal fluid at 350°F, and has been successfully transferred for commercialization to Curran International, an established company with experience using epoxy and phenolic coatings.

2001: Silica Recovery from Geothermal Brine

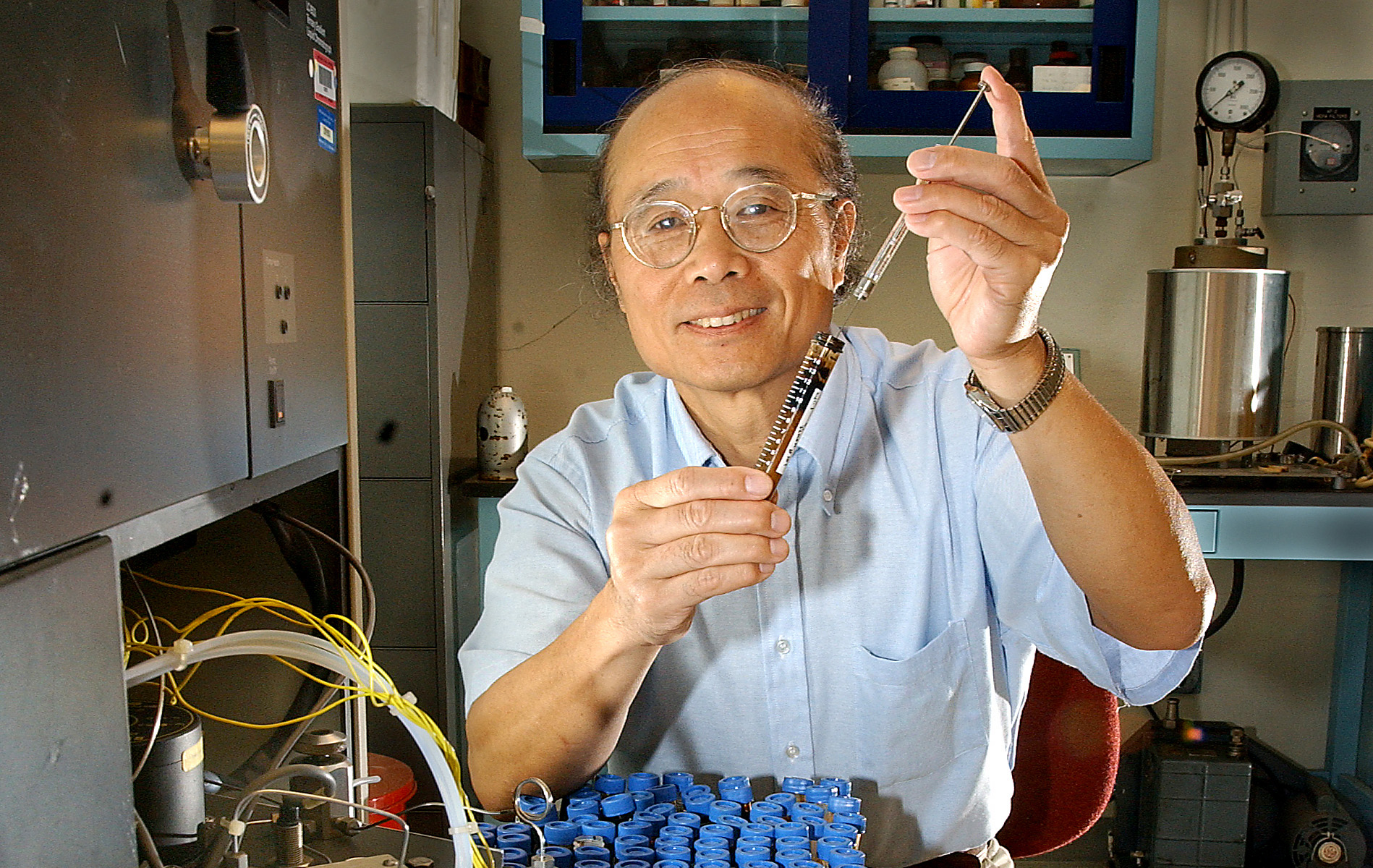

Brookhaven chemist Mow Lin, one of the inventors of the silica recovery process.

Brookhaven National Laboratory and the Caithness Operating Company developed a technology to recover commercial-quality silica from geothermal brine, a byproduct of geothermal energy production. Silica is used widely as a drying agent for products such as salt; a polishing agent for commodities such as toothpaste; as a filler, extender or reinforcer for plastics, paper, paint and rubber; and as a catalyst for refining oil. Retrieving this valuable product from brine, which is generally disposed of as waste, results in lower maintenance costs and in cheaper energy production. The notably pure (~99.9%) recovered silica—much purer than most silica on the market—can be used for new commercial applications, such as in nanoscale materials, sub-micron electronic circuits, and fiber optics.

