Everything you need to know about uranium enrichment for nuclear reactor fuel.

November 4, 2025Before natural uranium can be used as fuel in most nuclear power plants, it needs to undergo enrichment in order to sustain a nuclear chain reaction.

Natural uranium mined from the earth contains more than 99 percent uranium-238 (U-238), an isotope that decays slowly over billions of years.

The other 0.7 percent is uranium-235 (U-235) — a naturally occurring material which can sustain a fission chain reaction, releasing large amounts of energy.

Enrichment raises the concentration of U-235 in uranium fuel to make it more likely to sustain a reaction in commercial nuclear reactors.

Uranium Enrichment Processes

There are many approaches to enrichment. The three main types of enrichment technologies include gaseous diffusion, gas centrifuge, and laser enrichment, although other methods are currently in development.

Gaseous Diffusion Enrichment

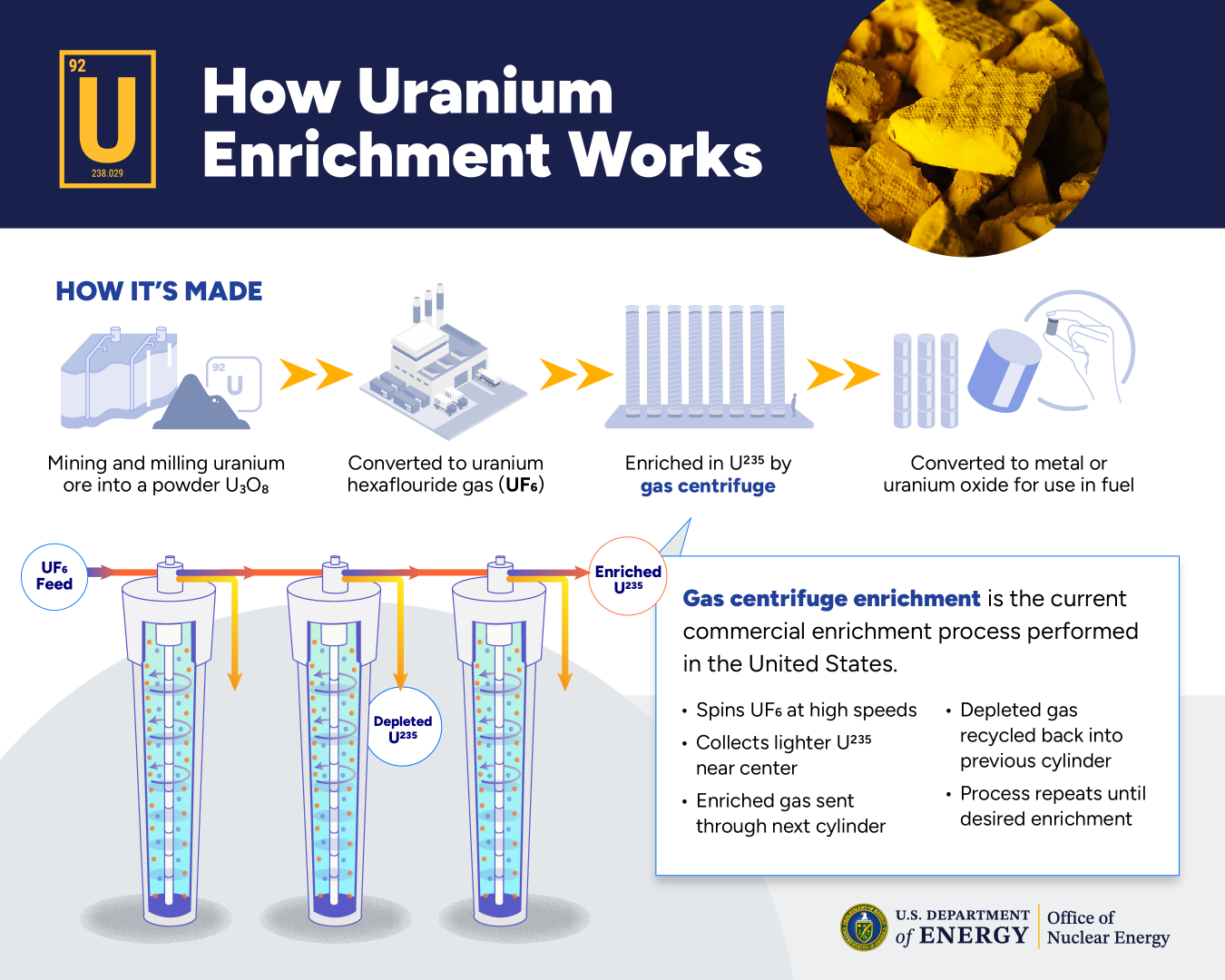

Both gaseous diffusion and gas centrifuge enrichment use uranium hexafluoride (UF6) gas, produced through a chemical process called “conversion.”

