June 2024

The following questions were asked by a member of the public during the ICP CAB's June 12, 2024 meeting in Fort Hall, Idaho. Answers are provided by DOE-ID staff.

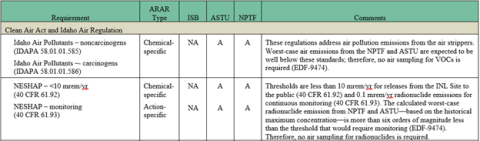

Response: New Pump and Treat Facility (NPTF) operations started in October 2001. In accordance with the Operations and Maintenance Plan for OU 1-07B TAN Groundwater Remediation (DOE/ID-11558, Table 1) no emission testing is required because the worst-case air emissions for NPTF and the Air Stripper Treatment Unit (ASTU) were determined to be well below standards for VOCs and radionuclides per an air emissions analysis performed for NPTF and ASTU (EDF-9474). The noted data from Table 1 is included below.

The return water monitoring results are reported in the Annual Report for the Final Groundwater Remediation, Test Area North, Operable Unit 1-07B. The results are included in Section 3 (PUMP and Treat) in the more recent reports. For FY 2023 the Report number is DOE/ID-12096, for FY 2022 the Report number is DOE/ID-12083, and previous report numbers can be found in the citations. These annual reports are also available on the Administrative Record/Information Repository. (ARIR Home - ARIR (idahoenvironmental.com)).

Table 1

Response: The TAN annual reports

Additionally, downgradient monitoring is performed at and around ATR, INTEC, CFA, and RWMC. Groundwater monitoring is also performed along the southern boundary of the INL as part of the OU 10-08 groundwater monitoring plan. These monitoring events are focused on the contaminants associated with the specific facility. Although monitoring for VOCs is performed at CFA, RWMC and the OU 10-08 groundwater monitoring, these are associated with facility specific concerns rather than potential migration of contaminants from TAN. As noted in the OU 10-08 monitoring plan, groundwater contaminants from TAN are not anticipated to comingle with the down gradient contaminants at other facilities. As with the TAN annual reports, all groundwater monitoring reports are available on the Administrative Record/Information Repository (ARIR Home - ARIR (idahoenvironmental.com)).

Response: The USGS water quality monitoring program at the INL has been consistently fully funded by the DOE-Idaho Operations Office over the last 25 years. Funding provided by the Department allows the the monitoring program to be consistent and effective. While USGS has sampled 429 wells on and around the INL over the period of record (1949-present), the network of wells that makeup the monitoring program has historically been 200 wells. An optimization of the monitoring network was completed in 2021 to reduce well monitoring redundancy while retaining sufficient data to reliably characterize water-quality conditions in the aquifer. This reduced USGS’s monitoring network from 200 wells to 155 wells analyzed annually. While the monitoring network may be shifting to a more efficient network presentation, the effectiveness of the program remains the same. The analysis tools and techniques USGS is employing continue to push the state-of-the-science within the USGS.

Response: No, the SEPs awarded to the Idaho Department of Water Resources allow for hydrogeologic investigation of the Snake River Plain Aquifer to achieve IDWR mission scope. The Idaho Department of Environmental Quality reviews and approves all SEPs. These SEPs met the requirements of the DEQ Policy and were determined to meet the key characteristics and categories of the Policy.

February 2024

The following questions were asked by a member of the public during the ICP CAB's February 22, 2024 meeting in Idaho Falls, Idaho. Answers are provided by DOE-ID staff.

Response: The most recent validated data set is available on the on the Administrative Record/Information Repository (ARIR Home - ARIR (idahoenvironmental.com)). Carbon tetrachloride showed a slightly increasing trend from 2017 through 2022. However, the 2023 results showed a decrease in the concentrations of carbon tetrachloride. Monitoring well M15S was the only well with a concentration exceeding the MCL (5 µg /L) with a concentration of 5.05 µg/L.

