Fast reactors use fast-moving neutrons to make better use of nuclear fuel and offer several advantages over water-cooled commercial reactors.

August 20, 2025Fast reactors use fast-moving neutrons to make better use of nuclear fuel.

They can operate on recycled fuel from other reactors to drastically improve the fuel efficiency, waste reduction, and performance of nuclear power plants.

Around 20 fast reactors have been built worldwide since the 1950s, including several systems in the United States that were used for testing, demonstrations, and even commercial operation.

New designs are now under development to meet the surging demands for affordable, reliable, and secure power.

Fast Neutron Reactors

The main job of a nuclear reactor is to house and control nuclear fission — a physical process in which atoms split and release energy.

Most reactors in operation today use water to cool the reactor and transfer heat from the fuel for energy production.

The water is also used to slow down or moderate the fast-moving neutrons released during fission to maintain the chain reaction in low-enriched fuels.

Fast reactors operate differently.

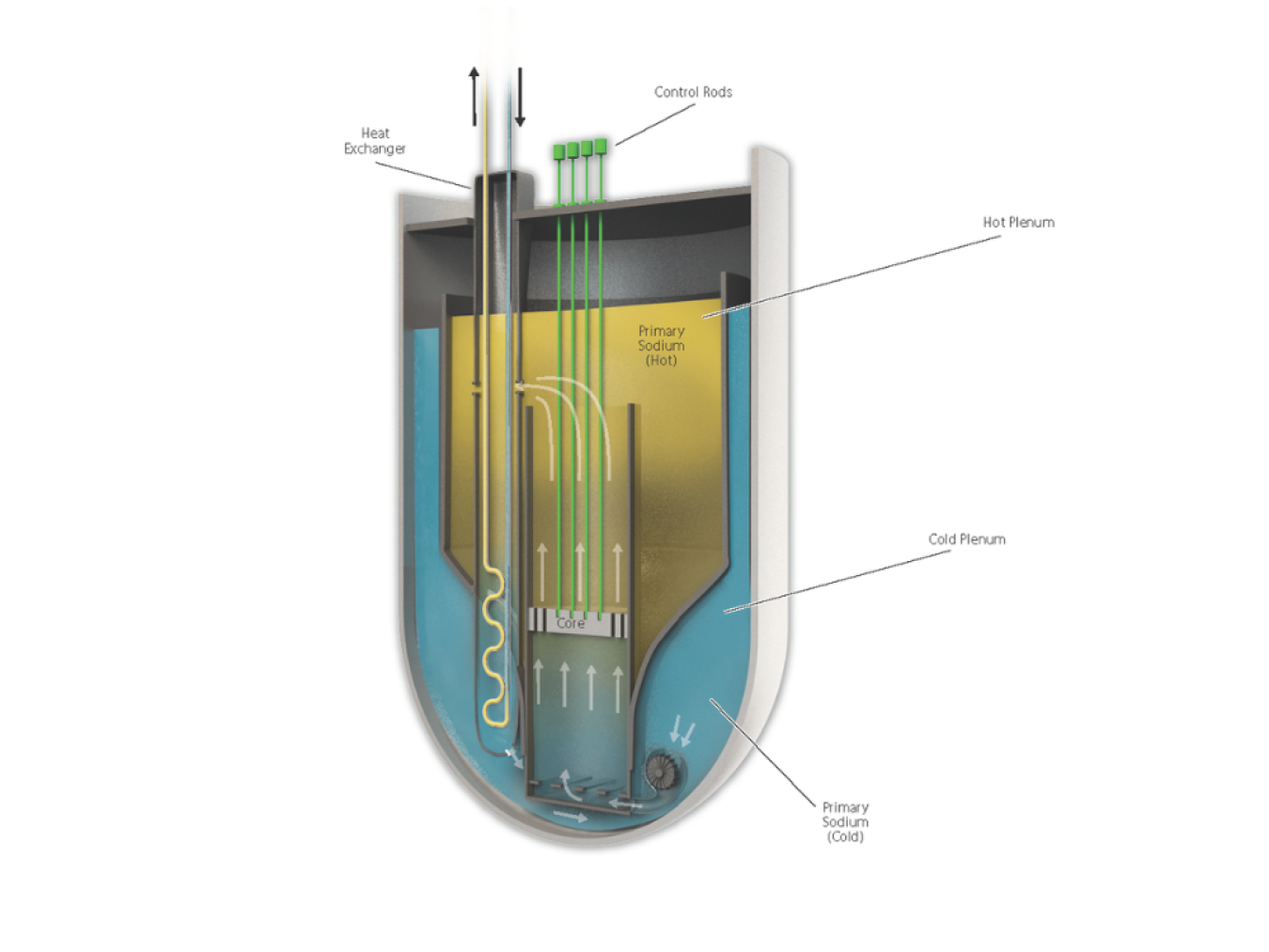

They primarily use liquid metals like sodium or lead to cool the reactor without slowing down the neutrons.

When these “fast neutrons” cause fission, additional neutrons are released, which lead to a unique benefit of fast reactors.

How Fast Reactors Work

Fast reactors can operate on metallic, ceramic, or molten salt fuels to generate heat during fission.

They are primarily cooled by liquid metals, but can also use gas, or molten salts as long as no moderator is present to slow down the neutrons.

