In 2021, the U.S. Department of Energy’s (DOE) Sustainability Performance Division recognized 9 winners and 4 honorable mentions from DOE sites. Despite pandemic related challenges, these award winners persevered and remained dedicated to implementing sustainable solutions across the DOE complex. Congratulations to everyone involved in making these projects successful!

Learn more about the 2021 DOE Sustainability Award winners below.

Lifetime Achievement awards recognize long-time DOE Sustainability Champions who have dedicated significant amounts of time to making DOE sustainable.

Wayne P. Carlton

Wayne P. CarltonWayne P. Carlton, Y-12 National Security Complex

For more than 40 years, Wayne Carlton has embraced sustainability, implemented green concepts, and increased resilience at DOE. Wayne has been a sustainability champion from the beginning of his career as a chemical engineer at the Hanford Site and then at the Y-12 National Security Complex since in 1989. His commitment, support, and experience has led to significant sustainability efficiencies across both sites. He has continued to be a strong proponent for sustainability whether through his efforts working on the deactivation and decommissioning of a tank car, which became a model across DOE; working in technology development; or promoting the computerization of outdated, time-consuming paper-based processes. Wayne is known for going above and beyond to promote sustainability by volunteering to evaluate and implement sustainable measures as well as catalyzing behavioral change by recruiting others to embrace and implement sustainable actions.

Sustainability Champions are individuals who make an effort to advance sustainability goals relating to sustainable buildings, water, waste, sustainable acquisition, etc.

Monica Witt

Monica WittMonica Witt, Los Alamos National Laboratory

Monica Witt is a tireless champion working to improve sustainability throughout NNSA and the Department. She served as the chair of the Energy Facility Contractors Group/Sustainability and Environment Subgroup for several years, fostering collaboration and communication between the sites. As Los Alamos National Laboratory’s Sustainability Officer, Monica is dedicated to turning their Site Sustainability Plan into action and has played a pivotal role in developing water reuse strategies for their High Performance Computing Division. She is also leading the effort to identify new sources of on-site renewable energy. Monica has led the Laboratory’s Sustainability Program for over ten years and helped it grow into a $3M per year program that drives sustainable solutions across the Laboratory! Her leadership resulted in the Lab reducing energy usage by 8.3% from 2015 and water usage by 20% from 2007, improving site operations, and reducing greenhouse gases attributable to LANL operations.

Kelly Gant

Kelly GantKelly Gant, Kansas City National Security Campus

Over the last five years, Kelly Gant has actively sought to reduce the volume of production waste sent to both incinerators and landfills, as well as increase the sustainability efforts of the Kansas City National Security Campus. Kelly reevaluated and recharacterized the production waste streams that were previously sent to a landfill or incinerator and diverted more to metal recyclers, e-scrap, battery recyclers, water treatment, precious metals recovery, and fuel blending. After reducing waste through the reevaluation process, Kelly started a new program at the site that converts waste to energy. In FY 2020, his efforts led to approximately 97% (1,711,916 lbs.) of production waste to be reused/recycled/reclaimed, 2.3% incinerated, and only 0.8% sent to a landfill.

Nicole Rinaldi

Nicole RinaldiNicole Rinaldi, Sandia Field Office – Honorable Mention

When the site was uncertain of the sustainable building regulations, Nicole Rinaldi took the initiative to become an expert in the 2016 and 2020 Guiding Principles released this past December. She created a systematic approach to sustainable building design and construction as well as added that approach to Sandia’s Design Manual and Specifications. By ensuring that these documents have the Guiding Principle requirements, Nicole helped create a future for Sandia that is more energy efficient and environmentally sustainable. Furthermore, since additional requirements and third-party certification are costly, Nicole worked with Sandia’s Projects team to clarify the requirements for their architecture, engineering, and construction partners - allowing them to design and construct buildings that comply with the Guiding Principles at lower costs.Outstanding Sustainability Programs or Projects are sustainable programs or projects that reduce costs and increase efficiency.

ANL’s energy-use analysis and functional testing at campus buildings. Re-plumbed piping system to switch potable water to treated canal water.Argonne National Laboratory’s Energy & Water Reinvestment Program

Argonne National Laboratory’s (ANL) Energy and Water Reinvestment Program was launched in 2008 as a collaboration between the Infrastructure Services Division and the Office of the Chief Financial Officer to help reduce the Lab’s operating costs and meet Federal energy and water goals. Under the Reinvestment Program, cost savings are calculated annually from completed energy and water savings projects. Funding equivalent to those annual savings is then provided to the program for reinvesting in projects the following year until the payback time of each project is reached. Argonne has also taken a further step to integrate the reinvestment program into the laboratory’s approach to facility and utility planning. In FY 2020, Argonne completed 23 energy and water savings projects that resulted in total savings of approximately $184,000. This was a 10-year high for annual savings!