Gaseous diffusion was the first large-scale process used to enrich uranium in the United States. It was devised in the 1940s and used through the Cold War era before giving way to more efficient methods in the early 2000s.

Within a gaseous diffusion unit, UF6 gas was pumped through filters called barriers or porous membranes. The lighter UF6 molecules, containing more of the U-235 isotope, passed through these filters more quickly than those containing more U-238.

After passing through hundreds of stages, the uranium finally contained U-235 at the desired concentration.

The enriched UF6 was later “deconverted” back to solid form for fuel fabrication.

The process required tremendous amounts of electricity and was eventually replaced by improved gas centrifuge technology.

Gas Centrifuge Enrichment

The uranium enrichment process commercially used in the United States today is called “gas centrifuge enrichment.”

At a uranium enrichment plant, UF6 gas is fed into gas centrifuge cylinders and rotated at high speeds.

U-238 is one percent heavier than U-235, so the spinning motion causes the heavier isotope to move to the outer edge of the cylinder.

In our current fuel cycle, the process separates gaseous UF6 into two streams — essentially an enriched and a depleted stream. These streams are connected into large cascades to reach the desired enrichment level.

After enrichment is complete, the enriched UF6 is shipped to a fuel fabrication facility, where it is chemically processed to form uranium dioxide powder, then compressed into fuel pellets.

Currently, there are two gas centrifuge production plants licensed in the U.S. to enrich uranium — URENCO USA’s facility in Eunice, New Mexico, and Centrus Energy in Piketon, Ohio.

Gas centrifuge technology can also be used to produce medical isotopes, which are important for medical treatments, diagnoses, and research.