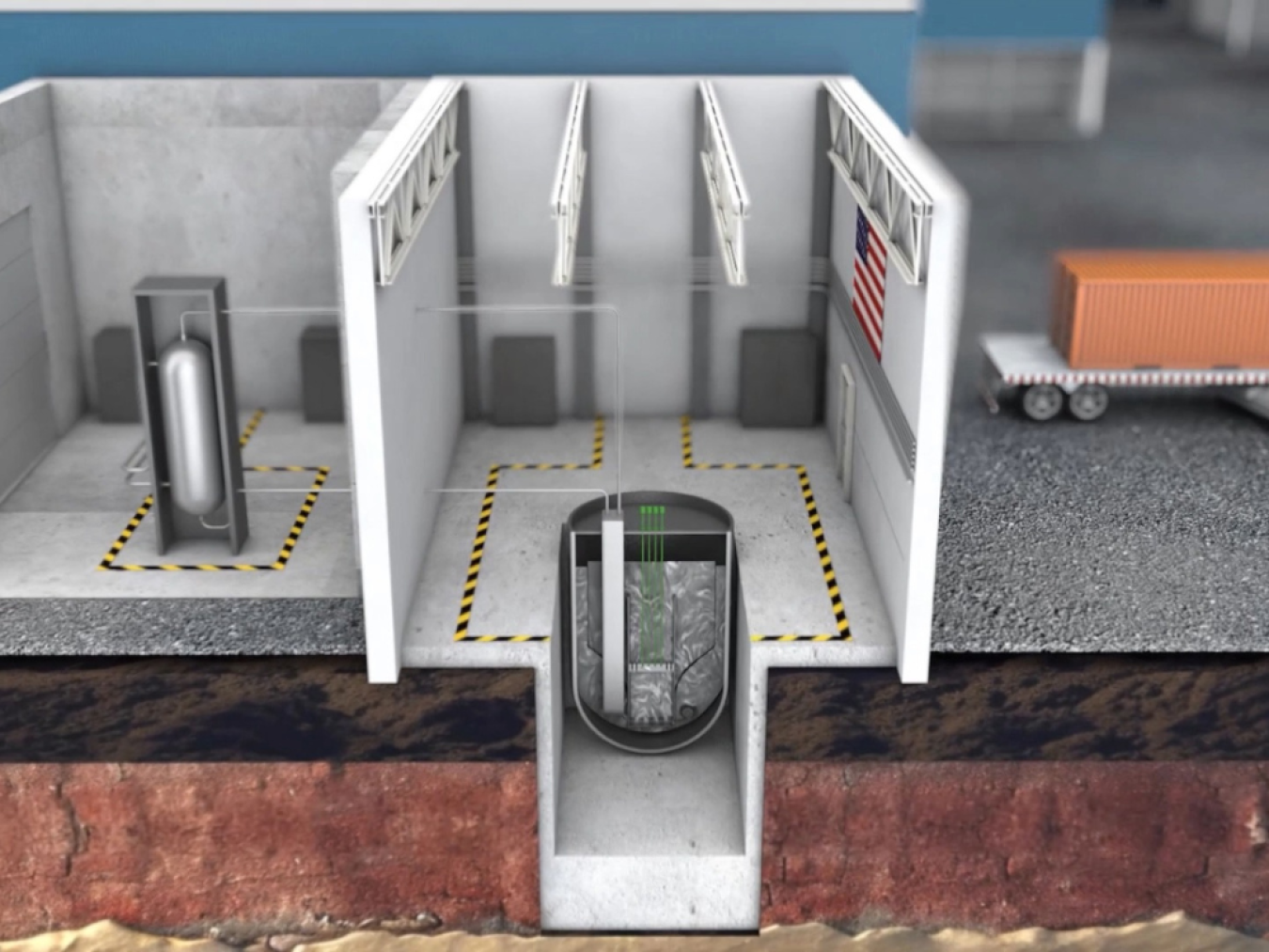

Mechanical pumps are used to circulate the coolant through the reactor core to remove heat from the fuel.

The coolant then transfers heat directly to a water loop or through intermediate loops that eventually turn the water to steam.

The steam then spins a turbine to generate electricity and is later condensed back into water for reuse. The main coolant circulates back to the core to repeat the process.

Benefits of Fast Reactors

Fast reactors offer several advantages over water-cooled commercial reactors.

Fuel Efficiency

High-energy neutrons produced in fast reactors allow them to extract 100 times more energy out of the same type of fuel used in water-cooled reactors.

That's because the extra neutrons created during the fission process can convert virtually all of the unused uranium (which makes up about 95% of the fuel in water-cooled reactors) into new plutonium atoms that can easily fission.

This would result in 100 times less uranium required to produce the same amount of energy as water-cooled systems if the fuel is continuously recycled in a fast reactor.

Waste Management

The continuous recycling of nuclear fuel in fast reactors could also lead to a 90% reduction in nuclear waste.

High-energy neutrons are more efficient at fissioning long-lived actinides in nuclear fuel that can take hundreds of thousands of years to decay to natural levels.

Fast reactors can be optimized to break up these actinides into smaller fission products that decay to natural levels after just 300 years, making them much easier to manage.

Enhanced Safety

Most U.S.-based designs use liquid metals like sodium or lead to efficiently transfer heat away from the core and are able to operate at low pressures due to their high boiling points, which improves the overall safety of the system.