Trichloroethelyene (TCE) concentrations near RWMC remain well below the MCL (5 µg /L) and show a relatively neutral trend with the exception of well M15S. The TCE concentrations show an increasing trend at well M15S, however the concentration remains below the MCL (5 µg /L) with the reported concentration of 3.96 ug/L in FY 2023.

Response: ICP is in the process of implementing the latest DOE-STD-5506-2021, Preparation of Safety Basis Documents for Transuranic (TRU) Waste Facilities. Transuranic waste operations continue to be conducted safely and in accordance with approved nuclear safety basis documents in conformance with the previous version of the Standard, DOE-STD-5506-2007.

Response: Due to the successful completion of the buried waste retrieval effort, the SDA contains significantly less organic (combustible) matter than a municipal landfill or tire disposal area; therefore, chemical oxidation or biological decomposition is not likely to rapidly generate heat. Combustion of subsurface waste has historically not been an issue at the SDA, and the surface barrier will be constructed to add highly compacted soil over the existing SDA which will further limit oxygen influx and the potential for sustained combustion. During the development of the OU-7 13/14 Record of Decision, a scenario involving nitrate compounds rapidly decomposing to produce oxygen for combustion and creating a sustained subsurface fire beneath the evapotranspiration surface barrier was examined and was determined to be a non-credible scenario for waste buried in the SDA.

(Note this information is consistent with responses provided to questions received on the 3116 draft determination document)

Response: The assumption was made based on the level of contaminants that could be present in a residual depth of 2 in. of calcine after retrieval is complete, and past and current retrieval studies. The residual depth was chosen based on three historical, full-scale calcine retrieval tests that all yielded similar results. After the tests, the residual depth of 2 in. was determined to be a realistic assumption for performing the performance assessment calculations. More recent tests using pneumatic retrieval systems used in a full-scale mockup demonstrated effective removal of 99% of the material in the most difficult bins.

The sorption coefficients (Kd values) used in the Calcined Solids Storage Facilities Performance Assessment analysis for the radionuclides in the residual calcine are based on literature studies of radionuclide sorption in grout at the Hanford site. Grout is intended to be used in each bin and the residual is assumed to be incorporated into the grout; therefore, the controlling environment for leaching and transport of radionuclides will be the grout matrix.

Response: The documented safety analysis (DSA) for INTEC evaluates multiple (four) scenarios involving failure of the Mackay Dam. The evaluated scenarios are compliant with the methods described 10 CFR 830 and applicable DOE Orders.

Hazardous Waste Management Act/Resource Conservation and Recovery Act (HWMA/RCRA) does not have requirements for assessing the probability of an upstream dam failure. Both INL site contractors have a Documented Safety Analysis (DSA) to provide safety analysis methodologies and information required for and common to all facilities operated at the INL site that are subject to the requirements of Title 10 Code of Federal Regulations (CFR) Part 830, Subpart B, “Safety Basis Requirements.” The DSA includes flooding from natural phenomena and flooding from Mackay Dam failure. The models indicate the current flood controls adequately mitigate flood water away from INL site facilities.

HWMA/RCRA requires floodplain requirements be applied to the permit if a facility is located within the 100-year floodplain. None of the facilities at RWMC/AMWTP are in the 100-year floodplain. There are two buildings at INTEC within the 100-year floodplain: Buildings T-1 and T-5. The INL Site Diversion Dam was constructed in 1958 to divert high run-off flows from downstream facilities. The diversion dam consists of a small earthen dam and head gate that diverts water from the main channel, through a connecting channel, and into a series of four natural depressions called spreading areas. The INL Site Diversion Dam has sufficient capacity to mitigate water from the 100-year flood from the Big Lost River and the potential failure of Mackay Dam away from INL site facilities. In addition, to ensure that all potential sources of flooding were evaluated for INTEC facilities, the report “100-Year Storm Water Runoff Floodplain and 25-Year Runoff Analyses for the Idaho Nuclear Technology and Engineering Center at the Idaho National Engineering and Environmental Laboratory” (INEEL/EXT-03-01174, Revision 3, January 2004) was prepared. This study evaluated the largest 25-year and 100-year storm water flood flows through and in the vicinity of INTEC and determined no flooding impacts to RCRA buildings at INTEC. INTEC is surrounded by a perimeter road and ditch system, which serves as a major drainage divide around the facility. Storm water run-off from within INTEC is controlled by a network of channels and culverts that drain to a storm water basin outside the facility. These physical barriers provide flood protection for the HWMA/RCRA unit partially in the 100-year floodplain.

