Researchers from across the U.S. and around the world use computing power to solve problems and discover new information through modeling, design...

Advanced Manufacturing & Industrial Decarbonization

August 17, 2017

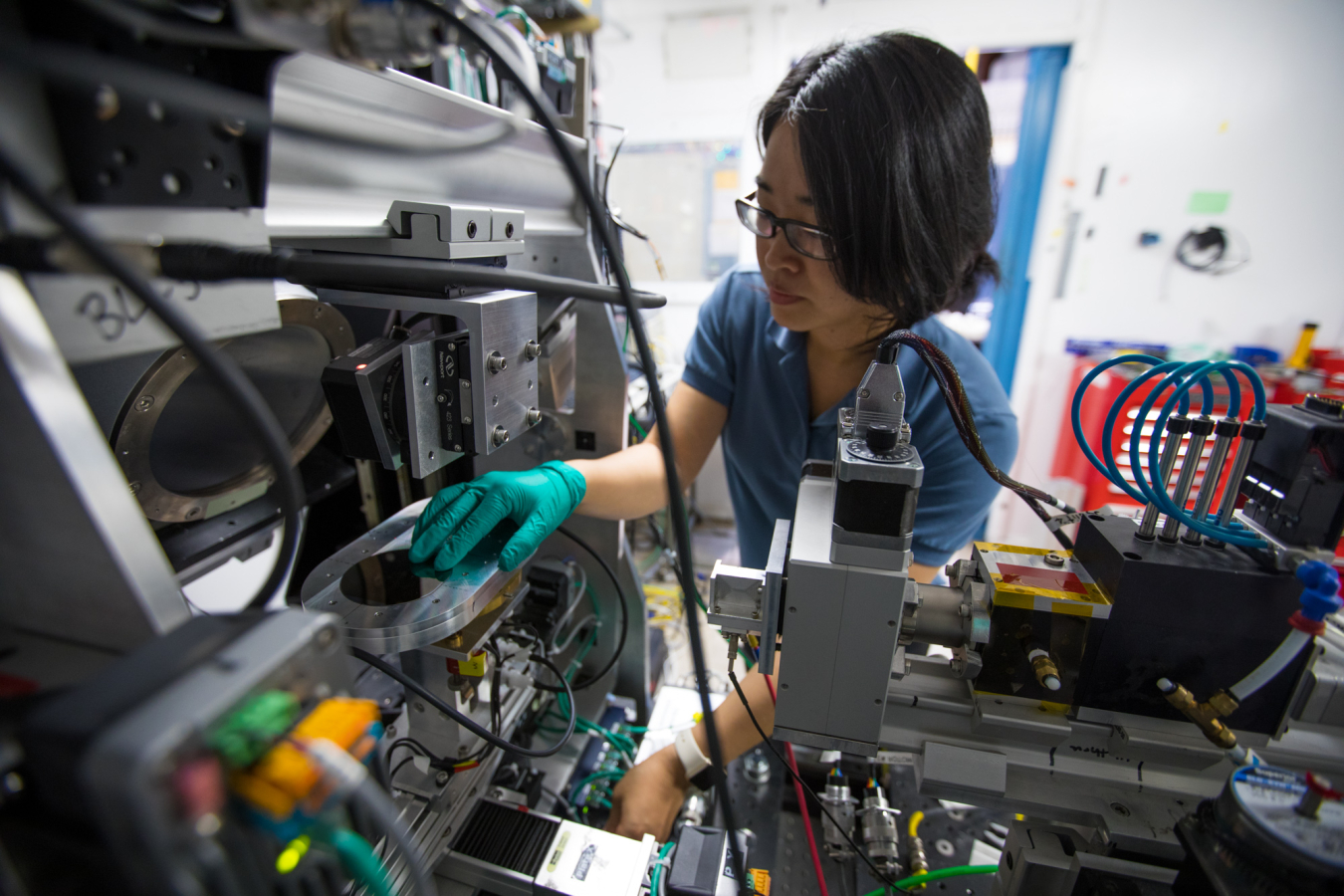

Dr. Fang Ren, a postdoctoral fellow at SLAC, loads a combinatorial library on the high throughput data collector at the Stanford Synchrotron Radiation Lightsource at SLAC. (Photo Courtesy Dawn Harmer/SLAC National Accelerator Laboratory)

Researchers from across the U.S. and around the world use computing power to solve problems and discover new information through modeling, design, and analysis of technical challenges. One field that is making significant advances is the modeling of new materials. Computational materials science is a great way to quickly sift through all possible compositions of materials to identify potential new compositions that could be used for a variety of applications, but since designs are based on computer models there is still scientific uncertainty about bringing new materials from conception to reality. The next challenge is how to apply the same acceleration factor that computing brought to the design phase to the materials synthesis and characterization phase – or the actual production and validation of new materials.

This is the very challenge that brought together researchers at the Department of Energy’s SLAC National Accelerator Laboratory and Citrine Informatics in a new two-year public-private partnership funded by the Energy Department’s Advanced Manufacturing Office (AMO). In the first of a two-phase approach, SLAC and Citrine are conducting research to answer basic science and technology questions about materials. SLAC is home to the Stanford Synchrotron Radiation Lightsource (SSRL), which produces extremely bright x-rays as a resource for researchers to study our world at the atomic and molecular level. Citrine Informatics is a platform that combines artificial intelligence with the world’s largest materials database to use patterns in data. Through a combined use of systems, SSRL collects the data and Citrine uses machine technology to analyze data to find patterns. The benefit of machine learning is that users don’t need to know why something would work, only that it does work. Citrine’s platform uses known chemical properties and relationships to predict reactions that can be used in new processes. Researchers can collect data about materials in real time and use it to more rapidly find new materials.

It’s the kind of cutting-edge, basic science R&D our national laboratories are known for. The research isn’t about searching for materials for any one specific application – it is about developing a methodology for discovering new materials that can be applied across any kind of manufacturing.

Dr. Mark Hartney, Chief Technical Officer and Applied Energy Programs Division Director at SLAC, describes the team’s research as, “Hunting for secret recipes that give you the best results.” Think of a farmer sampling soil in different parts of his or her fields to find the perfect soil composition for their crops. Or think of searching for oil – you try multiple points until you find the spot you’re looking for. What SLAC and Citrine are doing is similar, just on a molecular and atomic scale.

The next phase will include selecting concrete examples to demonstrate and validate the methodology. SLAC and Citrine plan to work with metallic glasses and explore ways to develop a high strength material that could be molded similar to plastic. Another example is optimizing the synthesis process for nanoparticle catalysts. In the future, their work could be applied at other DOE user facilities and used by other public-private consortia like the Department of Energy’s Critical Materials Institute. This kind of public-private partnership is crucial to lowering technological barriers and driving innovation, resulting in economic growth, jobs, and energy security.