Laser Enrichment

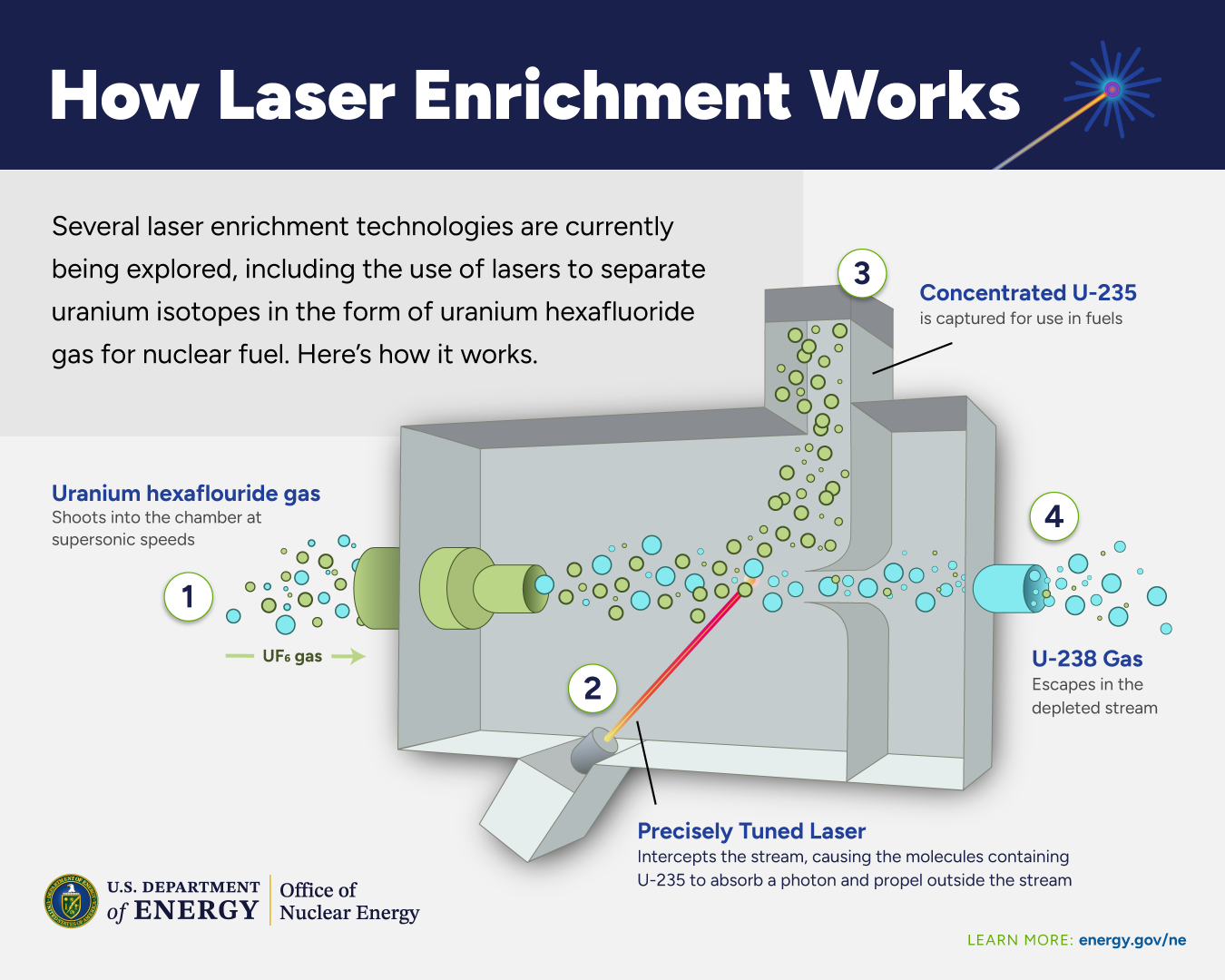

A new enrichment process called laser separation, or laser enrichment, is currently in development by several commercial companies. Laser enrichment technology could potentially offer a more efficient and cost-effective method of uranium enrichment compared to gas centrifuge enrichment and gaseous diffusion.

There are two main types of laser enrichment: atomic and molecular.

Atomic laser isotope separation uses finely tuned lasers to ionize and capture U-235 from a vapor of pure uranium metal (not UF6), leaving behind a stream depleted of U-235.

Molecular laser isotope separation follows a similar approach but instead uses lasers to excite the molecule.

This technology has not yet been utilized at the commercial level as part of the nuclear fuel cycle, and no laser separation uranium enrichment plants currently operate in the United States.

Laser enrichment technology could also be used in medical isotope production.