Response: The IWTU has a stack emissions sampling system installed that is online during plant waste treatment operations which complies with NESHAP (40 CFR 61.93 [c]) and conforms to the ANSI 99 standards. The sample data is reported annually to DOE by the operating contractor and included in the Idaho National Laboratory (INL) National Emission Standards for Hazardous Air Pollutants (NESHAP) Annual Report for Radionuclides.

April 2023

The following questions were asked by a member of the public during the ICP CAB's April 27, 2023 meeting in Idaho Falls, Idaho. Answers are provided by DOE-ID staff.

Answer: The cap depth for the Idaho CERCLA Disposal Facility (ICDF) must comply with DOE Order 435.1 requirements for a 10ft cover thickness on top of waste.

Answer: The Defense Nuclear Facilities Safety Board (DNFSB) is chartered by Congress to provide DOE oversight. DNFSB oversight results are reported to Congress. Periodic DNFSB oversight reports are published on the DNFSB website. DOE-ICP has no current safety issues with the DNFSB.

Answer: Decontamination and decommissioning (D&D) is based on mission completion and available funding. Most infrastructure on the INL is identified under the General Action Memorandum for D&D, however D&D cannot occur until missions are completed and funding identified. Until D&D begins, infrastructure is maintained in a manner protective of human health and the environment.

Question: Please explain the recent Occurrence Reporting and Processing System (ORPS) report regarding radiological issues. What facility, why did this meet ORPS criteria? What happened in order for an ORPS reportable event, at unidentified Idaho Cleanup Project, to be ORPS reportable and apparently related to a radiological event? What radionuclides were involved?

Answer:

It is believed that the occurrence report referenced above is EM-ID--IEC-RWMC-2023-0001, Contamination Found on Boot While Exiting ARP 2 Enclosure.

On February 6, 2023, personnel entered the Accelerated Retrieval Project waste exhumation facility (ARP-II), with appropriate PPE. After exiting and doffing their PPE, an operator stepped into a personnel contamination monitor which alerted the presence of contamination on their personal boot. The boot was taken and bagged. Surveys indicated 30,000 DPM/100 cm2 total contamination. The isotopes were Pu-239 and Am-241.

DOE Occurrence Reports and reporting criteria can be found in DOE O 232.2A CHG 1, Occurrence Reporting and Processing of Operations Information. The contamination discovered on the operator’s boot met the minimum reporting criteria of Group 6D(3), which stated:

Identification of onsite personnel or clothing contamination (excluding anti contamination clothing provided by the site for radiological protection) that exceeds 10 times the total contamination values identified in 10 CFR Part 835, Appendix D. The contamination level must be based on direct measurement and not averaged over any area. This criterion does not apply to tritium contamination.

To view DOE Orders, go to https://www.directives.doe.gov/.

To view DOE Occurrence Reports, go to https://www.energy.gov/ehss/policy-guidance-reports/dashboards.

Answer: Due to a transition in support staff for the ICP CAB, there was a period of time where the website was not being updated as the necessary security clearances and website access permissions were obtained. Minutes are now being posted within 45 days of meeting dates.

Question: Why isn’t the Mackay dam failure and flood of INL (Idaho Nuclear Technology and Engineering Center (INTEC), etc.) Included in Resource Conservation and Recovery Act (RCRA) permits, especially for INTEC as it is now more likely than a 1-in-100 year event?