Y-12 Recycling Program’s Long-term Sustainable Dedication Realizes Long-term Resilient Benefits

For more than a decade, the Y-12 National Security Complex’s Recycling Program has systematically expanded and in FY 2020 alone they recycled more than 3.8 million pounds of materials resulting in more than $1.1 million in cost avoidance. The Y-12 Recycling Program serves all onsite activities, the Uranium Processing Facility Construction, as well as several offsite locations, and involves continual input from subject matter experts from several Y-12 organizations. The framework that has facilitated this successful expansion includes an established procedure, integrated awareness efforts, a multi-organization team dedicated to recycling efforts, and efficient implementation of recycling efforts by the Y-12 Recycling Program staff and site personnel. The program has also established a dedicated Recycling Center that has helped improve the sustainability and resiliency of the site.

East Tennessee Technology Park/UCOR’s Completion of Vision – Honorable Mention

UCOR, an Amentum-led partnership with Jacobs, successfully completed the environmental cleanup at East Tennessee Technology Park (ETTP). Since the inception of its contract in 2011, UCOR has incorporated sustainability in its pursuit of what many recognize as one of the largest environmental cleanup missions in the nation’s history. Millions of cubic yards of soil and debris were remediated, millions of gallons of surface and groundwater were tested and treated, and several million square feet of paved and impervious surface area was removed. The site has been restored to a natural state through native grass and wildflower reseeding projects with around 3,500 acres of land placed into conservancy for the protection of wetlands, flora, and fauna. Through UCOR’s cleanup efforts, ETTP has transformed into a prospering multi-use industrial park surrounded by green spaces and has been designated a national park.

Innovative Approach to Sustainability awards are inventive ideas or methods and technologies that improve site sustainability and can be applied across DOE.

Lawrence Berkeley National Laboratory’s ISO 50001 Implementation

In September 2020, Lawrence Berkeley National Laboratory (LBNL) achieved third-party certification for its implementation of the ISO 50001 international standard as well as 50001 Ready recognition from DOE. Their innovative approach to applying the standard is “best in class” as they have fostered a cross-divisional team, applied the energy management principles to incorporate water management, promoted a culture of continual improvement, and maintained an ecosystem of online guidance to streamline implementation and ensure consistency. Lab-wide energy use intensity has decreased by 26% since FY 2015 and water use intensity has decreased by 28% from FY 2007.

LBNL's Energy & Water Management System Manual is the most critical piece of its ISO 50001 program, which is a publicly available resource for other organizations to conceptualize and implement ISO 50001.

Pacific Northwest National Laboratory’s Multi-Disciplinary Thinking for Sustainability & Resilience Planning

Pacific Northwest National Laboratory (PNNL) co-developed the Technical Resilience Navigator (TRN) with the National Renewable Energy Laboratory to assess, plan, and prioritize resilience solutions that enhance site resilience. The TRN uses a risk-informed approach to identify and address site-specific vulnerabilities, hazards, and threats to critical loads that support critical functions. PNNL has used the tool to prioritize site-level energy and water systems and determine potential solutions that could enhance overall site resilience. Thanks to PNNL’s work in co-developing and piloting the tool, the TRN is being used by a cohort of DOE sites to further enhance resilience across the Department.

Savannah River Site’s Passive Remediation to Destroy Chlorinated Volatile Organics with a Permeable Reactive Barrier – Honorable Mention

Savannah River Site (SRS) uses an innovative remedial technology known as a permeable reactive barrier (PRB) to treat contaminated groundwater. The PRB is constructed of zero valent iron (from recycled engine blocks) and injected into the subsurface to intercept and destroy solvent contamination in the groundwater as it passes through the barrier. The groundwater contamination that is being remediated is associated with their closed P-Area Reactor facility. The PRB works passively in the subsurface with no moving parts and works for decades. It is anticipated that the PRB will provide energy and project cost savings of over $35M over three decades of operation.

Strategic Partnerships for Sustainability are partnerships between sites or with other organizations that contribute positively to site sustainability.

