RICHLAND, Wash. – One of EM’s most complex risk-reduction projects is expected to wrap up in coming months as crews demolish a Cold War relic a...

January 27, 2016

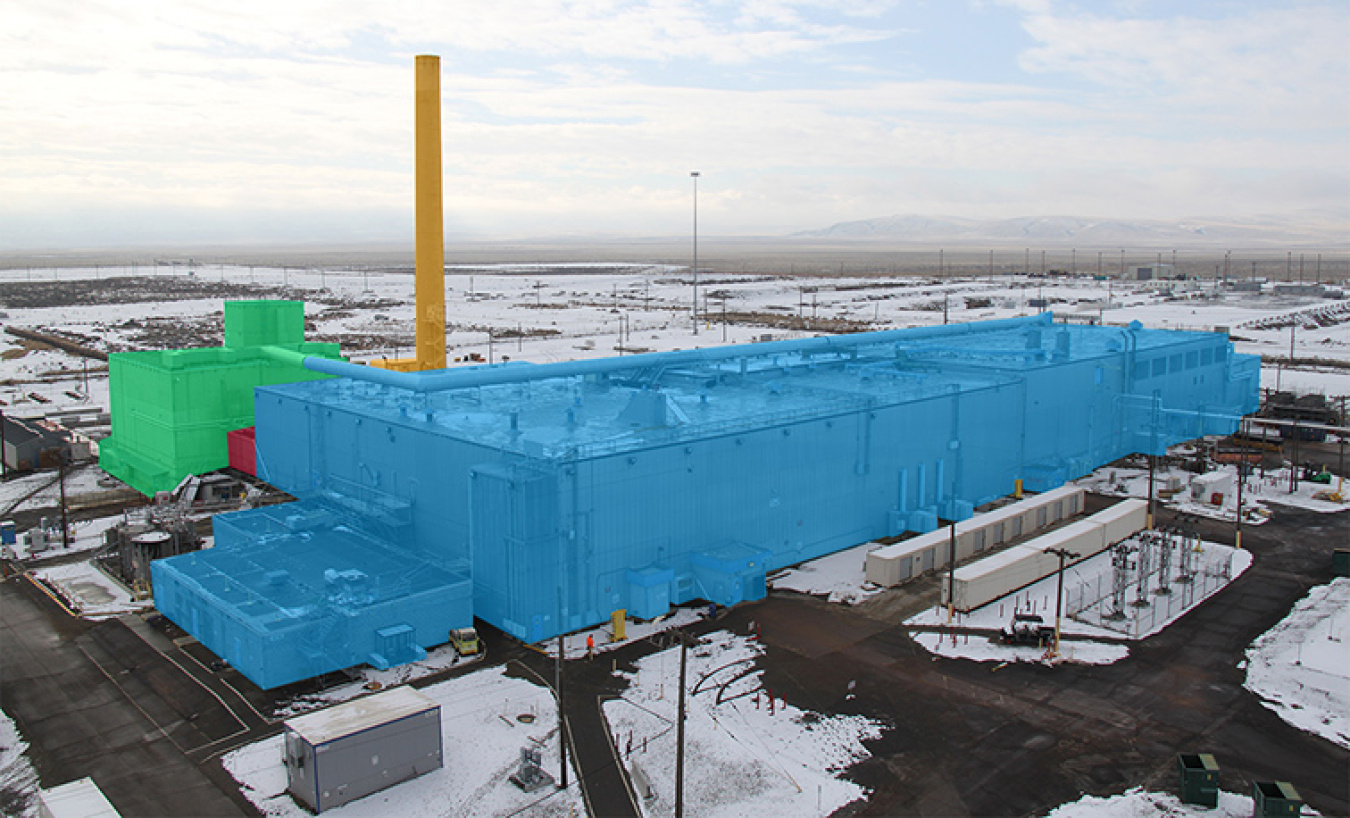

Demolition of PFP will occur in stages, as indicated in the shaded sections above. Demolition will start with the Plutonium Reclamation Facility (green), followed by 242-Z (red), the main processing building (blue), followed by the ventilation stack (orange).

PFP workers wearing specialized protective suits are cutting up and removing the largest and most heavily contaminated glove box from PFP. Since 2008, workers have removed nearly 240 similar structures.

Demolition of support structures around PFP, like this building in August 2015, is necessary to create room for demolition equipment to operate.

RICHLAND, Wash. – One of EM’s most complex risk-reduction projects is expected to wrap up in coming months as crews demolish a Cold War relic at the Hanford Site: the Plutonium Finishing Plant (PFP).

Preparing to safely demolish the facility has required contractor CH2M HILL Plateau Remediation Company (CH2M) employees to perform hazardous work, including dismantling and removing the largest and most heavily contaminated glove box. Crews are removing the last of many miles of chemical lines, tanks, and ventilation ductwork. This infrastructure supported 40 years of fabrication of plutonium metal “buttons” used in the nation’s nuclear weapons.

“The teams conducting this work continue to meet every challenge and situation with great professionalism and focus,” said Tom Teynor, project director for the EM Richland Operations Office. “We continue to view their collective work, bringing us toward demolition, as the most significant project we have this year.”

Demolition groundwork is underway as smaller support buildings are being removed to make room for demolition equipment and disposal of waste packages. EM is working with regulatory agencies and the contractor to monitor airborne hazards and weather conditions during demolition. Crews are testing procedures and systems to ensure safety of employees and the environment.

Heavy equipment will remove building components, such as glove boxes and ventilation ducts, which are too contaminated and too large to be demolished within the building. To reduce waste buildup, demolition activities will primarily occur during the daytime and waste will be loaded out at night. Dust suppression and fixatives will limit airborne hazards. Demolition is expected to take about six months, after which a protective cap will be installed over the footprint of the former structure.

“Taking down PFP will remove a significant hazard on the Hanford Site,” said Mike Swartz, CH2M vice president of the Plutonium Finishing Plant Closure Project. “Our dedicated and experienced workforce has made significant progress so far, and as we begin demolition, we will continue focusing on the fundamentals: performing our work safely and compliantly.”

“We all have the same goal: to complete demolition safely,” said Frank Hammitt, PFP radiological control technician. “I have a lot of pride in what I do, and that’s performing cleanup for my community and my kids, who will be here long after I am gone.”