Many common products developed from petrochemicals can be supplemented or developed with biomass feedstocks. These include nutritional supplements, plastic building blocks, water bottles, detergents, carbon fiber, and cosmetics and perfume.

Up to 16% of U.S. crude oil consumption is used to make petrochemicals and products—such as plastics for industrial and consumer goods, fertilizers, and lubricants—contributing an added value of $812 billion to the U.S. economy.1 Many products derived from petrochemicals could be supplemented with biomass-derived materials. In some cases, the unique properties of biomass may provide advantages for efficiently producing new biomass-derived chemicals. BETO is supporting research and development of these bio-advantaged products.

STRATEGIES FOR PRODUCING BIO-BASED CHEMICALS AND PRODUCTS

There are many types of strategies that BETO can invest in to encourage bioproduct production. These strategies include investing in:

- Products that enable and support existing biorefineries (e.g., biogas conversion, acid pretreated lignin)

- Products that enable the operation of future biorefineries based on current research projections (e.g., alkaline lignin)

- Products that are manufactured in stand-alone facilities intended to help de-risk biorefineries through lessons learned (e.g., products that enable the construction of supply systems/depots).

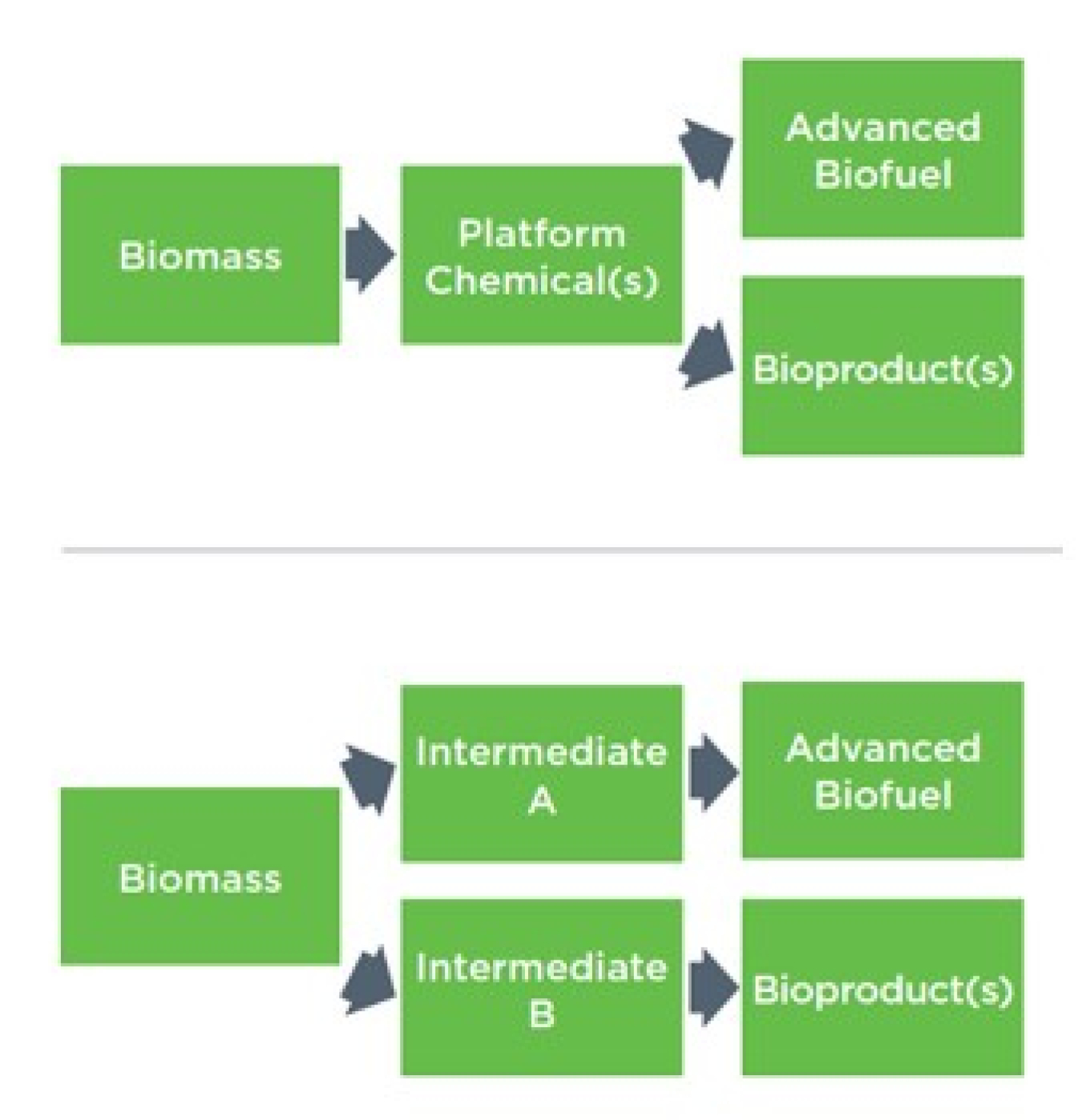

Different routes for producing bioproducts.

Enabling a product slate from a biorefinery, especially by valorizing materials that are currently waste products, can substantially reduce risks associated with early biofuel plants and biorefineries. Bioproduct production can also significantly de-risk the upstream infrastructure and processes needed for biofuels by providing an increased economic incentive for the construction of pioneer biorefineries.

This was an empty link: LessonsLessons Learned from Bioproduct Development Applied to Biofuels

The production of bioproducts relies on much of the same feedstocks, infrastructure, feedstock commoditization, and technologies that are central to biofuels production. The difference between producing a biofuel or a bioproduct may be in the upgrading of the deconstructed biomass intermediate. For example, cellulosic sugars are an intermediate for manufacturing either biofuel or bioproducts. Due to their similarities, the knowledge gained from producing bioproducts can be readily transferred to biofuels or be a means to develop platform technologies that lead to fuels. Furthermore, major challenges associated with biomass feedstocks and any lessons learned will be useful—regardless of whether the final products are biofuels or bioproducts.

