EM Senior Advisor William “Ike” White has approved a proposal that will save decades of work and billions of dollars in spent nuclear fuel disposition at the Savannah River Site (SRS).

A significant software improvement is leading to enhanced decision-making on environmental cleanup at Los Alamos National Laboratory (LANL).

A subject matter expert on underground ventilation at the nation's only deep geologic repository has been recognized by the Society for Mining, Metallurgy & Exploration for his work to improve miner safety.

Following several buried waste exhumation projects in the 1970s, the DOE Idaho National Laboratory (INL) Site tested technologies to allow for a larger waste retrieval effort and attempt to minimize the spread of contaminated soil.

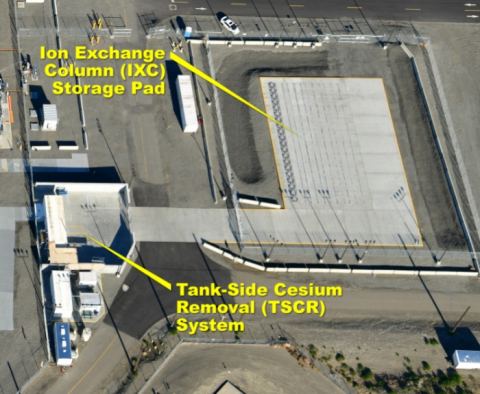

The first batch of approximately 200,000 gallons of tank waste has been treated by the Hanford Site’s Tank-Side Cesium Removal (TSCR) System and is staged in a double-shell tank for immobilization in glass.

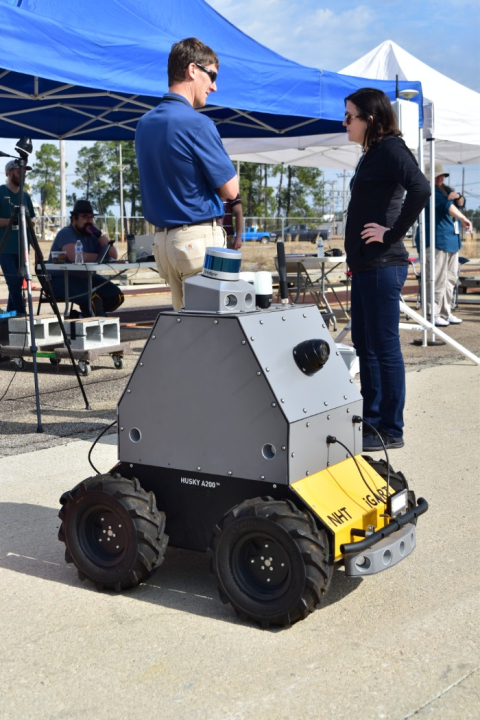

Savannah River National Laboratory (SRNL) oversaw the demonstration recently of a new radiological inspection technology called iGART.

One of the nation’s most complex environmental management challenges is detecting, monitoring and remediating contaminated groundwater.

The wheels on the bus go round and round, but soon you can see just where in town they are going.

An innovative team of truck drivers, engineers, mechanics and others has revamped trucks to make them more functional while transporting samples to support the tank waste mission at the Hanford Site.

A longstanding relationship between the United States and the United Kingdom on environmental cleanup was commemorated during the 2022 Waste Management Symposia.