Answer: Hazardous Waste Management Act (HWMA)/RCRA requires floodplain requirements be applied to the permit if a facility is located within the 100-year floodplain. At INTEC, a portion of the facility area was shown to be within the 100-year floodplain, and a rationale was provided regarding the presence of drainage and flood control barriers. The portion of INTEC shown to be in the 100-year floodplain, includes information about physical barriers providing flood protection for that HWMA/RCRA unit. Specifically, information about the INL Site Diversion Dam, which was constructed in 1958 to divert high run-off flows away from downstream facilities. The diversion dam consists of a small earthen dam and head gate that diverts water from the main channel, through a connecting channel, and into a series of four natural depressions called spreading areas. The INL Site Diversion Dam has sufficient capacity to mitigate water from the 100-year flood from the Big Lost River and the potential failure of Mackay Dam away from INL and ICP facilities.

HWMA/RCRA does not have requirements for assessing the probability of an upstream dam failure. INL and ICP each have a Documented Safety Analysis (DSA) to provide safety analysis methodologies and information required for and common to all facilities operated by ICP or INL that are subject to the requirements of Title 10 Code of Federal Regulations (CFR) Part 830, Subpart B, “Safety Basis Requirements.” The DSA includes flooding from natural phenomena and flooding from Mackay Dam failure. DOE does not estimate the probability of the Mackay Dam failure from a structural integrity perspective as the hydrologic consequences would be unchanged. DOE does estimate flooding inundation potential (i.e., hydrologic consequences) based on various modeled scenarios of the Mackay Dam failing.

June 2019

The following question was asked by a member of the public during the ICP CAB's June 20, 2019 meeting in Fort Hall, Idaho. The answer is provided by DOE-ID staff.

Answer: The performance objective for targeted waste retrieval was established in a record of decision agreed to by the regulators that states: “Completion of targeted waste retrieval will be measured by the volume of targeted waste retrieved. A minimum volume of targeted waste of 6,238 m3 will be retrieved from a minimum of 5.69 acres…, with the need for additional retrievals, if necessary, determined pursuant to CERCLA.” Therefore, the performance objective is based on the volume of targeted waste removed, not the removal of Am-241 curies from the SDA.

April 2019

The following questions were asked by a member of the public during the ICP CAB's April 25, 2019 meeting in Twin Falls, Idaho. Answers are provided by DOE-ID staff.

Answer: The Resource Conservation and Recovery Act (RCRA) permit requires that the IWTU be “continuously monitored.” Attachment 1, Section D of the permit states that continuous monitoring of CO and O2 with a Continuous Emissions Monitoring System (CEMS) is used. The permit states that if CO concentrations using the two CEMS measurements from A-H-941-3A and A-H-941-3B are above or equal to 100 parts per million on an hourly rolling average, then an Automatic Waste Feed Cutoff actuates.

The air permit states that we shall comply with the requirements specified in 40 CFR 61, Subpart H and that emissions of radionuclides to the ambient air from DOE facilities shall not exceed those amounts that would cause any member of the public to receive, in a year, an effective dose of 10 millirem per year. Compliance with 40 CFR 61, Subpart H is accomplished by in-line stack sampling for radionuclide emissions from a particulate filter and activated charcoal filter, referred to as the Radionuclide Monitoring System (RMS). The particulate filter is analyzed using an approved EPA method (Method 114) for Gamma emitters (Cs-137, Ba-137m), total Sr-90, and Actinides (Am-241, Pu-238, Pu-239/240). The activated charcoal filter will also be analyzed using an approved EPA test method (Method 114) and will be analyzed for I-129.

The frequency for sampling the RMS is outlined in the document, “Quality Assurance Project Plan for the IWTU STK-SRE-140 Radiological Emissions Sampling System.” The particulate filter will be sampled once per week for the first four weeks of operation, then monthly for the remainder of the project. The activated charcoal filter is sampled quarterly for the entirety of the project. All sample data from the RMS is used to comply with the reporting requirements of 40 CFR 61.93.

Answer: There was no explosion during the April 11, 2018 event at the Accelerated Retrieval Project V facility, nor was hydrogen a contributing factor. The event was caused by the heating of unoxidized uranium that led to the hydrolysis reaction of beryllium carbide that resulted in rapid methane gas generation of sufficient pressure to overcome the drum lids.