Once technologies are proven for bioproduct applications, they could greatly improve biofuel production. For example, there are biomass pretreatment technologies that are considered prohibitively expensive for biofuels and are not investigated. However, the pretreatment technologies could potentially produce cleaner pretreated feedstocks for conversion and reduce conversion and separations costs. Bioproducts provide a venue to explore high-risk, high-reward solutions that could be applicable to biofuels.

Publications

- Carbon Fiber from Biomass

- Chemicals from Biomass: A Market Assessment of Bioproducts with Near-Term Potential

- Bioproducts to Enable Biofuels Workshop Summary Report

- Top Value-Added Chemicals from Biomass: Volume II—Results of Screening for Potential Candidates from Biorefinery Lignin

- Top Value-Added Chemicals from Biomass: Volume I—Results of Screening for Potential Candidates from Sugars and Synthesis Gas

Other Resources/Quick Links

- BETO Bioproducts Basics

- Infographic: Bioproducts, Grown and Made in America

- Workshop on Moving beyond Drop-In Replacements: Performance Advantaged Biobased Chemicals

- Bioproducts to Enable Biofuels Workshop Bioproducts to Enable Biofuels Workshop

- Energy Department Announces $11.3 Million for MEGA-BIO: Bioproducts to Enable Biofuels

- Recent Activity on Bioproducts that Enable Biofuels in the Bioenergy Technologies Office

- Bioenergy Technologies Incubator 2

- BETO Partner Makes the 2016 CNBC Disruptor Companies List

- Lygos Wins Innovation Award for Cutting-Edge Progress Toward Biobased Chemical Production

- Integrating the Production of Biofuels and Bioproducts

- Plant Products a Growing Research Area

- BETO Project Improves Production of Renewable Chemical from Cellulosic Feedstocks

-------------------------------------------------

1Bloomberg New Energy Finance, EIA, American Chemical Council. Bioproducts to Enable Biofuels Workshop Summary Report (U.S. Department of Energy, 2015), https://www.energy.gov/sites/prod/files/2015/12/f27/bioproducts_to_enable_biofuels_workshop_report.pdf