PNNL research elevates possibility of co-processing and looks to reduce deployment risks

April 21, 2022

Author: Dr. Asanga Padmaperuma

Senior Research Chemist in the Energy Processes and Materials Division at Pacific Northwest National Laboratory

Read Asanga's bio ►

Meet the other bloggers ►

Return to Bioprose blog ►

Upgrading bio-oils with petroleum feedstocks at existing refineries—known as “co-processing”—could offer a fast pathway for lowering the carbon footprint of today’s transportation fuels. With equipment and infrastructure already in place, more than 100 refineries across the country are equipped to integrate bio-oil into their processes. But just where might companies insert bio-oils into existing refinery systems like fluid catalytic crackers and hydrotreaters? If successful, just how much of that renewable or “green” carbon makes it into final fuel products?

In this three-part blog series, the National Renewable Energy Laboratory (NREL), Pacific Northwest National Laboratory (PNNL), and Los Alamos National Laboratory (LANL) offer insights into these pressing co-processing questions—and others—amid the push to dramatically expand the production of climate-friendly fuels. Read part 1 and part 3.

Converting low-carbon biomass and wastes, like crop waste, food waste, and algae, into high-value fuels and products can serve as a low-carbon equivalent to fossil-based gasoline, jet, and diesel fuel. What could be more ideal for reducing carbon intensity?

Renewable resources and wastes from plant matter can be converted to bio-oils. Wet wastes, including sewage sludge, can be transformed into biocrude. These so-called biogenic sources of carbon are similar to petroleum feedstocks in that they both need to be refined to produce high-quality fuels, such as those used in transportation.

Upgrading bio-oil and biocrude into fuels by blending them with petroleum crude in existing refineries will produce low-carbon fuels at a lower cost than building standalone biorefineries. It would also mean that biofuels can be introduced to the market faster to support growing demand. But researchers at Pacific Northwest National Laboratory (PNNL) wanted to know how biogenic carbon feedstocks will affect refinery operations, including chemical reactions, catalysts, and final product quality.

The U.S. Department of Energy’s national laboratories are determined to give refinery operators and policy makers the information they need to approve co-processing biocrude and bio-oil in petroleum refineries.

Putting Biocrude and Bio-Oils Through the Refinery Paces

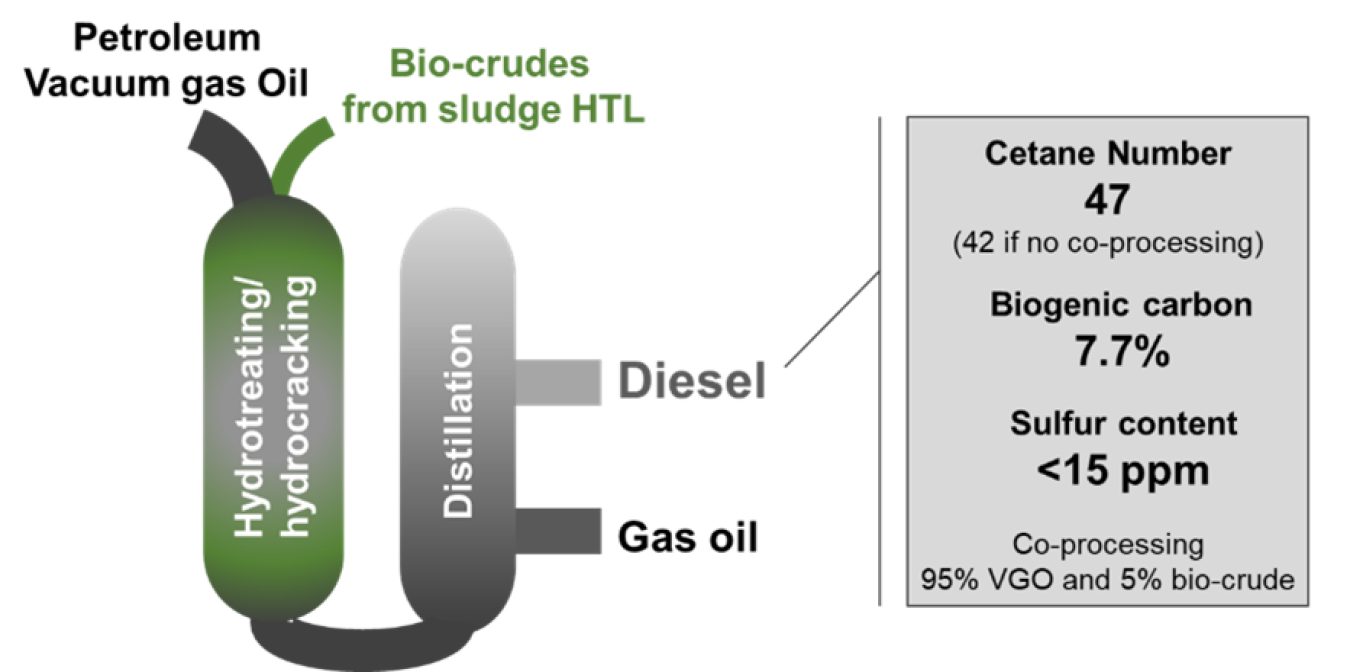

PNNL is known for advancing hydrothermal liquefaction (HTL)—a technique that uses high heat and pressure to produce biocrude from wet wastes, such as sewage sludge, that results in biocrude similar to petroleum crude. Both need upgrading to remove sulfur, nitrogen, and oxygen before they can produce transportation fuels. Hydrotreating and hydrocracking are common upgrading methods used in refineries, and both processes are ideal for co-processing a blend of biocrudes and petroleum to produce lower-carbon jet fuels, low-sulfur marine fuels and diesel.

