The U.S. Nuclear Weapons Stockpile

NNSA is responsible for maintaining a safe, secure, reliable, and effective nuclear weapons stockpile without the use of underground nuclear explosive testing. A key part of these warheads are plutonium “pits,” which are spherical shells of plutonium about the size of a bowling ball. Due to factors including plutonium aging, safety and security advancements, global risk, and weapons modernization, these pits need to be replaced from time to time, but for nearly three decades, the United States has not had the ability to produce them in the quantities required for the nuclear weapons stockpile.

To meet this requirement, NNSA’s Defense Programs plans to restore the production of plutonium pits for the Nation’s nuclear deterrent. The infrastructure and critical skills required for pit production and other plutonium capabilities are essential to the Nuclear Security Enterprise. Given the uncertainties regarding plutonium aging and the evolving geopolitical landscape, the United States cannot postpone reestablishing this critical capability. Delaying the restoration of this capability could result in significant cost increases and risks to national security. NNSA and the Department of Defense continue the drive to enhance the safety of our nation’s nuclear weapons.

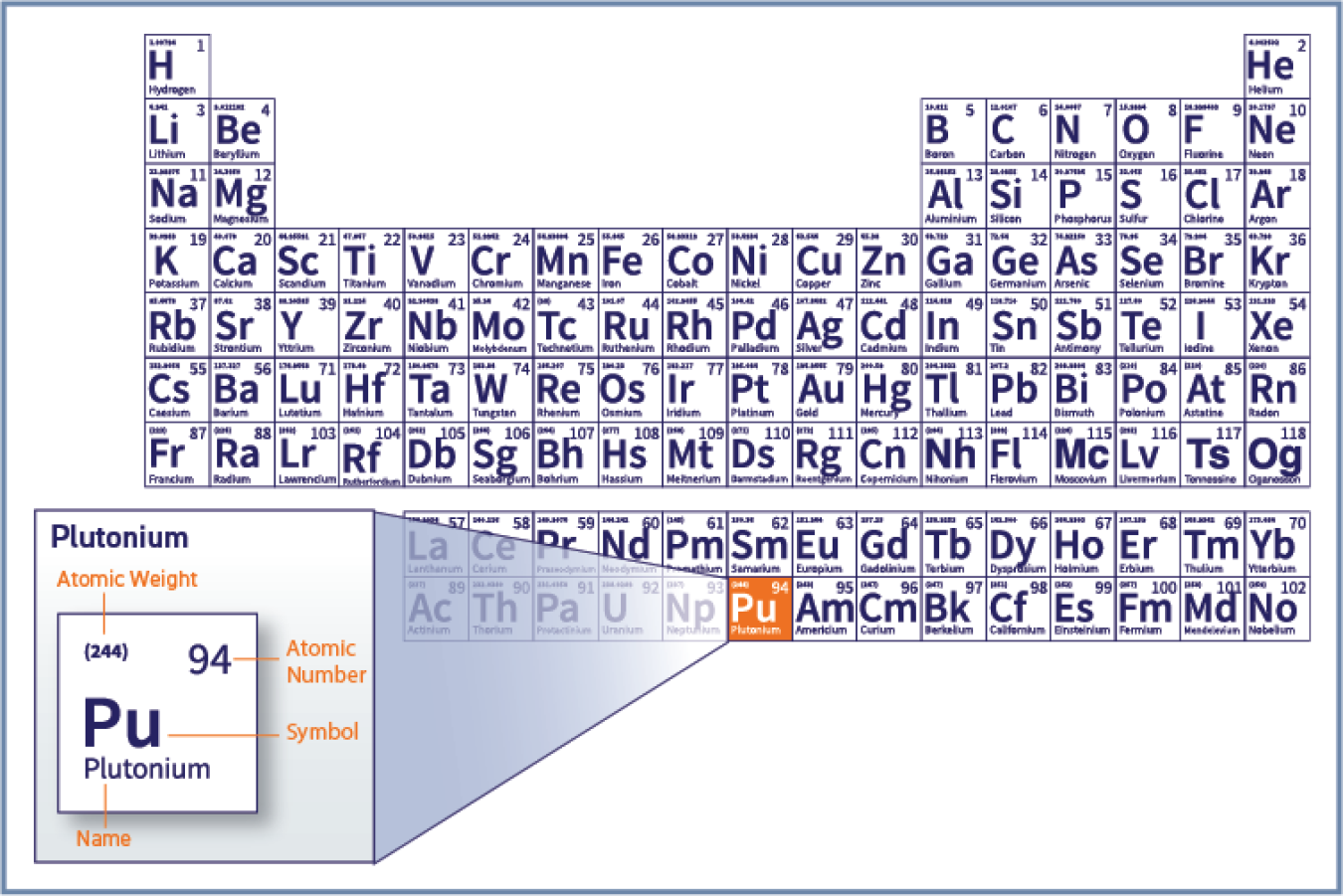

Plutonium's placement on the periodic table

