The entire rainbow of radiation that the human eye can see makes up just 0.0035 percent of the spectrum. At NNSA it helps us ensure that we’re working with pure materials, watch for missile launches, and create flat lenses.

National Nuclear Security Administration

June 16, 2025The entire rainbow of radiation that the human eye can see makes up just a tiny portion of the electromagnetic spectrum – about 0.0035 percent. This range of wavelengths is known as visible light. At NNSA visible light helps us ensure that we’re working with pure materials, watch for missile launches, and create flat lenses.

Structured light: Shining a path to consistent outcomes

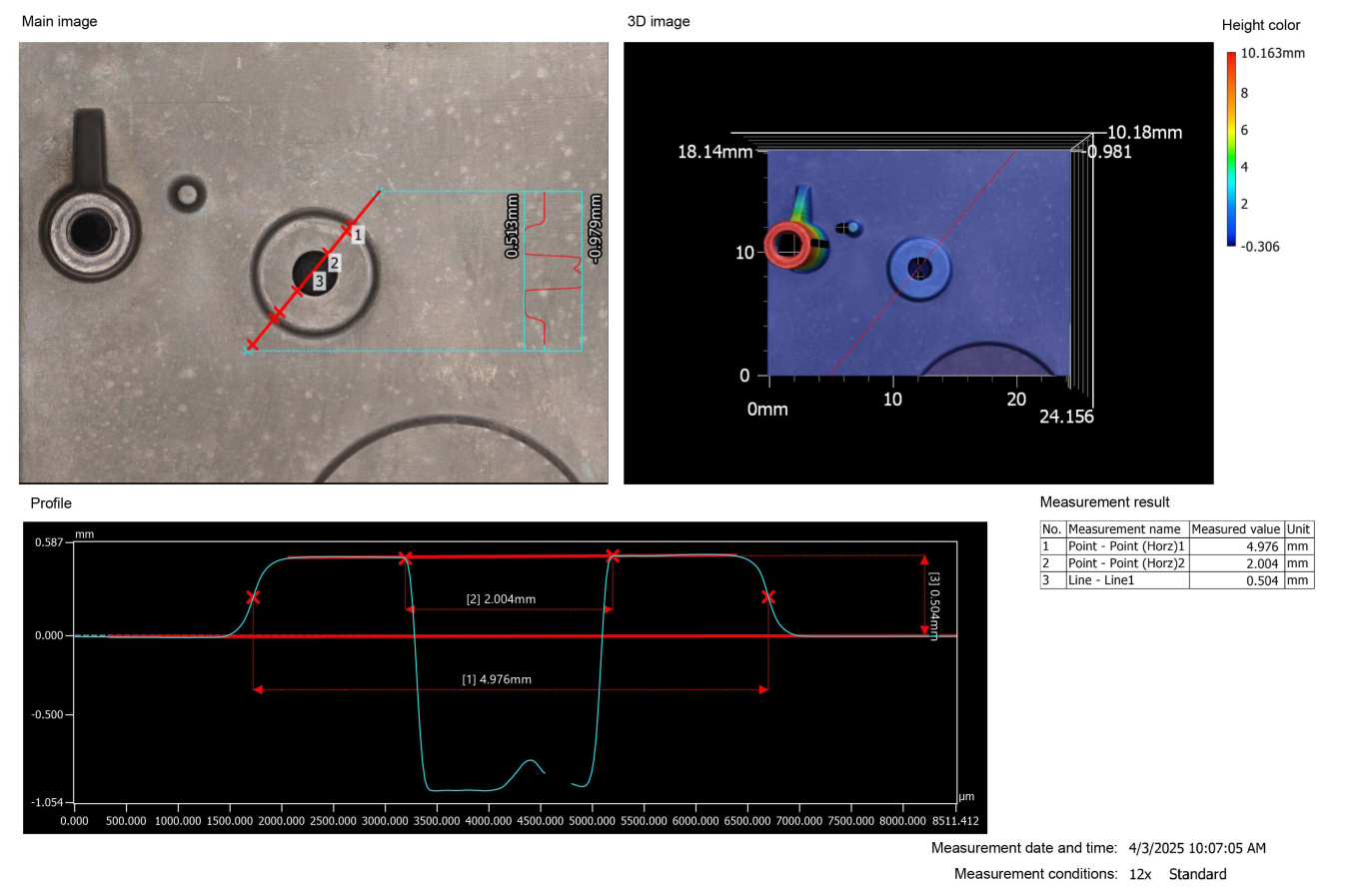

NNSA’s work on weapons components must be precise. Really precise. Even the potential for minor damage due to regular handling, however small, is no minor detail. To keep track of this, workers at the Pantex Plant regularly take hyper-accurate measurements to ensure all parts remain within specification.