The metallic fuel primarily used in these designs offers additional safety benefits by expanding when the temperature rises significantly in the core. This thermal expansion naturally reduces the chain reaction in the fuel to automatically shut down the reactor during unforeseen temperature behavior.

Performance

Fast reactors operate at higher temperatures than water-cooled reactors thanks to the superior heat transfer properties of its liquid metal coolants.

The higher temperatures allow the reactor to convert more of its thermal energy into electricity or process heat for manufacturing.

The liquid metal coolant also allows fast reactors to operate at a higher power density, making them capable of producing up to three times the power levels of similar-sized water-cooled reactors.

History of Fast Reactors in the United States

The United States has a rich history in the development, demonstration and commercial operation of fast reactors dating back to the early 1950s.

Experimental Breeder Reactor I - Operated from 1951 to 1963 in Idaho and became the world’s first reactor to generate electricity from nuclear power.

Experimental Breeder Reactor II - Operated from 1964 to 1994 in Idaho and successfully demonstrated its ability to shut down without operator action during a series of heat removal tests during the 1980s.

Fast Flux Test Facility - Operated from 1982 to 1992 in Hanford, Washington to help test fuels, materials, and components for liquid metal fast reactors for the U.S. Department of Energy.

Integral Fast Reactor – A program based on EBR-II that was active from 1984 to 1994 at Argonne National Laboratory to demonstrate the recycling of spent fuel from nuclear reactors and to advance research on safety and efficiency of fast reactor technologies.

Fermi-I - Operated from 1966 to 1972 as the first commercial fast reactor in the United States.

The U.S. Department of Energy supports the development of fast reactors through its Advanced Reactor Technologies Fast Reactor Program in coordination with university and industry partners.