This pebble bed, high-temperature gas-cooled reactor can't melt down, according to X-energy.

January 5, 2021Dozens of U.S. companies are developing advanced reactor designs that will bring enhanced safety, efficiency, and economics to the nuclear energy industry.

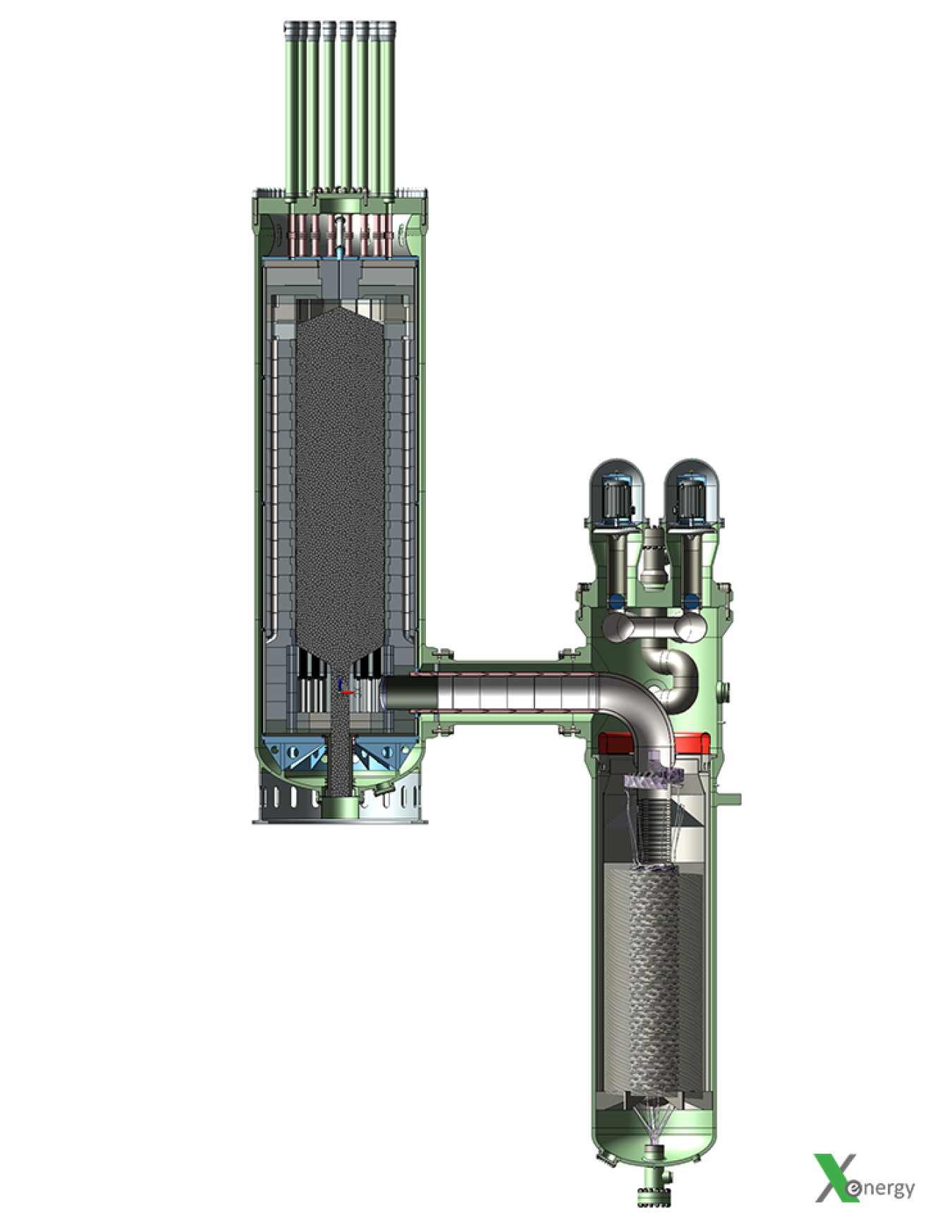

X-energy, located just outside the nation’s capital in Rockville, Maryland, is working on a pebble bed, high-temperature gas-cooled reactor that the company says can’t melt down.

The company's Xe-100 reactor and specialized uranium-based pebble fuel could be available in the market as early as the late 2020s and is one of two designs that secured more than $2.5 billion in funding through the Bipartisan Infrastructure Law to demonstrate their technology.

How it Works

The Xe-100 is an advanced modular reactor with each unit designed to produce around 76 megawatts of electric power.

The reactor core is made of graphite and filled with 15.5% enriched fuel pebbles. Each pebble (roughly the size of a billiard ball) contains thousands of specially coated Tristructural Isotropic (TRISO) uranium fuel particles that are virtually indestructible.

The TRISO coating creates an airtight seal around the uranium kernel. This helps retain fission products and gases that are produced during operations and would allow the plant to be constructed within 500 meters of factories or urban areas.

The fresh pebbles are loaded in the reactor like a gumball machine and helium is pumped down through the pebble bed to extract the heat into a steam generator that produces electricity.

The reactor continuously refuels by adding fresh pebbles daily in at the top, as older ones are discharged from the bottom of the core. Each pebble remains in the core for a little more than three years and are circulated through the core up to six times to achieve full burnup. The spent fuel is then placed directly into dry casks and stored on-site—without the need for interim or active cooling.

Benefits of the Xe-100

The Xe-100 is designed to operate at high temperatures to produce electricity more efficiently. The high-temperature helium gas can also be used in energy-intensive processes that currently rely on fossil fuels, such as hydrogen production and petroleum refining.

This reactor concept can also be designed to incorporate passive cooling through natural conduction, thermal radiation and convection in the case of a loss of helium coolant—meaning it doesn’t have to rely on large local water sources, pumps, or safety systems to prevent fuel damage.

Other benefits:

- Ability to load follow (from 100% to 40% power within 20 minutes), making the plant complementary to maintaining a stable load on a grid that includes renewables.

- Continuous fueling and on-site fuel storage, delivering high availability (93-95%) while ensuring plant resiliency.

- Reduced construction time (2.5 – 4 years for a 300 MWe plant).

- Factory-produced major components, enabling improved quality control while reducing per unit costs.

What’s Next?

X-energy was awarded $80 million in initial funding to demonstrate a four-unit, 320 MWe plant within the next seven years through the U.S. Department of Energy's Advanced Reactor Demonstration Program.

Dow and X-energy agreed to build a plant at a Dow-owned chemical plant in Seadrift, Texas.

The company completed its basic design and has successfully fabricated its first fuel pebbles using natural uranium at a pilot scale fuel facility, on-site at the Oak Ridge National Laboratory.

X-energy was awarded additional DOE assistance to design a commercial scale “TRISO-X” fuel fabrication facility and submitted a license application to the Nuclear Regulatory Commission in 2022.

The company plans to complete the TRISO-X Facility construction by the mid-2020s.

Since the TRISO uranium particle is the basis for multiple advanced reactor fuel designs, the TRISO-X Facility could become a key enabler for deployment of the U.S. advanced reactor industry over the next several years.

DOE previously invested more than $30 million through two separate cost-shared agreements to further develop the Xe-100 design and demonstrate a production process for its TRISO fuel.

Learn more about this project.

.........................

*This article was updated in May 2023