Pantex technicians combine traditional and modern approaches to measure component scratching. This helps improve the quality of the products NNSA delivers to the nation’s stockpile. The key metrics are reliability and repeatability in the measurements.

Pantex’s Technical Development Department is testing the use of structured-light technology as one way to do this. Structured light is cast onto the surface of a component. Then they analyze the light’s reflection for banding and bending caused by changes in the object’s surface. Later, the department studies these bands and bends closely to figure out if the exact geometry of the surface has changed. They do this by creating a three-dimensional digital copy of the surface. Then they precisely measure that digital replica to determine whether the part is still up to snuff.

Clear materials are challenging because the instrument needs visible light to create the lines of light and shadow. When the light passes through transparent objects, they become invisible to the detector. Pantex engineers are working to overcome this.

Combining structured light and more conventional technologies lets Pantex take accurate and highly repeatable measurements to support production of the deterrent.

When it’s got to be very, very, very pure

At the Savannah River Site (SRS), teams will use the entire electromagnetic spectrum as one way to ensure they can produce pure materials.

In the 2030s, SRS will start making plutonium metal parts for nuclear weapons. It’s important that those parts be extremely pure to ensure that they work properly.

To do it, SRS will use one method called inductively coupled plasma with emissions spectroscopy and mass spectroscopy. Used together, these are the gold-standard in finding trace impurities.

Technicians need to meet exacting specifications to ensure that the plutonium parts are up to snuff. Used together, the two spectroscopy techniques can detect the equivalent of a drop of water in a backyard swimming pool (parts per trillion) – or even a drop of water spread across a thousand of those pools (parts per trillion).

Emissions spectroscopy works by exposing samples to plasma, which causes them to reach a more “excited” state. As the electrons return to their normal state, they emit a certain wavelength of light unique to each element in the sample. The light intensity is based on the concentration of elements within the sample. Every element has a wavelength fingerprint, so technicians can tell when a sample is pure or not. (And to be totally accurate, the wavelength fingerprint could appear beyond what we see as visible light.)

