Drawing from an innovative technology, the Oak Ridge Office of Environmental Management and contractor UCOR have achieved a breakthrough set to eliminate a complex legacy waste stored at Oak Ridge National Laboratory for the past 50 years. August 12, 2025

Office of Environmental Management

August 12, 2025Oak Ridge Office of Environmental Management (OREM) and UCOR officials visit the Waste Control Specialists facility in Andrews, Texas, to observe a demonstration project that has created a disposal path for reactive metals. UCOR President and CEO Ken Rueter is pictured second from left, OREM Manager Erik Olds is third from left, and UCOR Waste Management and Operations Director Sean Dunagan is fourth from left.

OAK RIDGE, Tenn. – Drawing from an innovative technology, the Oak Ridge Office of Environmental Management (OREM) and contractor UCOR have achieved a breakthrough set to eliminate a complex legacy waste stored at Oak Ridge National Laboratory for the past 50 years.

In recent weeks, U.S. Department of Energy (DOE) Office of Environmental Management (EM) crews shipped the first of several large aluminum and steel containers filled with highly reactive metals — called sodium shields — for use in a demonstration of the technology that provides a pathway for their permanent disposal. The demonstration was completed successfully.

The sodium shields were used in the 1960s and 1970s to pioneer radiation shielding research. The largest of them is about 5 feet high and weighs over 30,000 pounds.

Oak Ridge Office of Environmental Management crews packed and shipped the first of the sodium shields to the Waste Control Specialists facility in Andrews, Texas, for vitrification in recent weeks.

This breakthrough effort was made possible through EM's Technology Operations Office funding the demonstration project to ship and process the first sodium shield.

The first challenge involved shipping the sodium shields from Oak Ridge. That challenge was solved after OREM and UCOR obtained a special permit from the U.S. Department of Transportation, thanks to a months-long effort by subject matter experts to conduct an extensive safety analysis and develop a packaging strategy for the waste.

The second challenge was determining if the selected technology could successfully process the reactive metals from the sodium shields. OREM and UCOR employed Veolia Nuclear Solutions’ patented GeoMelt technology at the Waste Control Specialists facility in Andrews, Texas. The vitrification process proved successful by converting the metals into a stable glass form for safe, permanent disposal.

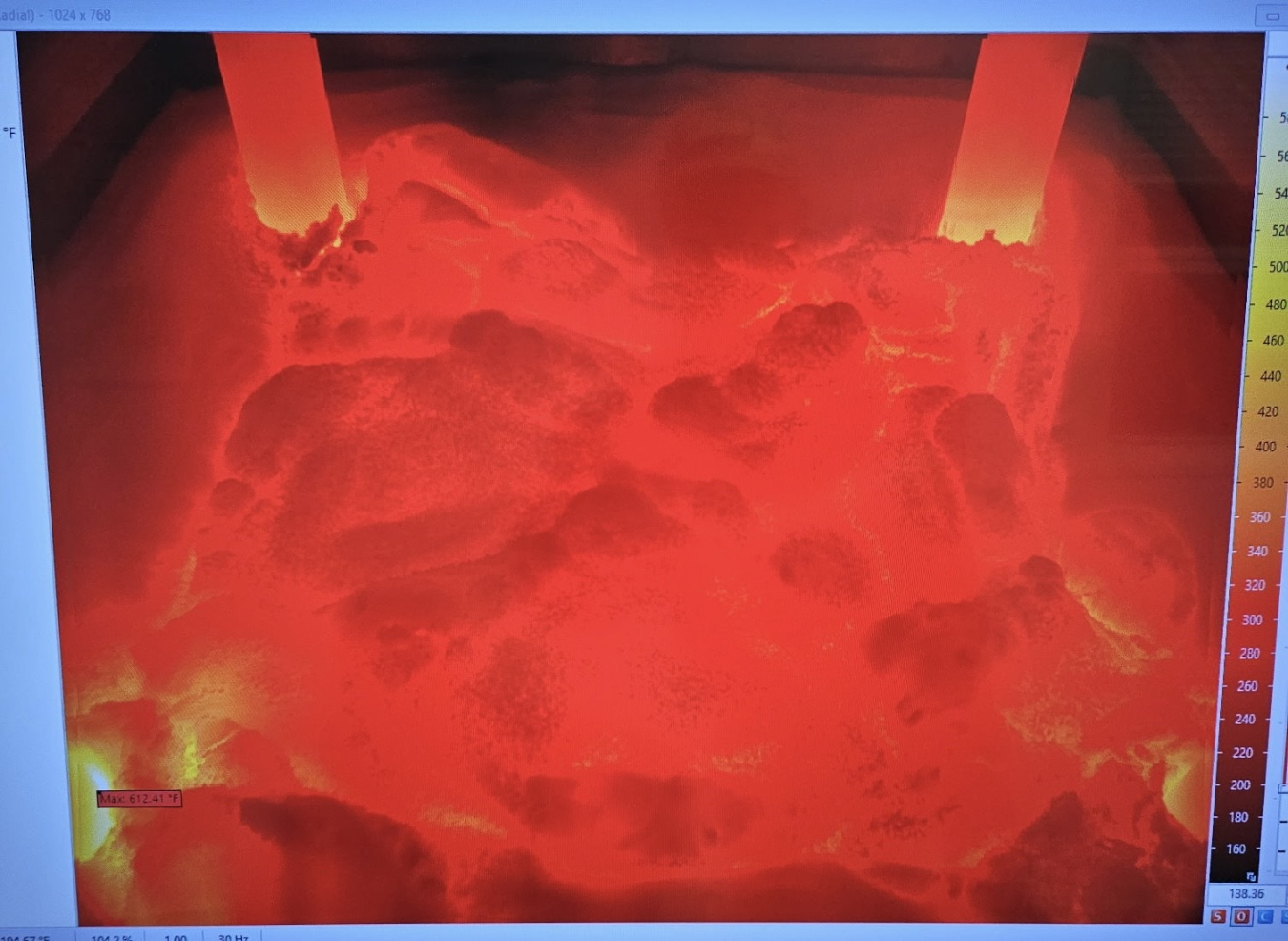

In a demonstration at the Waste Control Specialists facility in Andrews, Texas, a vitrification process successfully converted the first of the sodium shields stored at Oak Ridge National Laboratory into stable glass for disposal.

The GeoMelt technology heats the sodium shields to more than 2,700 degrees Fahrenheit, turning the reactive metal into a stable glass form for safe, permanent disposal through a process known as vitrification.

Sodium metal presents unique hazards because it is unstable and can be highly reactive when mixed with water. The GeoMelt process is unique because it does not use any liquid to support treatment and avoids generating other challenging waste steams during the treatment process. After treatment, the vitrified waste form no longer exhibits reactive or ignitable characteristics.

"This represents a significant advancement in our ability to address legacy materials that have posed unique storage and handling challenges for half a century," said Clint Mori, manager of UCOR's difficult waste streams. "A successful sodium shield vitrification demonstration opens the door to a safe and compliant disposal pathway for this challenge."

The Veolia demonstration project represents a crucial step in addressing challenging legacy waste streams from America's nuclear research history, establishing a potential template for handling similar reactive metal waste streams across the DOE complex.

-Contributor: Mike Butler

To receive the latest news and updates about the Office of Environmental Management, submit your e-mail address.