Bioprose Blog: The Bioenergy Technologies Office and National Renewable Energy Laboratory developed a novel process that uses biomass gasification.

November 27, 2018

Author: Zia Abdullah, Laboratory Program Manager, National Renewable Energy Laboratory

Read Zia's bio ►

Meet the other bloggers ►

Return to Bioprose blog ►

BIOPROSE BLOG

Over the past five years, the market share for premium gasoline in the United States has increased from 9% to 12%.1 To help meet the growing demand for high-octane gasoline, the Bioenergy Technologies Office and the National Renewable Energy Laboratory (NREL) developed a novel process that uses biomass gasification—converting solid biomass into gas under high temperatures. This high-octane gasoline blendstock is low in aromatic compounds, which are molecules that have regulated limits in gasoline, and greatly reduces technology uncertainty.

The Process

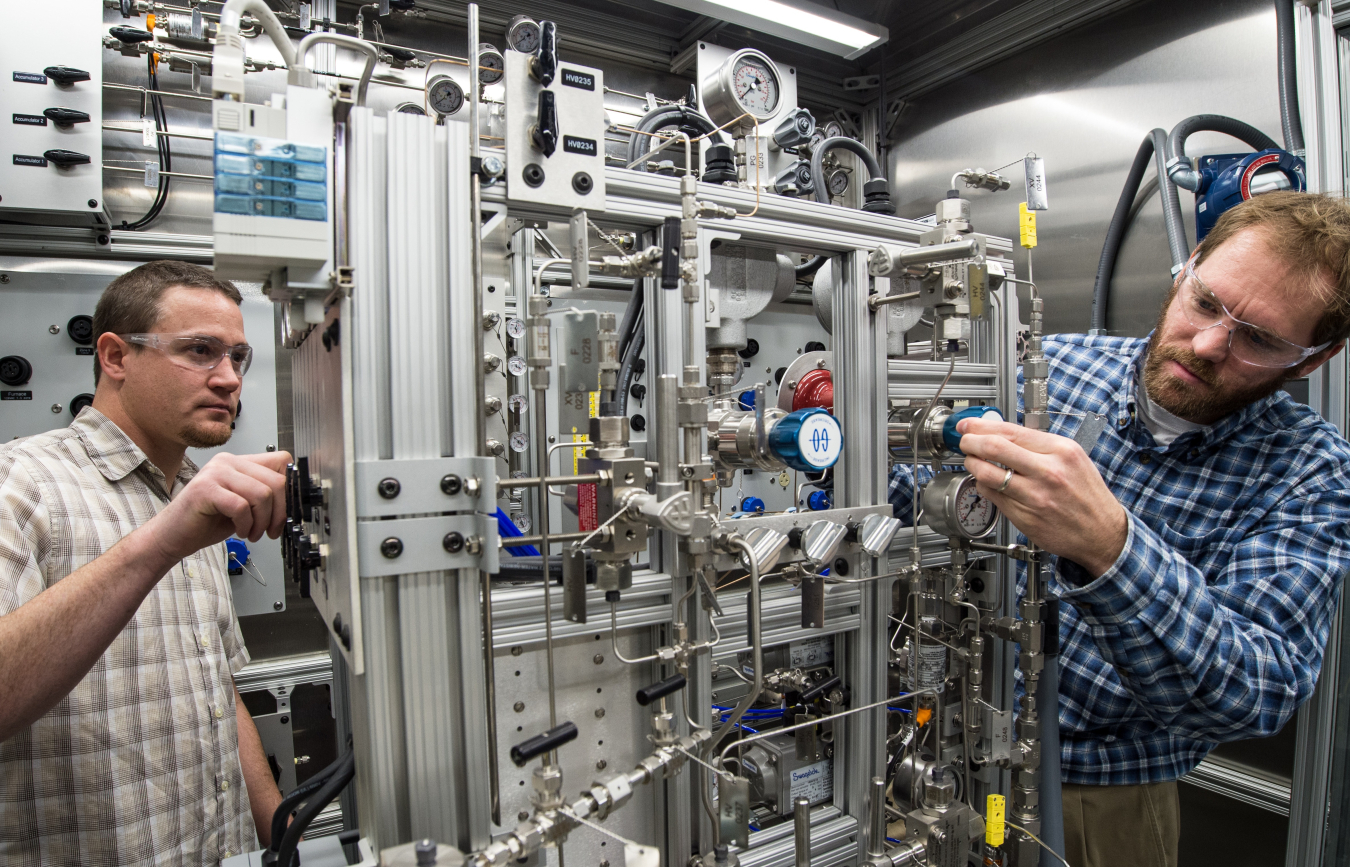

To make this new blendstock, NREL’s indirect liquefaction team first converts biomass into synthesis gas (syngas) using a gasifier, a reformer, heat, and catalysts. The team, led by Dr. Dan Ruddy and Dr. Jesse Hensley, has optimized the efficiency of this process, resulting in a high yield of syngas per kilogram of biomass fed to the system. Next, in a single step, the researchers use the syngas to produce an oxygenated intermediate—dimethyl ether—which is ultimately converted into a high-octane gasoline blendstock.

The Success

The NREL team has achieved more than 300 hours of continuous operation for their conversion process using a proprietary, but commercially relevant catalyst. To put this into perspective, past conversion runs were limited to just 24 hours. This success provides a path for industry to scale up this novel breakthrough technology in the near term. In fact, NREL and BETO have already established collaborations for further scale-up and integration at industrial sites. For example, Enerkem, a Canadian producer of chemicals and clean transportation fuels, is working with NREL under a U.S. Department of Energy Technology Commercialization Fund grant to scale-up production of high-octane biofuels from biomass-derived dimethyl ether.

NREL’s research has helped inform the efforts of the U.S. Department of Energy’s Co-Optimization of Fuels and Engines initiative, which identifies bio-derived blendstocks that can enable greater efficiency and performance in advanced gasoline engines. Increased demand for high-octane gasoline will create a new market for blendstocks that—due to their desirable fuel properties and low aromatic content—can be blended with traditional petroleum refinery streams. NREL’s technology can enable industry to serve this market, creating new agricultural and manufacturing jobs, increasing market penetration for biofuels, and advancing U.S. energy security.

[1] *“The New Economics of Octane – What Drives the Cost of Octane and Why Octane Costs Have Risen Since 2012.” OPIS, MathPro Inc., and THiggins Energy. 2017. https://www.opisnet.com/product/news/exclusive-study-new-economics-octane/.

Bioprose Blog

Dr. Zia Abdullah

Dr. Zia Abdullah is laboratory program manager for the National Laboratory of the Rockies' (NLR) Bioenergy Technologies Office program.

Zia has extensive experience and accomplishments in thermochemically and biochemically converting biomass to fuels and chemicals. His experience includes more than 25 years of industrial research and development in biomass conversion, as well as problem solving, new product development, business development, and project management.

Prior to joining NLR, Zia was chief technology officer at Versa Renewables LLC, where he developed and commercialized biomass pyrolysis and biopolyol technologies. Before Versa, Zia served as one of the Battelle Memorial Institute’s 11 fellows, leading the development of technology and commercial application for fuels, chemicals, and materials from the thermochemical and biochemical conversion of biomass. Prior to working at Battelle, Zia was a research advisor (fellow) at Weyerhaeuser Company, where he worked on challenges related to manufacturing and biomass valorization.

Meet our other bloggers ►

Return to Bioprose blog ►