Uranium Enrichment Levels

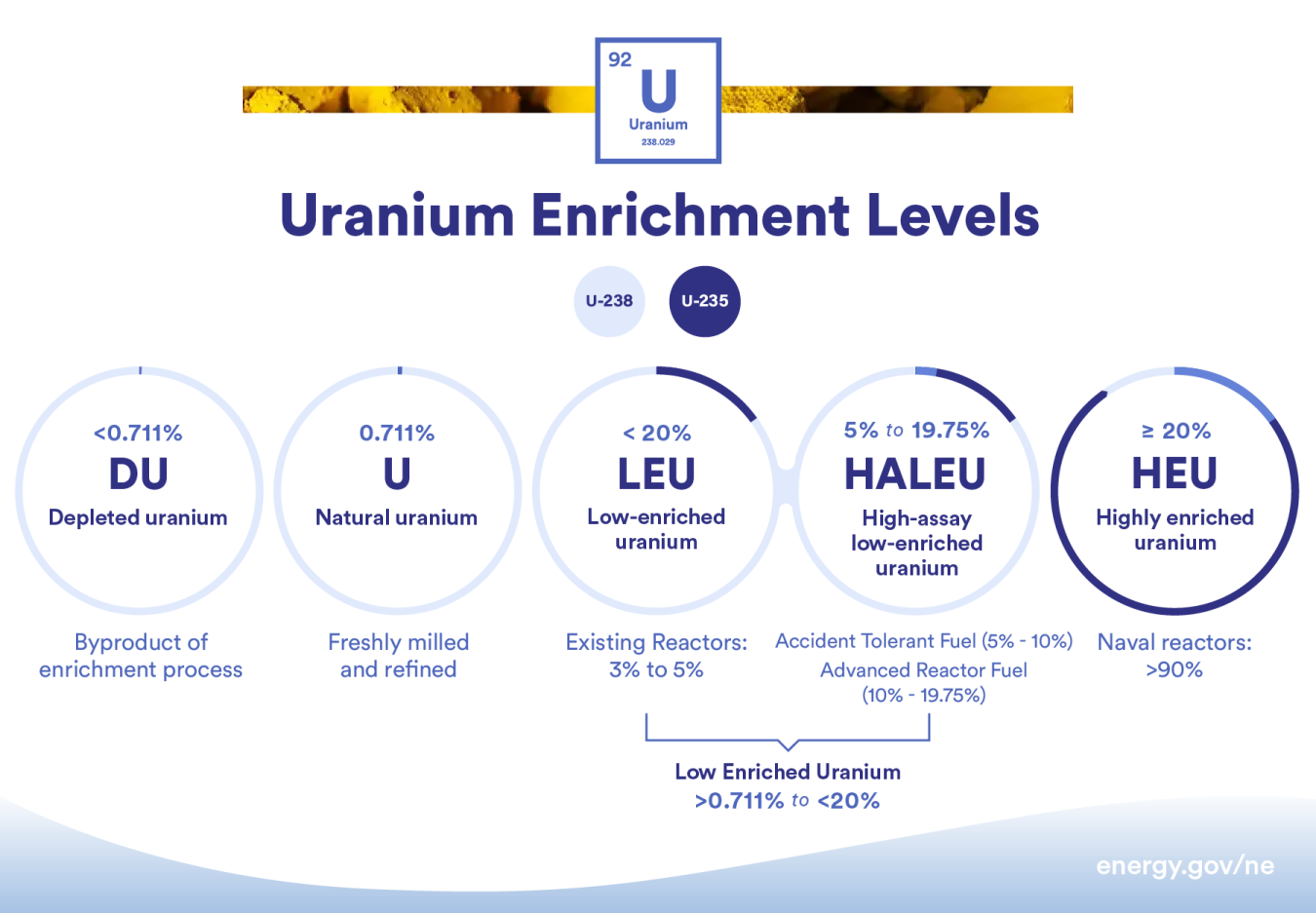

Uranium is commonly enriched to a range of different levels. The level of enrichment required depends on the reactor design and the needs of the nuclear power plant operator.

Low Enriched Uranium (LEU) is enriched uranium containing less than 20 percent U-235. Nearly all commercial nuclear reactor fuel currently uses LEU enriched to between 3 and 5 percent U-235.

Low Enriched Uranium Plus (LEU+) fuel is being developed to enhance the performance of the nation’s current fleet of light water reactors. LEU+ is enriched between 5 and 10 percent U-235 and could allow reactors to operate for a longer period before needing to be refueled and boost performance.

High-Assay Low-Enriched Uranium (HALEU) is enriched between the 5% and 19.75% range, which includes LEU+. Most advanced reactors in development are designed for use with HALEU, to achieve smaller designs, longer operating cycles, and increased efficiencies over current technologies. While HALEU isn’t widely available to reactor developers yet, DOE is working to support next-generation nuclear technologies and access to HALEU through the HALEU Availability Program.

Highly Enriched Uranium (HEU) is more than 20 percent U-235. It’s used primarily in naval propulsion reactors, nuclear weapons, and some research reactors.

Enrichment Capacity in the United States

Russia currently supplies approximately 44% of global uranium enrichment services and 20-30% of enriched uranium product used in the United States and Europe.

The U.S. Department of Energy (DOE) is working to expand domestic commercial LEU enrichment and HALEU enrichment capabilities to meet the fuel needs of our nation’s fleet of nuclear reactors.

President Trump’s executive orders called for an increase in mining, enrichment, conversion and deconversion capabilities — and even recycling and reprocessing of spent nuclear fuel — with assistance from DOE-supported nuclear industry consortia.

In 2025, DOE is expected to finalize task orders with selected companies to participate in its low-enriched uranium and high-assay low-enriched uranium capacity building programs. The finalized contracts would allow the companies to start enriching and storing material that can be fabricated into fuel for current and future reactors.

This $3.4 billion effort supports a larger strategy to expand domestic production capacity for LEU and HALEU, which will help transition the United States away from Russian-sourced fuel and further the President’s energy dominance agenda.

Learn more about DOE’s ongoing work to build out a domestic uranium fuel supply chain.