Using DNA scaffolding, scientists developed a universal method for producing a wide variety of functional, 3D metallic and semiconductor nanostructures

December 18, 2025The Science

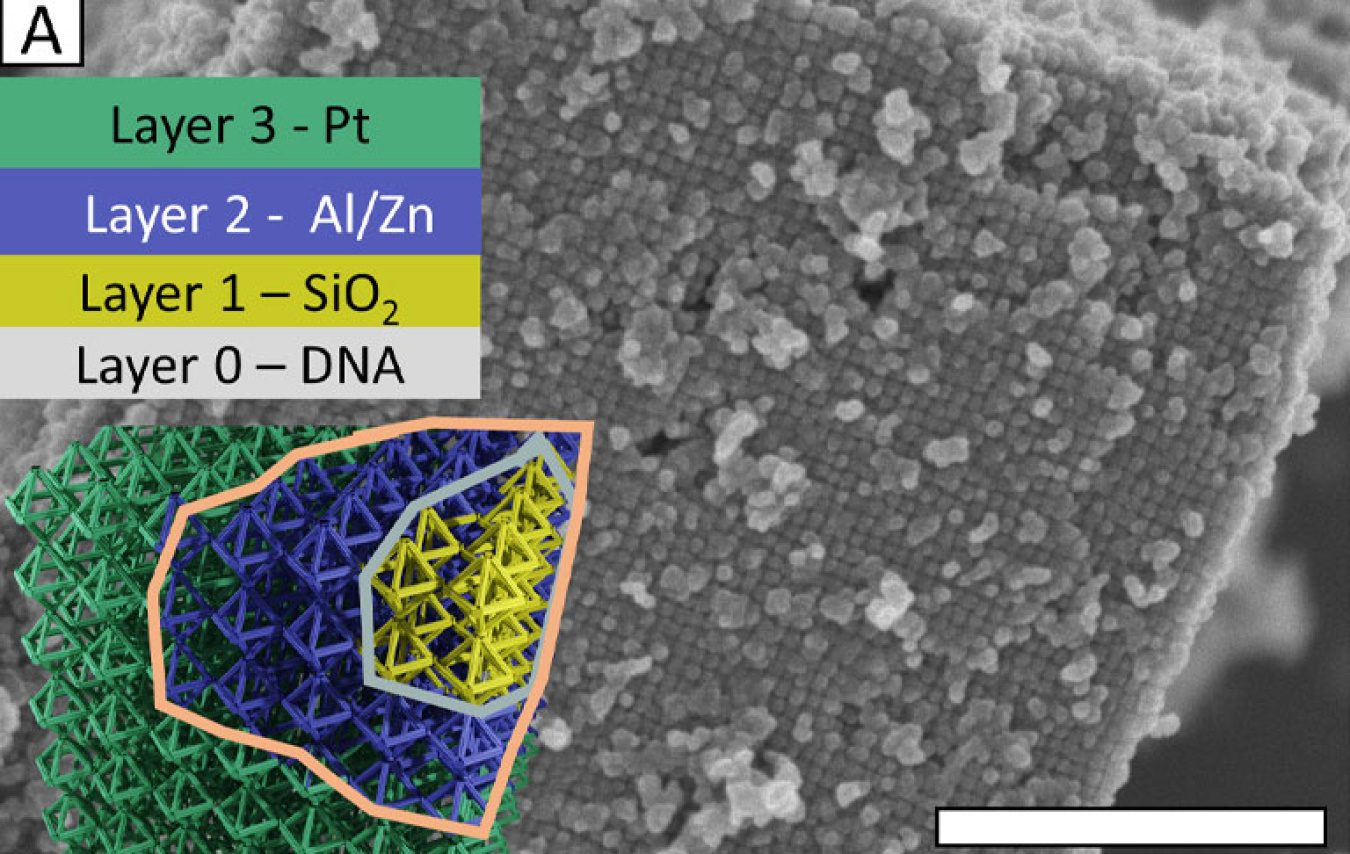

For scientists to access and control inorganic materials’ unique properties, they need to be able to control these materials’ three-dimensional (3D) nanoarchitectures. Scientists can use DNA to guide nanoparticles to assemble into larger structures. Researchers used this technique to establish a new way to design 3D frameworks made of inorganic materials. Using DNA as a template, the team fabricated diverse classes of inorganic frameworks. These frameworks were made of metal, metal oxide, and semiconductor materials as well as their combinations.

The Impact

This work establishes a new bottom-up nanofabrication platform. This platform is specifically helpful for generating designed nanomaterials for uses in energy conversion, light manipulation, and microelectronics. These nanomaterials could be useful in applications ranging from batteries to information processing. The method offers a level of advanced 3D nanofabrication that no other current technology can offer.

Summary

There has been increasing interest in fabricating three-dimensional (3D) structured inorganic materials at nanoscales. There is no current methodology that scientists can use to generate complexly structured 3D inorganic materials of different classes with control of material composition and volumetric architecture at the nanoscale. In this work, scientists at Columbia University and the Department of Energy’s Brookhaven National Laboratory developed a platform approach for generating inorganic nanostructured frameworks for diverse material types by using self-assembled ordered 3D DNA scaffolds as templates. Previous research has reported a broad range of DNA architectures based on the intrinsic programmability of DNA. Some work has even integrated DNA with nanoparticles. However, it was difficult to transition this technology to applications due to the functional and robustness limitations of DNA structures. The new study resolves this problem by establishing a method for “converting” DNA nanostructures into inorganic replicas from diverse types of inorganic materials.

The inorganic “conversion” used two complementary techniques: liquid- and vapor- phase infiltrations. The vapor-phase infiltration technique bonds a precursor chemical, in vapor form, to a nanoscale lattice. This approach allows the chemical to penetrate beyond the surface and deep into the material’s structure. The liquid-phase infiltration technique is similar, except that it uses a liquid form of precursors. By coupling the advances in DNA nanotechnology with templating, the approach opens the possibility of generating prescribed 3D inorganic nanomaterials of different and mixed types. This approach promises to address many challenges in electronics, mechanics, photonics, battery, and catalysis by offering a flexible bottom-up nanomaterial generation platform.

Contact

Oleg Gang

Columbia University

Center for Functional Nanomaterials (CFN), Brookhaven National Laboratory

og2226@columbia.edu

Funding

This research used Materials Synthesis and Characterization and Electron Microscopy Facilities of the Center for Functional Nanomaterials (CFN), as well as 11-BM complex matter scattering (CMS) and 3-ID HXN beamlines of the National Synchrotron Light Source II (NSLS-II), both of which are DOE Office of Science User Facilities at Brookhaven National Laboratory. The DNA assembly work was supported by the DOE Office of Basic Energy Sciences; the inorganic templating was supported by the U.S. Department of Defense, Army Research Office; and the on-chip material integration was supported by the Keck Foundation.

Publications

Aaron Michelson et al. Three-dimensional nanoscale metal, metal oxide, and semiconductor frameworks through DNA-programmable assembly and templating. Sci. Adv. 10, eadl0604(2024). [DOI: 10.1126/sciadv.adl0604]

Related Links

Hacking DNA to Make Next-Gen Materials, Brookhaven National Laboratory news release.