An intern supporting EM at the Idaho National Laboratory Site this summer touted his hands-on experience in the field as beneficial to understanding the dynamic nature of his intended profession.

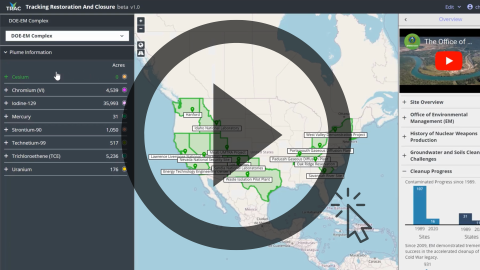

EM has developed a series of innovative initiatives to support improved groundwater monitoring and remediation across the DOE complex, including a new publicly available web-based application.

The EM Nevada Program recently completed a unique survey involving electrical energy from a controlled source and audio frequency signals to explore the geology that controls groundwater flow patterns.

Crews at the Hanford Site’s Waste Treatment and Immobilization Plant recently finished testing “bubblers,” special equipment critical to transforming radiological and chemical tank waste into a glass form for safe disposal.

Board members from the Pike County Chamber of Commerce recently visited EM’s Portsmouth Site for a tour and an update on decontamination and decommissioning (D&D) and other environmental cleanup efforts.

Workers are introducing a first at EM’s Paducah Site — use of robot technology — to set the stage for future deactivation and remediation work at the former Paducah Gaseous Diffusion Plant (PGDP).

EM Richland Operations Office (RL) contractor Central Plateau Cleanup Company (CPCCo) hosted 20 college interns and cooperative education students this summer as part of an initiative to build and inspire the future workforce.

During a visit to Hanford last week, Energy Secretary Jennifer Granholm highlighted DOE’s commitment to addressing the environmental legacy near communities such as the Tri-Cities, Washington, that supported national defense programs for many decades.

More than 100 educators, students and DOE employees gathered over two days last week for the inaugural EM Minority Serving Institutions Partnership Program (EM MSIPP) Competitive Research Awards Workshop.

EM and its cleanup contractor at the West Valley Demonstration Project (WVDP) recently overcame unique challenges and successfully finished deactivating a highly contaminated cell resembling an elevator shaft in the Main Plant Process Building.