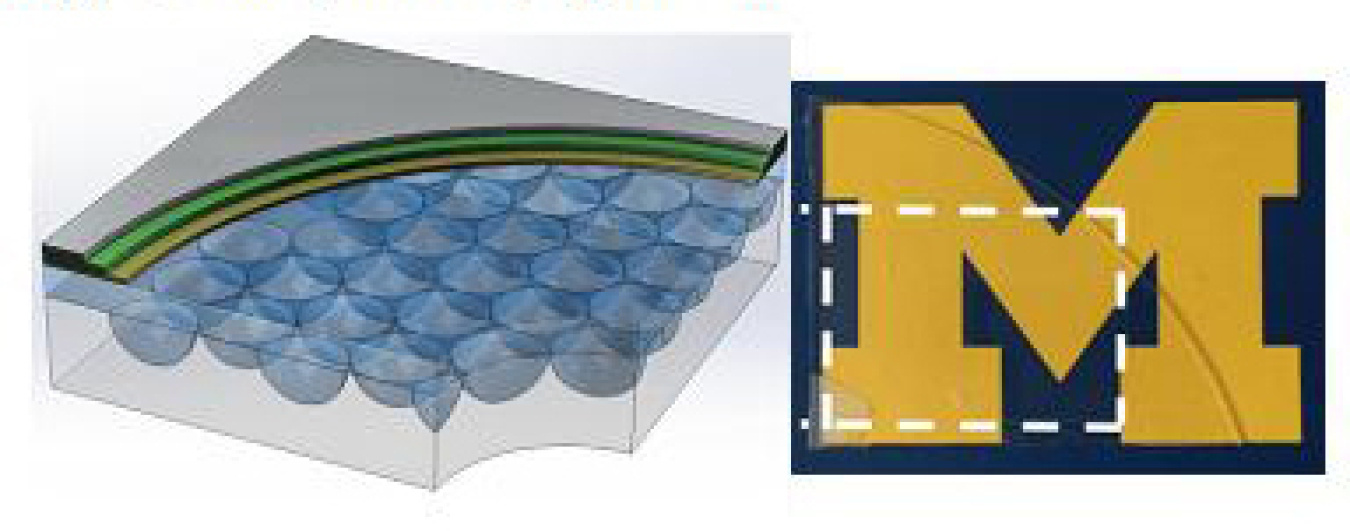

Embedding a microlens array between the transparent bottom electrode and glass substrate can efficiently extract trapped light. The SEMLA structure (dashed lines) on a printed background has no apparent impact on the image sharpness.

With the help of DOE funding, researchers at the University of Michigan have developed a method to increase the light extraction in white organic light-emitting diodes (OLEDs), thereby improving their performance and reducing their cost. Based on a sub-electrode microlens array (SEMLA), the method has increased the external quantum efficiency (EQE, the ratio of photons emitted from an OLED to the electrons injected from the electrodes) of electrophosphorescent white-emitting OLEDs (WOLEDs) to 70% – a significant improvement over past results.

The SEMLA comprises a high-refractive-index microlens array that’s located between the OLED’s glass substrate and transparent electrode, with a flat surface to support the OLED’s active region. This high-index medium extracts trapped optical power into the substrate, preventing the loss of that power in the nearby absorptive electrodes.

The SEMLA demonstrates wavelength and angle independence, providing the same enhancement for monochromatic green OLEDs and WOLEDs. Since it has no effect on the image resolution, it is compatible with both display and lighting applications. The SEMLA is also separated from the WOLED active region and thus does not impact the diode’s electrical characteristics. And due to the SEMLA’s micron-scale size, it can easily be achieved using conventional photolithography prior to the OLED array deposition, and thus is compatible with large-scale, low-cost manufacturing.

Taken together, the SEMLA offers the highest combination of high extraction efficiency and potentially low cost of any light-extraction technology yet introduced. The technology is licensed for commercialization to U.S. OLED manufacturer Universal Display Corp. and is being explored for adoption by U.S. OLED lighting manufacturer OLEDWorks. (July 2019)

Return to Research Highlights.