A team at the Waste Treatment and Immobilization Plant (WTP) at the Hanford Site recently tested the plant’s autosampling system, capping off an effort to address technical challenges affecting system reliability.

Office of Environmental Management

May 23, 2023

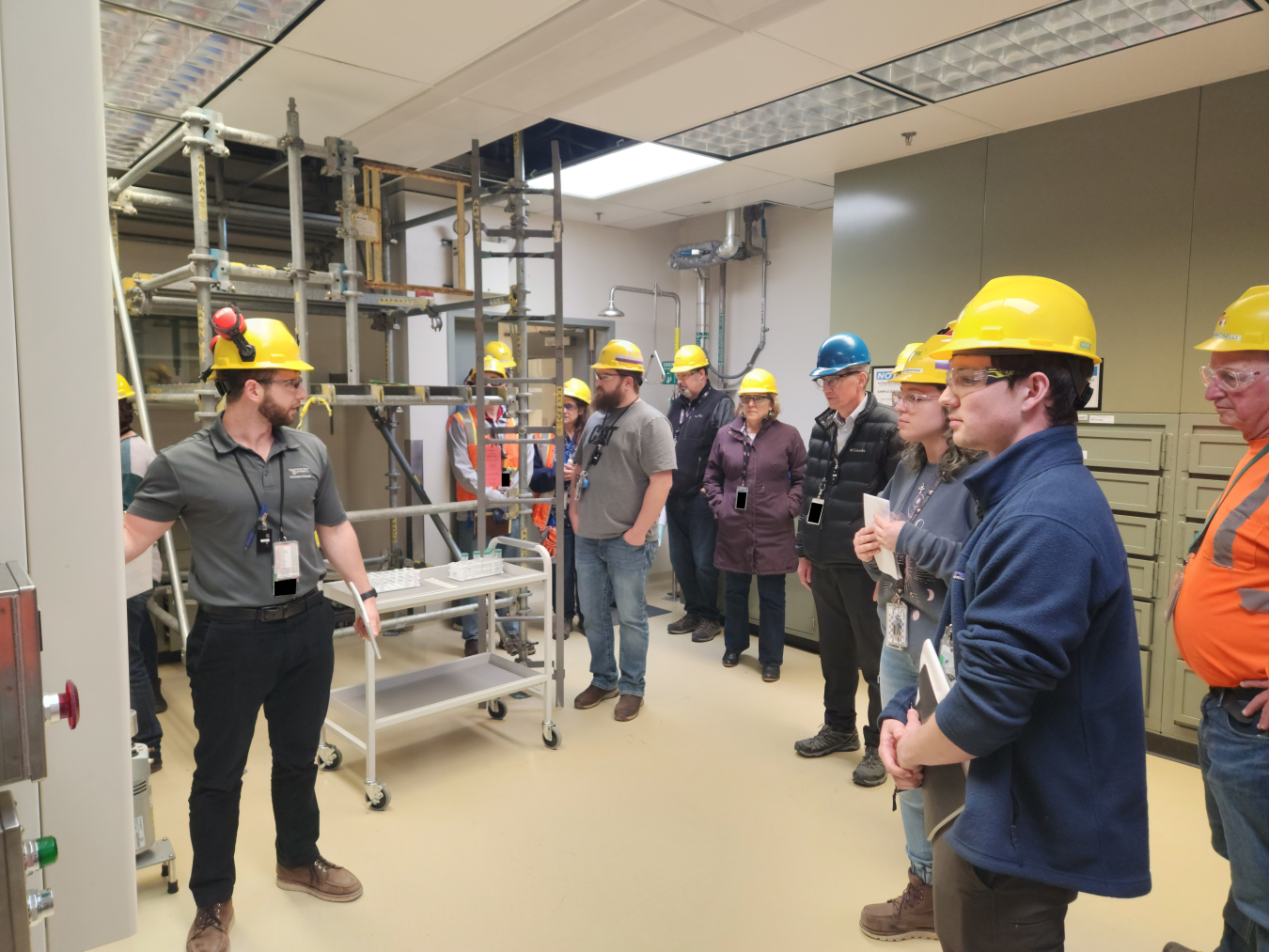

Waste Treatment and Immobilization Plant Shift Operations Supervisor Gent Ferati, left, gives EM Office of River Protection and Richland Operations Office Manager Brian Vance, fourth from right, an update on the status of an autosampling system at the plant.

RICHLAND, Wash. – A team at the Waste Treatment and Immobilization Plant (WTP) at the Hanford Site recently tested the plant’s autosampling system, capping off an effort to address technical challenges affecting system reliability.

The system will automatically collect samples of radioactive waste from the WTP’s Low-Activity Waste (LAW) Facility tanks at various stages throughout the waste treatment process, reducing potential human error in the sampling process.

Treated waste from Hanford’s underground storage tanks will be fed directly to melters inside the LAW Facility. The waste will be mixed with glass-forming materials and heated in a process known as vitrification, which immobilizes it in glass. The mixture will then be poured into stainless-steel containers for disposal at the Integrated Disposal Facility at Hanford.

“The autosampling system is a critically important part of future operations,” said Tom Fletcher, EM assistant manager and federal project director for the WTP Project. “It will deliver samples to lab chemists and technicians, who will analyze the samples to confirm the correct combination of glass-forming materials needed to mix with the waste during vitrification. This step ensures the plant produces a compliant glass form that meets all regulatory requirements for disposal at Hanford’s Integrated Disposal Facility.”

During testing, the autosampling system collected samples of water used to simulate waste ready for treatment from the LAW Facility, and transferred them to the plant’s Analytical Laboratory. The system completed the sampling process with no input or intervention required by an operator, demonstrating its ability to perform as designed.

During the waste treatment process, the samples will be packaged and transferred to the Analytical Laboratory through tubes using pressurized air, similar to the tube system at a bank drive-thru.

“We assembled a cross-functional group of craft professionals and engineers to tackle any system technical challenges,” said Rick Holmes, general manager for Waste Treatment Completion Company, a subcontractor to Bechtel National Inc., which is designing, building and commissioning the WTP for EM’s Office of River Protection. “In this case, they attacked the challenges head-on as one team, and as a result the system is ready for the next steps towards operations.”

To receive the latest news and updates about the Office of Environmental Management, submit your e-mail address.