Highest priority cleanup project at Oak Ridge National Laboratory is removing nation’s inventory of Uranium-233 from storage in the world’s oldest operating nuclear facility

Office of Environmental Management

April 1, 2025Isotek employees have begun processing radiochemical processing-06 material in hot cells as they advance the Uranium-233 Disposition Project, the highest priority cleanup project at Oak Ridge National Laboratory.

Highest priority cleanup project at Oak Ridge National Laboratory is removing nation’s inventory of Uranium-233 from storage in the world’s oldest operating nuclear facility

OAK RIDGE, Tenn. — The Oak Ridge Office of Environmental Management (OREM) and contractor Isotek have begun processing a new set of material as part of the Uranium (U)-233 Disposition Project.

Together, OREM and Isotek are eliminating the nation’s inventory of U-233 from storage in the world’s oldest operating nuclear facility, located at Oak Ridge National Laboratory (ORNL).

U-233 presents risks and is costly to keep safe and secure. Originally created in the 1950s and 1960s for potential use in reactors, it proved to be an unviable fuel source. Its removal is the highest priority cleanup project at ORNL.

Employees are now processing material known as radiochemical processing (RCP)-06. It differs from portions of the inventory they’ve processed previously. The material has also presented unique challenges, prompting years of preparation before treating it.

“It is much larger in mass and in a significantly different form,” said Isotek Nuclear Safety Manager Dana Cresci.

Workers place a radiochemical processing-06 canister in a hot cell for processing. The Hanford and Savannah River sites sent this material to Oak Ridge in the 1970s. It was originally in a liquid form, but the material was solidified in the 1980s for safe long term storage.

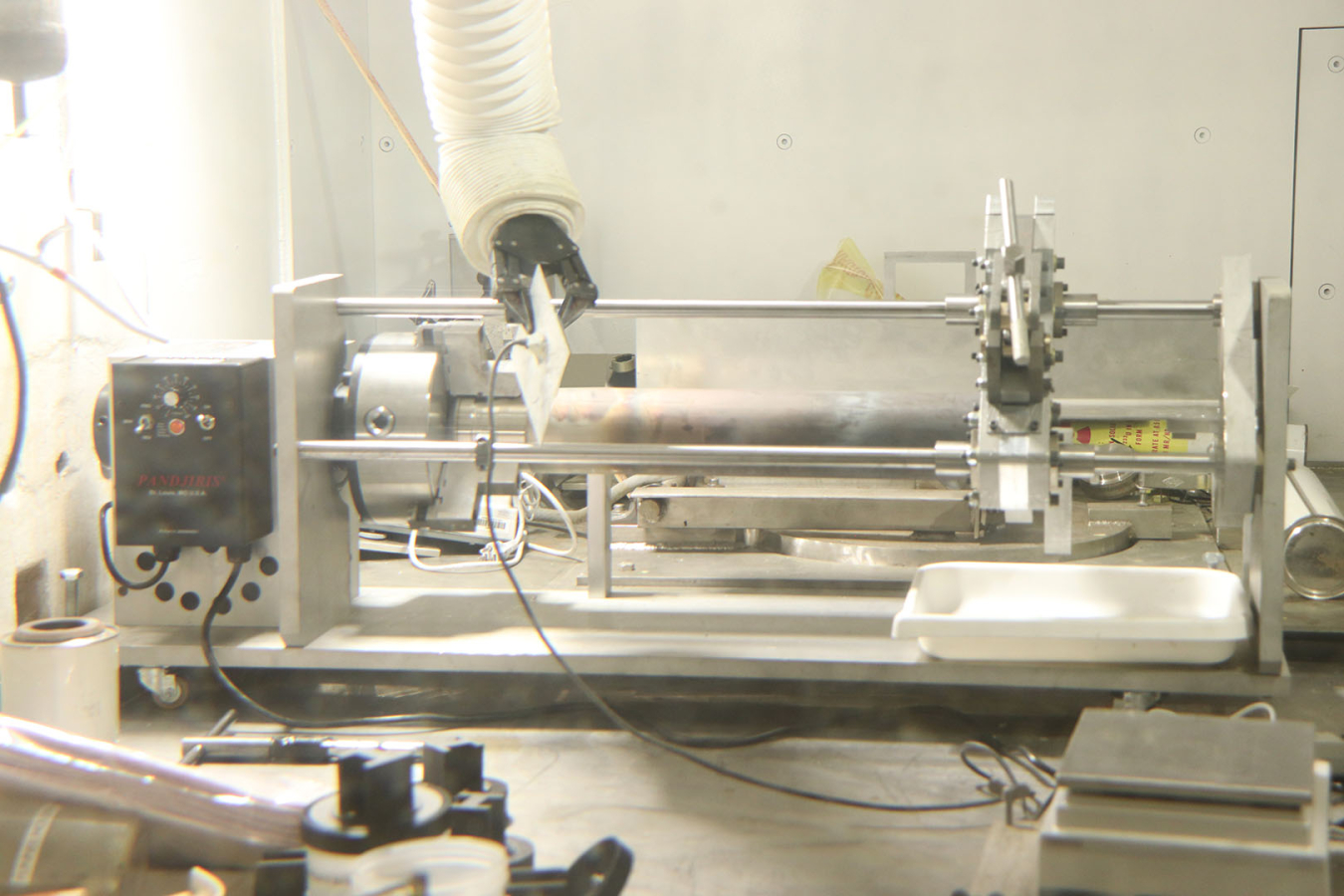

Up to this point, all material Isotek has processed using heavily shielded rooms called hot cells has been in the chemical compound form of oxide or a powder-like form. The RCP-06 material is in a 2-foot-long, solidified, ceramic cylinder.

Much of the preparation went into designing a cutting device that could divide the material into segments small enough to meet critical mass restrictions during processing. These limits enhance safety and reduce risks associated with fissile material by helping prevent potential reactions.

“It’s basically like cutting through concrete,” said Isotek Senior Processing Technical Advisor Karl Thomas. “Performing these procedures within the limited confines of a hot cell is no small feat.”

RCP-06 canisters contain U-233 that the Hanford Site in Washington and Savannah River Site in South Carolina sent to Oak Ridge in the 1970s. The material was originally in a liquid form, but it was solidified in the 1980s for safe long term storage. Oak Ridge was designated the location for U-233 storage.

“Getting to this point has taken a lot of hard work by the entire Isotek team,” said Isotek President and Project Manager Sarah Schaefer. “Each phase of processing presents unique challenges, and Isotek is driven to successfully address them.”

Radiochemical processing-06 material is removed from its storage container before it is divided into segments small enough to meet critical mass restrictions during processing.

Isotek will continue processing the first subset of RCP-06 canisters through mid-year. The remaining canisters require further planning due to the high mass of their contents, but the project expects to begin processing those in 2026.

Isotek has processed and removed approximately 40% of remaining U-233 inventory stored at ORNL.

Additionally, Isotek continues to extract extremely rare medical isotopes during processing operations for next generation cancer treatment research. These isotopes are key to a promising form of treatment that is showing success in clinical trials against types of cancer previously thought untreatable.

Currently, only one gram of those isotopes is available worldwide outside of Oak Ridge. However, through this project, Isotek is extracting an estimated 40 grams. That is enough to create 100 times more doses of treatments annually than is currently available worldwide. So far, Isotek has extracted nearly 15 grams.

-Contributor: John Gray

To receive the latest news and updates about the Office of Environmental Management, submit your e-mail address.