Plutonium's placement on the periodic table Molten plutonium

Molten plutoniumPlutonium (Pu) was discovered in 1940 by Glenn Seaborg and colleagues at the University of California, Berkeley, and is a radioactive metallic element with the atomic number 94 (the number of protons in the nucleus). This reactive metal has a bright silvery-gray appearance, similar to nickel. There are various isotopes of plutonium that are “fissionable,” meaning the atom’s nucleus can easily split apart if struck by a neutron. Each isotope of plutonium has a different “half-life,” which is the time it takes for half of the atoms in a given sample to decay.

Various uses have been found for plutonium as a source of energy. For example, plutonium-238 has been used to power batteries for pacemakers and to keep National Aeronautics and Space Administration (NASA) probes operating deep into space.

NNSA uses plutonium in nuclear warheads the agency supplies to the Department of Defense. Therefore, the element plays an integral role in ensuring that the U.S. nuclear stockpile remains effective.

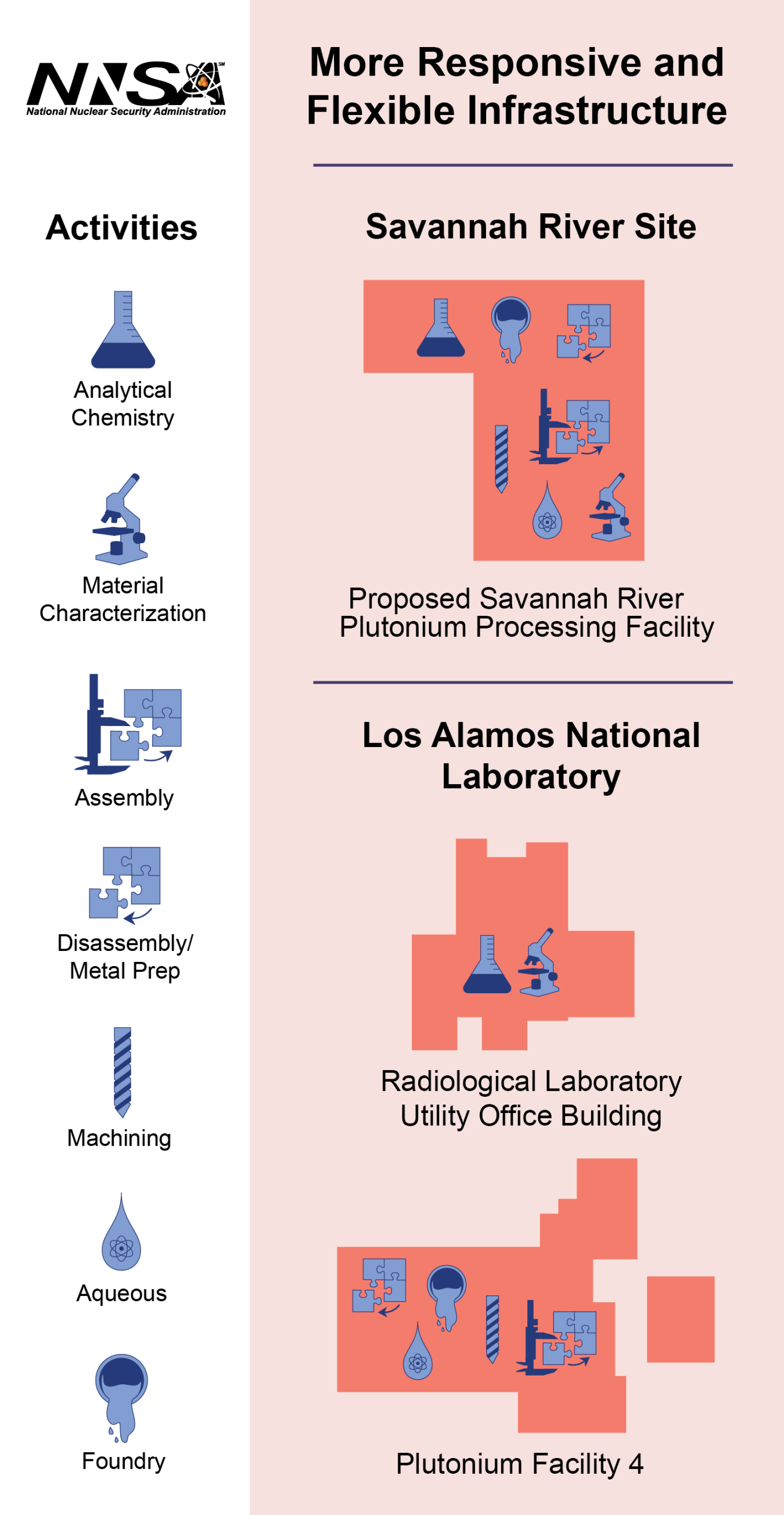

NNSA is working to increase its plutonium processing and pit-manufacturing capabilities to meet requirements to produce no fewer than 80 pits per year, as close to 2030 as possible. NNSA proposes to meet this requirement by recapitalizing facilities at two existing sites.

