EM Senior Advisor William “Ike” White joined leaders from the United Kingdom, Canada and France at the 2023 Waste Management Symposia to issue a joint statement today declaring their commitment to continue building their longstanding collaboration.

Addressing mercury contamination at the Y-12 National Security Complex is one of the Oak Ridge Office of Environmental Management’s (OREM) top priorities.

Founded by the National Society of Professional Engineers in 1951, National Engineers Week is dedicated to ensuring a diverse and well-educated future engineering workforce by increasing understanding of and interest in engineering and technology careers.

Three Savannah River Site (SRS) contractors recently collaborated to welcome their first joint cohort of apprentices as part of the Nuclear Fundamentals Program, which will provide over 100 trained operators to the site upon its completion.

Concrete blocks are loaded onto a metal base and transporter during tests on a gantry crane system that will lift replacement melters for the Waste Treatment and Immobilization Plant at the Hanford Site.

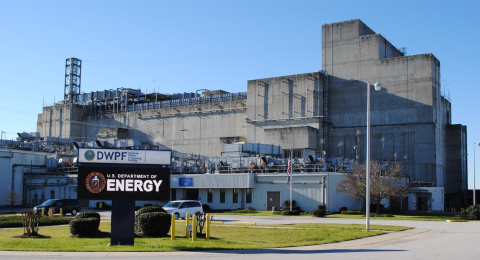

The waste vitrification facility at EM’s Savannah River Site (SRS) has completed a processing improvement enabling safer operations and more efficient conversion of high-activity liquid waste into glass.

A workshop to identify and prioritize key research and technology needs in developing long-term monitoring for groundwater contamination was held at Savannah River National Laboratory (SRNL) recently.

An aerial view of the Effluent Treatment Facility on the Hanford Site, where workers are completing the final upgrades needed for the Direct-Feed Low-Activity Waste Program to treat tank waste.

EM Richland Operations Office (RL) contractor Central Plateau Cleanup Company (CPCCo) continues to make significant progress developing the equipment, tools and techniques to safely transfer nearly 2,000 radioactive cesium and strontium capsules.

Students attending area technical colleges can now participate in the new Apprenticeship School at the Savannah River Site (SRS) created by EM contractor Savannah River Nuclear Solutions (SRNS).