Following the event and after extensive modeling, chemical compatibility reviews, and operating experience integration, new controls were established to monitor and prevent recurrence of these reactions. Procedures now require that workers rake through the waste material and hold it for a 24-hour period and perform thermal monitoring to look for elevated temperatures indicative of an on-going reaction. Jensen Hughes, a nationally recognized fire science consulting company, reviewed the controls to ensure they mitigate the risk and meet acceptable industry standards and practices. While the ARP V event involved pressurization, Jensen Hughes also looked more broadly at approaches for dealing with drums that may exceed the Lower Flammability Limit and concluded that they are sound and consistent with industry practice.

Beginning in September 2018, Fluor Idaho implemented the new controls for exhumed waste at the Accelerated Retrieval Project VIII facility (which has since been completed). Since then, the process has been employed on waste in the Accelerated Retrieval Project V facility, and currently in the Accelerated Retrieval Project IX facility. There have been no further adverse incidents.

Answer: The Idaho Department of Environmental Quality determined that the Integrated Waste Treatment Unit does not meet the definition of a hazardous waste combustor under federal regulations, and therefore direct regulation of the steam reformer emissions is not applicable. Performance testing of the system will be required, and DEQ will set the emission rates that are protective of human health and the environment. Additional emissions parameters, if found necessary after the performance test, could be established in the permit.

Answer: The hydrogen and methane gas presence in waste drums is a known phenomenon. Flammable gases may exist based on many sources, including petroleum products in certain waste, and such waste is monitored and controlled in accordance with regulations (such as RCRA, for example, when applicable) and facility permits as well as operational and worker safety limits.

DOE is taking action to ensure that lessons learned from this event are shared and understood. A Safety Alert was prepared and sent to EM waste sites to inform the EM complex of the potential vulnerability. In addition, an Occurrence Reporting and Processing System (ORPS) report was issued on the April 11, 2018 drum event at the Advanced Retrieval Project (ARP) V facility.

Answer: We have 155 drums of TRU waste that still need additional work to meet the WIPP Waste Acceptance Criteria due to issues associated with flammable gas testing. These containers are stored in a number of locations such as the WMF- 636, Transuranic Storage Area- Retrieval Enclosure, or a Type II Storage Module (e.g., WMF-629, 630, 631, 632, or 633). They are tracked in the Waste Tracking System and are inspected per the RCRA permit requirements.

February 2019

The following questions were asked by a member of the public during the ICP CAB's February 21, 2019 meeting in Idaho Falls, Idaho. Answers are provided by DOE-ID staff.

Question: I cannot find documentation pertaining to the acceptance by the U.S. NRC of DOE-ID's proposed Waste Incidental to Reprocessing determination for the bulk of the sodium-bearing waste, other than NRC's agreement that criterion 1 was satisfied (no need for radionuclide separations). The NRC's acceptance of residual tank cleanout issues are not the same analysis as the reclassification of the bulk of the SBW. I do not find documented support for the assertions made that the NRC was in agreement with DOE's reclassification of the bulk of the SBW. Please advise me the specific documents I need to review.

The NRC review focused on the first criterion under the DOE Order 435.1 Waste Incidental to Reprocessing (WIR) process: “The waste must have been processed, or will be processed, to remove key radionuclides to the maximum extent that is technically and economically practical.” NRC concluded that it is not technically or economically practical to remove additional key radionuclides from the SBW prior to disposal; this conclusion applies to the bulk of the SBW and is not limited to residual materials. In the NRC’s recommendation for the first criterion they state, “residual uncertainty is not expected to … invalidate DOE-ID’s conclusion that SBW . . . can be managed as TRU waste.”

The other two criteria in DOE Order 435.1 WIR process pertain to waste classification and disposition requirements. The NRC did not explicitly evaluate these criteria—regarding classification of SBW as transuranic waste and disposal at the Waste Isolation Pilot Plant (WIPP)—because they determined that doing so would be inappropriate and outside NRC’s jurisdiction given that NRC’s WIR guidance does not include a TRU disposal option and the WIPP’s long-term performance is regulated by the Environmental Protection Agency.

