Oak Ridge Office of Environmental Management contractor Isotek Systems found savings of more than $10,000 annually thanks to the initiative and questioning attitude of its employees. June 17, 2025.

Office of Environmental Management

June 17, 2025Isotek Waste Management Specialist Shane Kilby, right, provides guidance for an upcoming waste shipment at Oak Ridge.

OAK RIDGE, Tenn. – Oak Ridge Office of Environmental Management (OREM) contractor Isotek Systems found savings of more than $10,000 annually thanks to the initiative and questioning attitude of its employees.

Isotek leads OREM’s highest priority cleanup project at Oak Ridge National Laboratory, which involves processing and disposing of the nation’s inventory of uranium (U)-233 stored in the world’s oldest operating nuclear facility.

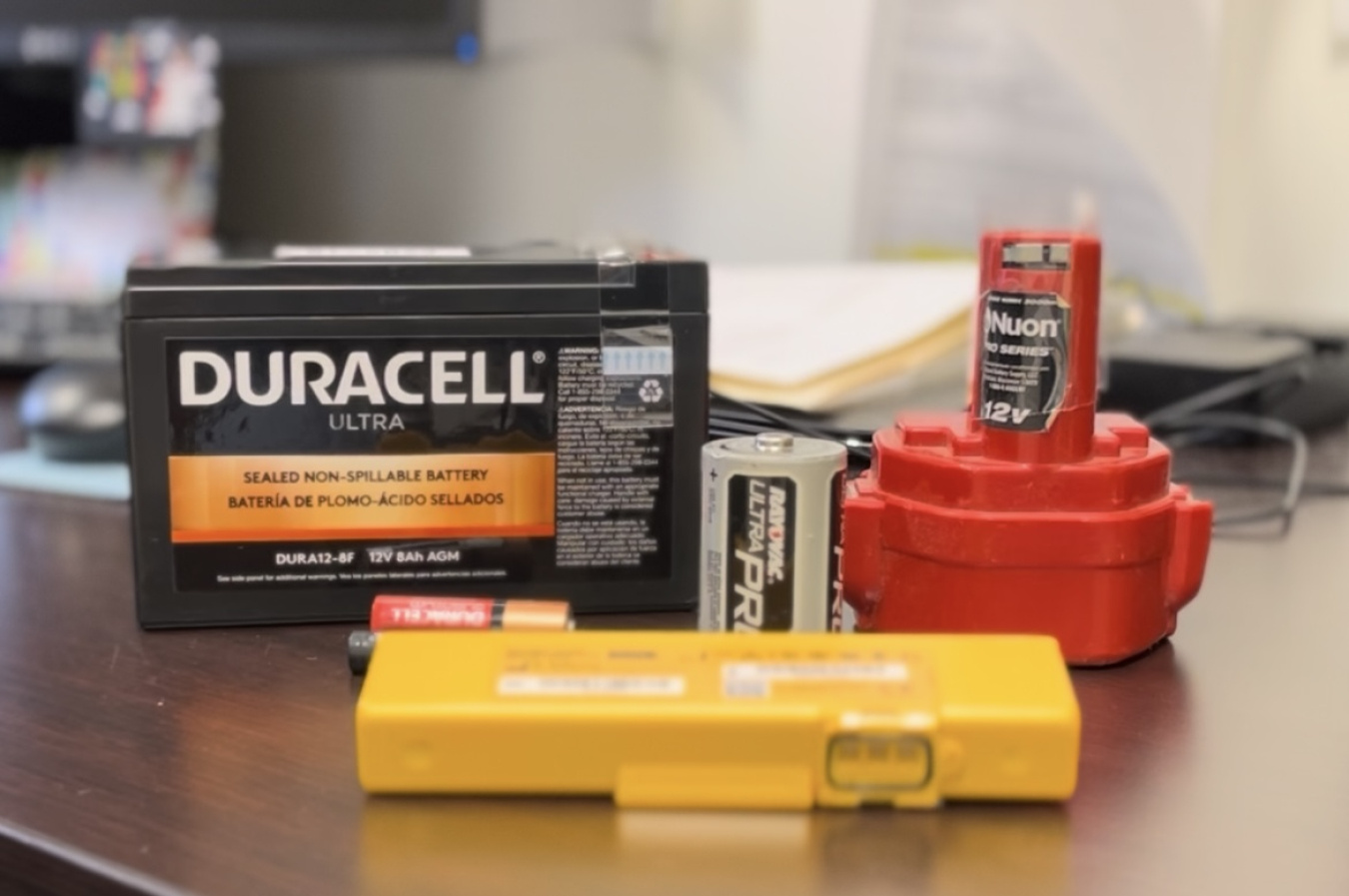

Processing this material not only generates U-233-related waste, but the contractor’s operations also create a wide variety of other waste streams that take time and money for disposal. One of the waste streams generated by operations is used batteries — and lots of them.

“We go through a few hundred batteries every year,” said Shane Kilby, Isotek waste management specialist. “Some of them, like the lead acid batteries, need special handling to properly dispose of, so it can cost a lot of money.”

Isotek’s operations at Oak Ridge require the use and disposal of a wide variety of batteries. A revised approach for their disposal is avoiding more than $10,000 in costs annually.

Using his previous experience as a supervisor at a recycling plant, Kilby believed there could be a more affordable solution for recycling lead batteries than subcontracting a company to pick up large containers of the batteries for recycling. The lead acid batteries are similar to those found in cars.

He did the research and found a local company that not only takes lead acid batteries but also pays for them. Instead of incurring $10,000 in costs annually, Isotek is now receiving funds from battery removal.

“I applaud Shane’s questioning attitude,” said John Garrity, Isotek deputy project manager. “Isotek has a lot of really innovative people on this project, and it’s because of them that we are able to continually improve.”

Isotek’s operations at Oak Ridge National Laboratory generate several waste streams. The primary waste stream is processed and downblended uranium-233 material that is disposed of offsite. That material is pictured being loaded for shipment.

Isotek is also saving money disposing of alkaline batteries. Tabatha Montgomery, Isotek waste management database administrator, researched different recycling services for other kinds of batteries.

“I found that we could save a significant amount of money if we used different packaging and shipped the batteries ourselves rather than having a contractor come pick them up,” she said.

The prior method of disposing of alkaline batteries cost around $3,000 per year, but the recent change reduces that cost to only $400 annually.

-Contributor: John Gray

To receive the latest news and updates about the Office of Environmental Management, submit your e-mail address.