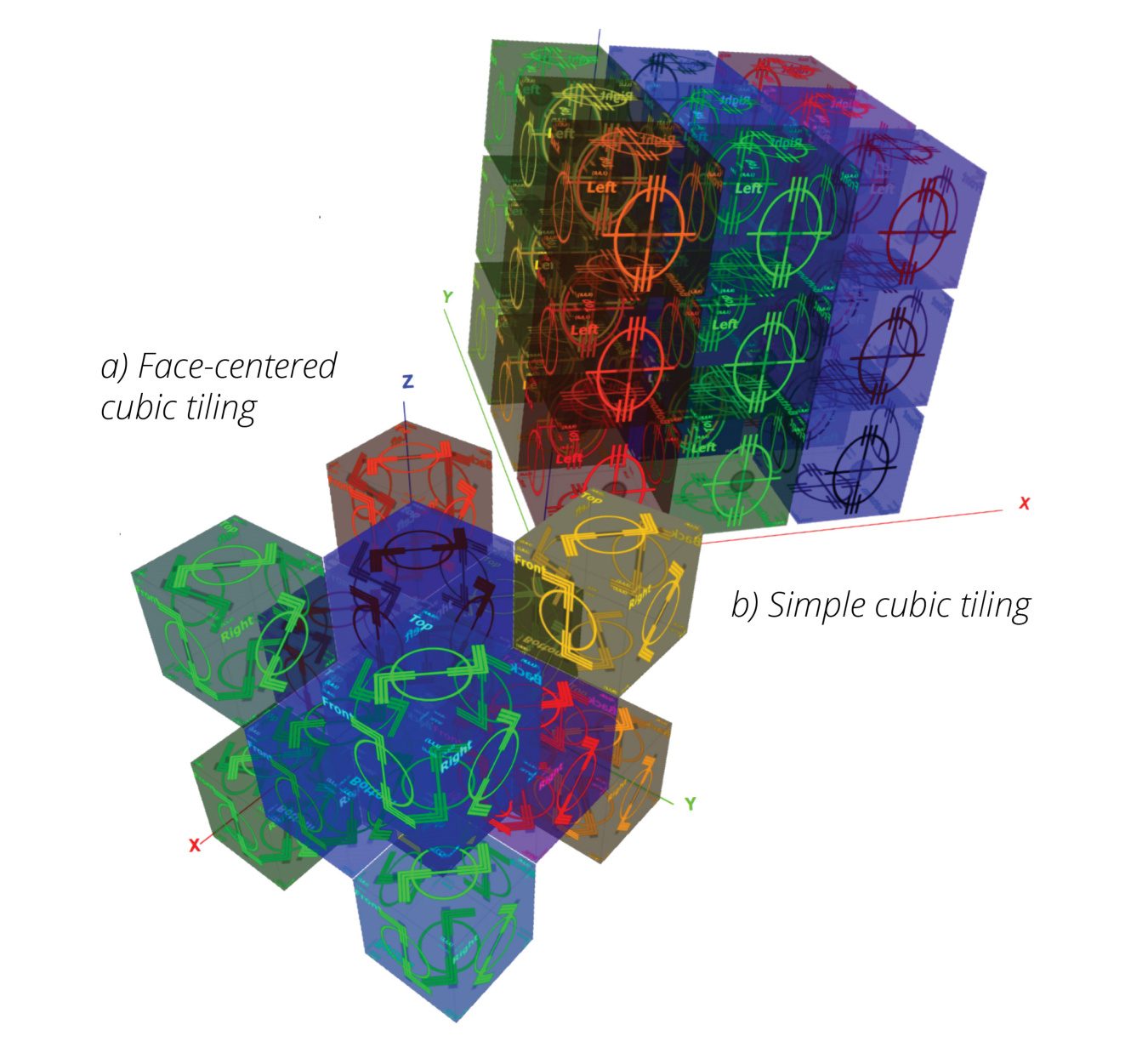

Creating flat lenses

Metamaterials can be better understood by thinking about carbon. Both diamonds and graphite are made of carbon. The difference is the 3D lattice structure of each. Diamonds are transparent and one of the hardest materials known, while graphite is pliable and opaque. Similarly, Sandia National Laboratories engineers have figured out how to geometrically assemble artificial, microscopic structures in 3D arrangements to alter how materials interact with light, but the hit-or-miss method they have used to test their results is inefficient, costly, and time-consuming.

“We cannot possibly solve this problem by trial and error,” said Sandia scientist Ihab El-Kady. “Instead, we could do the opposite. We could say: ‘Here is the behavior I want. Now tell me what the metamaterial looks like.’”

Enter MIRaGE, a design software for metamaterials. It lets designers work backwards – deciding how they want the end material to modify light – and designing toward that. The software designs the 3D geometrical arrangement and shape just for that purpose. MIRaGE stands for Multiscale Inverse Rapid Group-theory for Engineered-metamaterials.

Today’s its goals are to allow engineers to make a metamaterial “invisible” or make a flat surface focus and concentrate light like a curved lens.

Someday, though, MIRaGE could include converting heat to electricity – enabling more fuel-efficient engines, and light-mixing technology for multicolored light sources.

Eyes in the sky

GPS technology is something many of us use when we are on the move – whether we’re on our phones, in our cars, or on a plane. But did you know that the same satellites helping you get home are also watching out for nuclear explosions?

In addition to carrying complex radios, nearly all of the GPS satellites that have ever orbited the Earth are equipped with Global Burst Detectors, which detect visible light. These sensors are always looking for the distinct flash of a nuclear explosion in the atmosphere.

First developed at Sandia more than 60 years ago, satellites with Global Burst Detectors have kept watch for threats ever since, offering timely information to U.S. policymakers and the Department of Defense. The program is a key NNSA nonproliferation capability.

To this day, teams at Sandia continue to advance detection technology so that our adversaries know we’re always watching, always ready.

Research at NNSA spans the entire electromagnetic spectrum – take a look at how other frequencies help further the missions of the Nuclear Security Enterprise.