At this time, DOE has not made a decision related to the final classification and disposition of the SBW.

Question: ICP Progress presentation for Feb 21 stated "CPP-749 Degradation." It is an underground fuel storage facility. I cannot find any information about the degradation and no information was provided to the ICP CAB. Can you please explain the degradation to the spent nuclear fuel storage facility?

Answer: The Underground Fuel Storage Facility, (UFSF), CPP-749, is located at the Idaho Nuclear Technology and Engineering Center (INTEC) within the Idaho National Laboratory site (INL). It is comprised of two engineered fuel storage areas referred to as the first generation (1st gen) and second generation (2nd gen) vaults. The 1st gen vaults were placed into operation in September of 1971, and the 2nd gen vaults were placed into operation in December of 1984.

Despite the careful engineering inherent in the design of the 1st gen vaults, small amounts of water have been observed within these vaults. The water gained access through either seepage or condensation. While the fuel is containerized, it is not desirable to have fuel stored with water over the long term. This can result in hydrogen generation and structural degradation. As a result, fuel contained within the 1st gen vaults will be transferred to the more robust 2nd gen vaults where water has never been observed. Phase 1 activities (sampling, HEPA venting, and preparation of a cost estimate) are complete. Phase 2 (fuel transfers) will begin when funds are secured.

The degradation issue was discussed during a Citizens Advisory Board meeting in Sun Valley in October, 2018. After that meeting, we also received a question from a member of the public and responded with the following answer, which has also been posted immediately below:

Question from October 2018: Are the problems at CPP-749 related to the fire water leak that caused some flooding of the wells many years ago?

Answer from October 2018: Not directly. We’d been aware of degradation in the CPP-749 wells for some time prior to the fire water leak. In 1997, our contractor made five fuel transfers out of the CPP-749 dry wells to begin dealing with the situation. When we received authorization to construct a spent fuel packaging facility, fuel transfers were put on hold to avoid handling the fuel more than necessary. However, the spent fuel packaging facility was later cancelled. We are now in the process of addressing the problem by improving the ventilation of the dry wells, and making plans to eventually remove the fuel from the first generation vaults where the problem is focused.

October 25, 2018

The following question was asked by a member of the public during the ICP CAB's October 25, 2018 meeting in Sun Valley, Idaho. The answer to the question is provided by DOE-ID staff.

Answer: Not directly. We’d been aware of degradation in the CPP-749 wells for some time prior to the fire water leak. In 1997, our contractor made five fuel transfers out of the CPP-749 dry wells to begin dealing with the situation. When we received authorization to construct a spent fuel packaging facility, fuel transfers were put on hold to avoid handling the fuel more than necessary. However, the spent fuel packaging facility was later cancelled. We are now in the process of addressing the problem by improving the ventilation of the dry wells, and making plans to eventually remove the fuel from the first generation vaults where the problem is focused.

February 21, 2018

The following questions were submitted via question cards by a member of the public during the ICP CAB's February 21, 2018 meeting in Idaho Falls. Answers to the questions are provided by DOE-ID staff.

Answer: DOE signed a Record of Decision in the mid-1990s to consolidate fuels with similar cladding at specific sites. DOE has not decided to fully implement this decision at this time.

Answer: The well was located next to CPP-666. It was used to dispose of service wastewater, which consisted primarily of plant cooling water, demineralizer and boiler blowdown water, and condensates from the Process Equipment Waste Evaporator (PEWE). The well was fed from the PEWE building. It was used from 1950 to 1984, and was officially closed in 1989.

Answer: DOE is prepared to provide the CAB with information about what studies have been done on calcine storage facilities if requested.

Answer: The DOE analysis of AMWTP continuing mission is not complete. DOE is refining its analyses to assess the challenges, cost-effectiveness and viability of a continuing mission for AMWTP.

Answer: INL/ICP carbon tetrachloride releases to air are well below levels that require ambient air monitoring at the INL Site, Idaho Falls, or other locations.