A PNNL research team led by Huamin Wang is testing HTL biocrude from sewage and bio-oils from other low-carbon sources like wood scraps. The team is running the biocrude together with petroleum refinery streams using laboratory-scale hydrotreating and hydrocracking processes that mimic refinery processing. The blends tested ranged from 2 – 20% bio-derived feedstocks.

PNNL is working with a leading developer of refinery catalysts and a refinery that currently co-processes animal fats to ensure the test configuration and catalysts are realistic. Researchers are determining the impact of co-processing on chemistry, catalyst stability, and fuel quality and investigating how much of the carbon from biomass incorporates into the upgraded fuel products.

To date, studies demonstrate that more than 90% of the biogenic carbon found in feedstocks can be incorporated into high-quality fractions of fuel. This means that biocrude effectively converts to diesel or other products suitable for transportation and aviation fuel. Researchers also found that co-processing biocrude and petroleum crude actually results in improved diesel quality when using certain feedstocks, such as sewage sludge.

Co-processing biocrudes with petroleum in a hydrotreater produces biogenic, carbon-containing diesel with a higher cetane number. The higher cetane number is an indicator of the combustion speed or quality of diesel fuel. (Image courtesy of Huamin Wang | Pacific Northwest National Laboratory)

Slower Reactions—A Problem with a Solution

Researchers also discovered that biocrudes slow down chemical reactions necessary for petroleum feedstocks. Refineries typically must operate at a certain reaction rate to make sure the resulting fuel products are within required specifications. Biocrudes from sewage sludge naturally have high levels of nitrogen species, which bind more strongly to the catalyst used in refinery hydrotreating processes designed to remove impurities. These nitrogen species cause reactions to slow, resulting in products with a higher sulfur content than straight petroleum products.

In addition, researchers found that the catalyst needed for hydrotreating biocrude degrades faster, reducing its lifetime. This is due to certain foulants in biocrudes, such as minerals and reactive compounds.

Researchers are working to mitigate the nitrogen and catalyst degradation issues by pretreating biocrudes to reduce foulants, adding a hydrotreating step to lower nitrogen content, and improving an inexpensive guard bed to protect valuable hydrotreating catalysts.

There are also small ways to modify refinery catalysts and operations and adjust chemical reactions so that co-processing will have a minimum impact on operations. PNNL is gaining insight into those methods by working with refiners and catalyst developers.

A PNNL researcher operates a bench-scale hydrotreater for co-processing study. (Photo courtesy of Andrea Starr, Pacific Northwest National Laboratory)

Predicting Refinery Output Based on Bio Feedstocks

A deep understanding of how problematic nitrogen-containing species in biocrude react, including how fast they react (reaction kinetics), is key to predicting co-processing performance. PNNL researchers measure these reactions and incorporate the data into existing computer models used by petroleum refineries. Currently, these commercial software models aren’t applicable to biocrude feedstocks; therefore, they can’t predict the interaction between biocrude and petroleum intermediates or the potential impact of co-processing on reactor design and operation. However, revised models that use PNNL data will provide the predictive analysis needed by refinery operators.

Cost and Value

Leveraging the infrastructure in existing refineries reduces the costs associated with upgrading bio-oils and biocrudes. PNNL conducted a techno-economic analysis to evaluate the value of co-processing for biocrude refiners. The analysis suggests co-processing biocrudes in petroleum refineries can reduce biofuel upgrading costs by up to 45%.

But is there an economic benefit to the petroleum refineries? Petroleum refineries profit if they’re able to purchase a biogenic feedstock with a price lower than its breakeven point. Researchers evaluated the breakeven point of using biocrudes in a five percent blend at a petroleum refinery, considering both positive and negative operating impacts and using a crude oil price of $60 per barrel. Their analysis shows that the breakeven point without carbon credits is just slightly lower than the purchase cost of biocrude with the current state of technology. With ongoing development of co-processing and biocrude production technologies and the inclusion of carbon credits, co-processing biomass feedstocks with petroleum may soon create economic value to petroleum refiners.

Refining Research

PNNL will continue working with industrial partners to evaluate co-processing in full-scale refinery operations. Understanding the impacts and benefits of co-processing at a larger scale and under longer operation times will provide the data needed to eliminate barriers for industry adoption of co-processing. The team is also expanding its research to other renewable feedstocks and reaction operations.

With these studies, PNNL continues to focus on recycling carbon that is otherwise a waste stream or a liability, and producing fuels and products that enhance energy security and reduce environmental impacts.

Dr. Asanga Padmaperuma

Dr. Asanga Padmaperuma is a Senior Research Chemist in the Energy Processes and Materials Division at Pacific Northwest National Laboratory. He serves as the Laboratory Relationship Manager for the Department of Energy's Bioenergy Technologies Office, which has oversight of research in renewable use of marine, terrestrial, and waste biomass for fuels and chemicals via thermal, biological, and electrocatalytic conversion.

Dr. Padmaperuma also serves as the Technical Leader for the Chemical Conversion team in PNNL's Chemical and Biological Processing Group. Prior to his current assignment, his research focus was on thermochemical, low-temperature catalytic, and electrochemical production of value-added chemicals and fuels from bio-based and waste sources. He also conducted research in design and development of functional molecules for organic electronics and liquid scintillators for radiation detection.

Dr. Padmaperuma completed his B.Sc. in Chemistry at the University of Colombo (Sri Lanka) and obtained his Ph.D. in Organic Polymer Chemistry at the University of Southern California's Loker Hydrocarbon Research Institute. He is a named inventor on several granted patents as well as an author of more than 50 journal articles, book chapters, and public technical reports.

Meet our other bloggers ►

Return to Bioprose blog ►