The current approach includes completing the modernization and expansion of Plutonium Facility 4 (PF-4), currently the only plutonium center within the Nuclear Security Enterprise at Los Alamos National Laboratory in Los Alamos, New Mexico, and repurposing the former Mixed Oxide (MOX) Fuel Fabrication Facility at the Savannah River Site near Aiken, South Carolina as the Savannah River Plutonium Processing Facility (SRPPF). The two-site approach has been informed by robust engineering assessments and workforce analyses, completed by experts at U.S. national security laboratories. The Nuclear Weapons Councilcertified NNSA’s approach in May 2018.

Plutonium pits are a key component for nuclear weapons. Today, the U.S. capability to produce them is limited to research and development pits that are unsuitable for stockpile use. The proposed approach to pit production is driven by several factors:

- Safety and security advancements

- Plutonium aging

- Global risk

This approach to revitalize pit production capabilities would leverage efficiencies and include investments in a modest pit production capability to address requirements. Modernization of the nuclear deterrent would utilize a combination of reusing existing plutonium pits and producing new ones.

Why dedicate two sites to pit production?

The two-site approach would ensure a more responsive and resilient nuclear weapons infrastructure that can adapt to shifting requirements and counter future threats.

Studies of NNSA’s approach show that having two geographically separated plutonium pit production facilities supports resilience from external threats and hazards, and provides NNSA with the flexibility and resilience to mitigate shutdowns, incidents, or other impacts to operations at a given site.

Los Alamos National Laboratory’s PF-4 currently contains the sole U.S. pit production capability and will reach its 50-year design life before 2030. Although NNSA continues to invest in facility sustainment projects to extend the life of PF-4 and reduce public and operations safety risk, a single-site approach to pit production poses a significant risk as a shutdown or incident could disable this critical capability. Diversifying this work across Los Alamos National Laboratory and the Savannah River Site would provide both long-term resiliency as well as lower short-term risk for producing no fewer than 80 pits per year as close to 2030 as possible.

An employee at Los Alamos National Laboratory prepares to cast plutonium.

An employee at Los Alamos National Laboratory prepares to cast plutonium.Manipulating plutonium requires special infrastructure and highly trained teams of experts. This material is radioactive and undergoes alpha decay, which makes it warm to the touch. Plutonium is also toxic – it collects in the bones and presents an inhalation hazard.

To ensure that workers, the public, and the environment are protected from the hazardous effects of plutonium, NNSA trains staff on important safety topics including handling of special nuclear materials, criticality safety, and appropriate transport and disposal.

NNSA’s Office of Secure Transportation is responsible for safely transporting NNSA’s warheads, components, and special nuclear materials. This office is responsible for ensuring the safe movement of all plutonium.

The National Environmental Policy Act (NEPA) is a law enacted by Congress in 1970. The act requires Federal agencies to undertake an assessment of the potential environmental effects of their proposed actions before making a decision. NEPA processes ensure that government agencies are making well-informed decisions while giving citizens the opportunity to provide input on governmental programs, through mechanisms such as public scoping meetings and comment periods.

Throughout the implementation of the proposed two-site pit production approach, NNSA will comply with all NEPA requirements.

Learn more about NNSA NEPA documents.

Learn more about the NEPA law and the Department of Energy’s NEPA guidance.

The Rocky Flats Plant in 1995

The Rocky Flats Plant in 1995As the world entered the nuclear age, the United States produced a significant amount of plutonium in support of its critical defense missions. During the Cold War, the United States could produce more than 1,000 pits per year at the Rocky Flats Plant in Colorado.

This mission was previously supported by additional facilities, including the Hanford Site, Savannah River Site, Los Alamos National Laboratory, and Lawrence Livermore National Laboratory. After the Cold War ended, each of these sites refocused their missions on other areas critical to national security, with the exception of the Rocky Flats Plant which closed in the 1990s.

Currently, the sole plutonium pit production capability in the United States is located at Los Alamos National Laboratory’s PF-4 building. NNSA now proposes that the Savannah River Site, which produced plutonium during the Cold War, repurpose existing infrastructure for a facility (i.e., MOX Facility) to support this critical defense mission. This two-site approach would provide resiliency for pit production operations, mitigating risk in the event of a shutdown or disruption.

See “How is NNSA addressing plutonium pit production?” above for more.