Scientists found two competing mechanisms that contribute to the deformation of nanosheet materials used in cutting-edge computer components.

June 9, 2025The Science

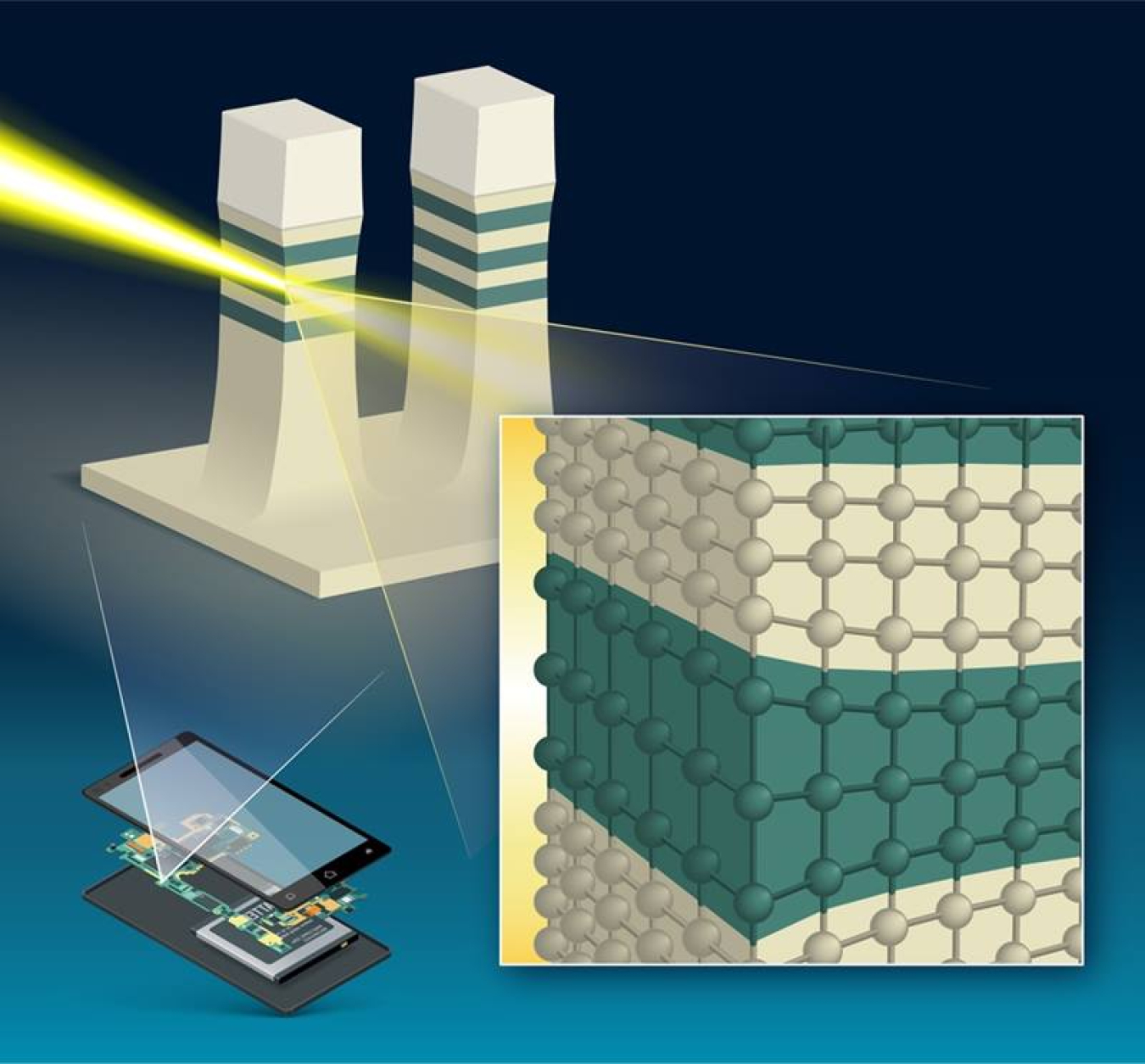

As electronics become smaller, researchers are designing new devices using novel nanoscale materials. These materials have new structures, such as ultra-thin layered “nanosheets.” Understanding the inner details of these tiny devices helps researchers use them in microelectronics. However, the devices’ small size makes it very difficult to examine them in a way that doesn’t destroy their initial structure. In this study, scientists used an X-ray beam with a diameter of just 12 nanometers (12 billionths of a meter) to “see” the details of the nanosheets’ structures without damaging them. The experiments revealed two competing mechanisms that contribute to how deformations occur in these nanosheets.

The Impact

Consumers want electronics that are ever smaller and faster. But the fabrication methods industry and researchers use to create tiny, high-power electronics are complex and can cause the nanostructures to have unwanted defects and deformations. Understanding these inner details—and doing so in a way that doesn’t cause further damage—is essential to determining how to use nanostructures in real-world applications. This study provides a non-destructive method for studying materials that yields insights into the structure of these devices at the nanoscale. It also opens a new avenue for developing novel nanoscale structures for electronics applications.

Summary

Nanosheets are used in tiny next-generation electronic components called Gate-All-Around Field Effect Transistors (GAAFETs). These components form the basis of computer microprocessors at the heart of smartphones and computers. In this study, a team of researchers from IBM collaborated with scientists from the National Synchrotron Light Source II (NSLS-II), a Department of Energy Office of Science user facility at Brookhaven National Laboratory, to map the deformations within nanosheets. The researchers investigated these structures using the Hard X-ray Nanoprobe (HXN) beamline at the NSLS-II light source.

By exploiting the brilliant source of X-rays and the resolving power provided by a nanofocusing optics setup called a multilayer Laue lens, the researchers were able to identify two competing mechanisms at different length scales that contribute to the deformation. The first, which is long-range and previously known, is due to the mismatch of lattice constant between the different elements and a relaxation effect near edges. The second, a much shorter-range effect, is associated with the layering itself and is dominant within a length scale of the nanosheet thickness from the edge. These new insights could help researchers predict essential performance parameters of future devices, such as the carrier mobility.

Contact

Hanfei Yan

National Synchrotron Light Source II, Brookhaven National Laboratory

hyan@bnl.gov

Conal E. Murray

IBM T.J. Watson Research Center

conal@us.ibm.com

Funding

This research used resources at the National Synchrotron Light Source II, a Department of Energy Office of Science user facility.

Publications

Murray, C.E., et al., Mapping of the mechanical response in Si/SiGe nanosheet device geometries. Nature Communications Engineering 1, 11 (2022) DOI: 10.1038/s44172-022-00011-w]