Lawrence Berkeley National Laboratory’s Ongoing Commissioning Team

The Ongoing Commissioning (OCx) Team has established a successful strategy for collaboration between the two key players at Lawrence Berkeley National Laboratory (LBNL) best able to save energy and water in operations: the Facilities Division and its Sustainability Office (called Sustainable Berkeley Lab). Berkeley Lab’s OCx program focuses directly on operational efficiencies - improving the function of building systems and enhancing building services - while maintaining annual energy savings of around 42,000 MMBTU and annual water savings of around 20 million gallons. The OCx team has also created visualizations in an innovative data analytics platform called SkySpark that provide insights into the operation of complex building mechanical systems and enable the team to diagnose deficiencies.

Y-12 National Security Complex’s Partnership Results in Producing Sustainable Disinfectant during COVID-19 Pandemic

During the COVID-19 pandemic, Y-12 National Security Complex (Y-12) and Oak Ridge National Laboratory formed a unique partnership by sharing personal protective equipment and expertise to allow both sites to create their own disinfectant product, hypochlorous acid. This safe, environmentally friendly, sustainable, and effective disinfectant is inexpensive to produce, nontoxic, and eliminates the virus on hard surfaces after five minutes of contact. This innovation can be made on demand and stored for future use, which reduces their dependency on outside sources for disinfectant.

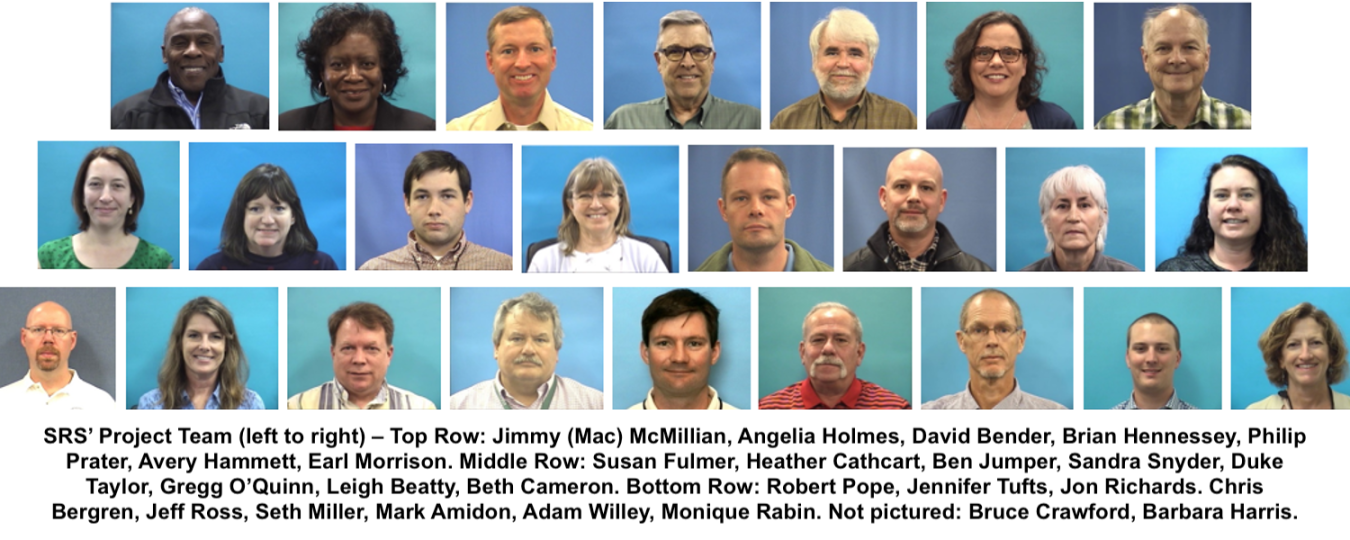

Moab’s Project Team (left to right) - Back Row: Luke Mattson, Nina Andrews, Stephanie Lein, Alex McCarty, Jose Fernandez, Russell McCallister. Front Row: James Ritchey, Liz Moran.

Moab’s Project Team (left to right) - Back Row: Luke Mattson, Nina Andrews, Stephanie Lein, Alex McCarty, Jose Fernandez, Russell McCallister. Front Row: James Ritchey, Liz Moran.Moab Uranium Mill Tailings Remedial Action Project’s Canyonlands Plant Salvage – Honorable Mention

The Moab Technical Assistance Contractor (TAC) created a partnership with the National Park Service at Canyonlands National Park to transplant over 100 native plant species to the Moab UMTRA Project. Canyonlands was planning for an upcoming construction project to support increasing visitation rates, which threatened native vegetation. To preserve these plants, the TAC team relocated these grasses and shrubs from the park to the Moab site. These native plants are drought tolerant, support the local ecosystem with nutrient rich seeds, and stabilize soils to reduce fugitive dust emissions.