A fast, automated, and high-throughput pipeline is improving the speed of plant engineering

Biological and Environmental Research

August 26, 2025The Science

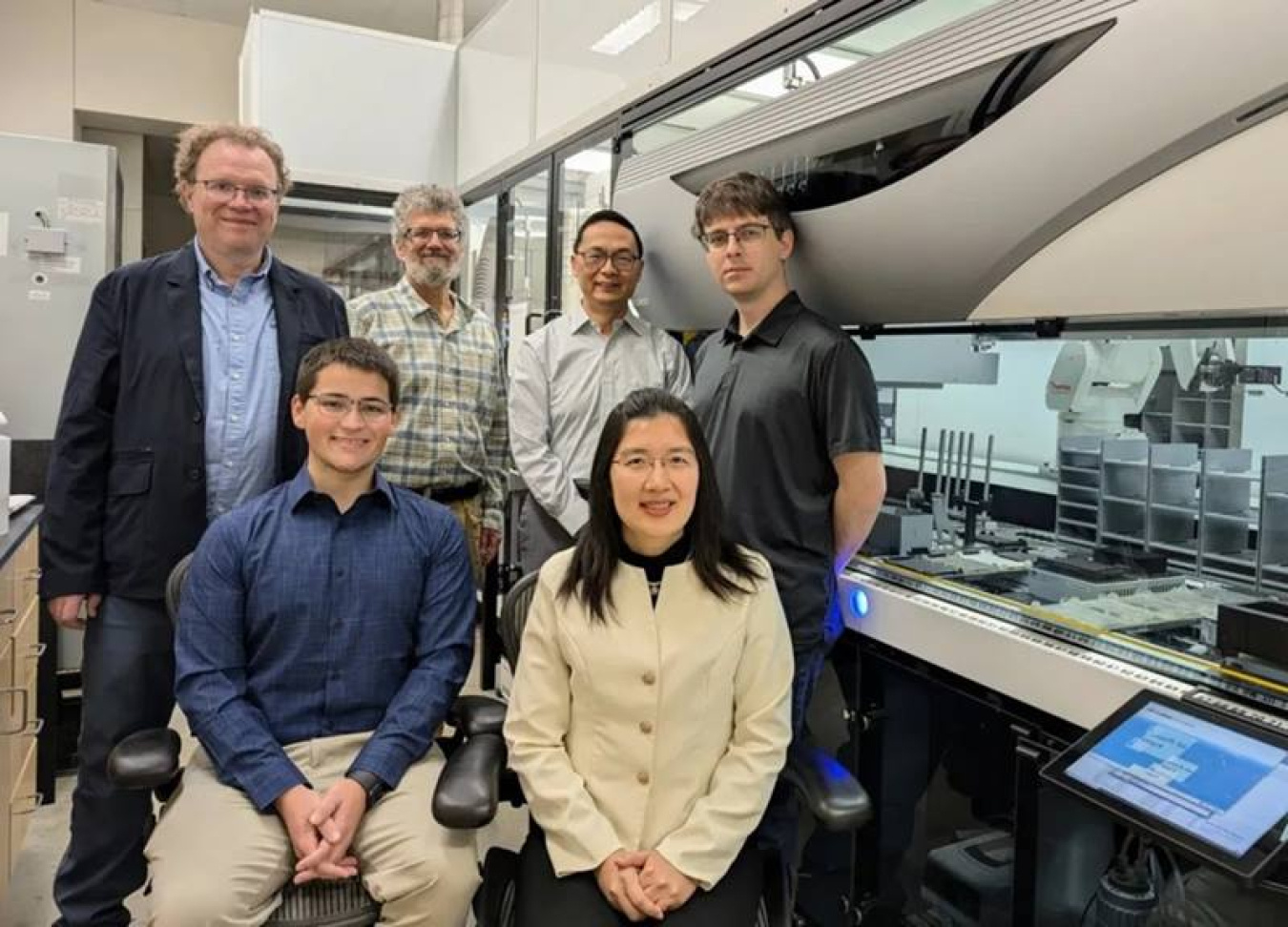

A team of researchers at the Center for Advanced Bioenergy and Bioproducts Innovation (CABBI) have found a way to use robots to accelerate plant engineering. Researchers deployed a biofoundry – a laboratory that integrates robotics, computer-aided design, and information science. With this tool, they made genetically engineered plants that produced more oil in plant cells and even whole plants.

This fast, automated, scalable, high-throughput pipeline is called FAST-PB. Scientists can scale it up to improve the speed and productivity of synthetic plant biology, genome editing, and metabolic engineering. This advance will help scientists quickly improve valuable plant traits.

The Impact

The large-scale production of biofuels depends on improving energy sources based on plants. By automating key steps, this research accelerates the development of better bioenergy crops. These crops will be able to produce more oil, be more resilient, and be more efficient. This work paves the way for more resilient and scalable biofuel production. It ultimately supports the transition to a more bio-based economy, which would add value to agriculture, support rural economies, and increase domestic energy production.

Summary

In a major breakthrough, a team at the Center for Advanced Bioenergy and Bioproducts Innovation (CABBI) used robots to accelerate plant engineering, boost oil production in plant cells, and make whole plants with higher lipid content. Researchers created three automated processes with multiple robots in a biofoundry – a laboratory integrating robotics, computer-aided design, and informatics. It speeds up the design and testing of genetic changes in plants. They combined the biofoundry with single-cell metabolomics to engineer plant genomes and characterize cellular effects, which has never been done before. This fast, automated, scalable, high-throughput pipeline for plant bioengineering, or FAST-PB, can be scaled up to improve the speed and productivity of synthetic plant biology, genome editing, and metabolic engineering. This advance will help scientists quickly improve valuable plant traits, such as increasing oil production and optimizing photosynthesis.

More broadly, the work contributes to the development of scalable, cost-effective, and automated strategies for optimizing bioenergy crops. By reducing the time, labor, and costs associated with plant transformation and metabolic engineering, this research accelerates the development of bioengineered crops with improved energy storage, resilience, and yield.

Contact

Matthew Hudson

Center for Advanced Bioenergy and Bioproducts Innovation

University of Illinois Urbana-Champaign

mhudson@illinois.edu

Funding

The work was supported by the Center for Advanced Bioenergy and Bioproducts Innovation, a U.S. Department of Energy (DOE) Bioenergy Research Center supported by the Biological and Environmental Research program in the Office of Science.

Publications

Dong, J., et al. Enhancing lipid production in plant cells through automated, high-throughput genome editing and phenotyping. The Plant Cell 37, 2 (2025). [DOI: 10.1093/plcell/koaf026]

Related Links

CABBI team deploys robotic lab to revolutionize plant bioengineering, University of Illinois Urbana-Champaign News