2000: Geothermal Well Cement

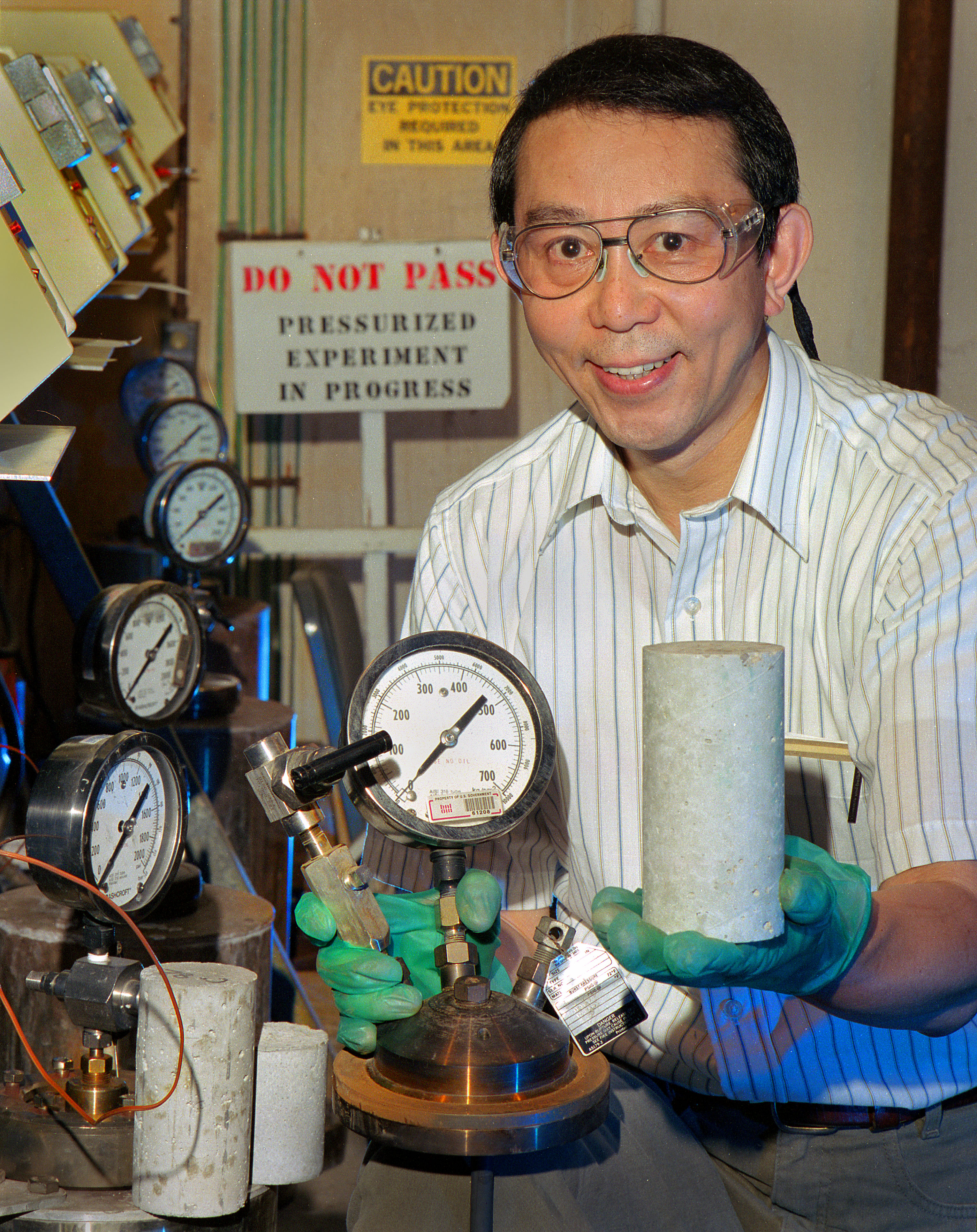

Dr. Toshifumi Sugama of DOE’s Brookhaven National Laboratory developed a high-performance cement that increases useful well life by a factor of 20 or more. Typically, the harsh, hostile environment of a geothermal well rapidly degrades conventional cements that are supposed to keep the well intact. This new cement means savings of $150,000 per well per year over a 20-year lifetime of the well.

Pictured right: Dr. Sugama wins R&D 100 Award.

1999: Advanced Direct Contact Condenser

The advanced direct-contact condenser (ADCC) uses sophisticated geometric shapes to provide optimal surface area for condensing spent steam. The technology has been employed at Unit #11 at The Geysers, where it has improved production efficiency by 5%, has cut the chemical cost for emission abatement in half, and total power generation potential by 17%. ADCC also can be used for fossil-fuel power plants and for food processing or any other industrial process in which steam is condensed. In addition to the R&D 100 Award, the ADCC also won a Federal Laboratory Consortium Award for Excellence in Technology Transfer.