Diffuse lighting sources such as organic LEDs (OLEDs) offer a thin, flexible, efficient, glare-free option for luminaire design. Though OLED lighting panels have been available commercially for several years, there has been relatively slow adoption into commercial and consumer fixtures in the U.S. Even with panel cost reductions and performance and lifetime improvements, slow market adoption persists, partly due to a lack of innovative products available. In this DOE-funded project, OLEDWorks addresses this barrier by creating ultra-thin, bendable, high-efficiency OLED light engines that incorporate a panel and a driver in one low-cost unit, to encourage luminaire makers to produce innovative luminaires and increase the number of OLED fixtures available to lighting designers and specifiers.

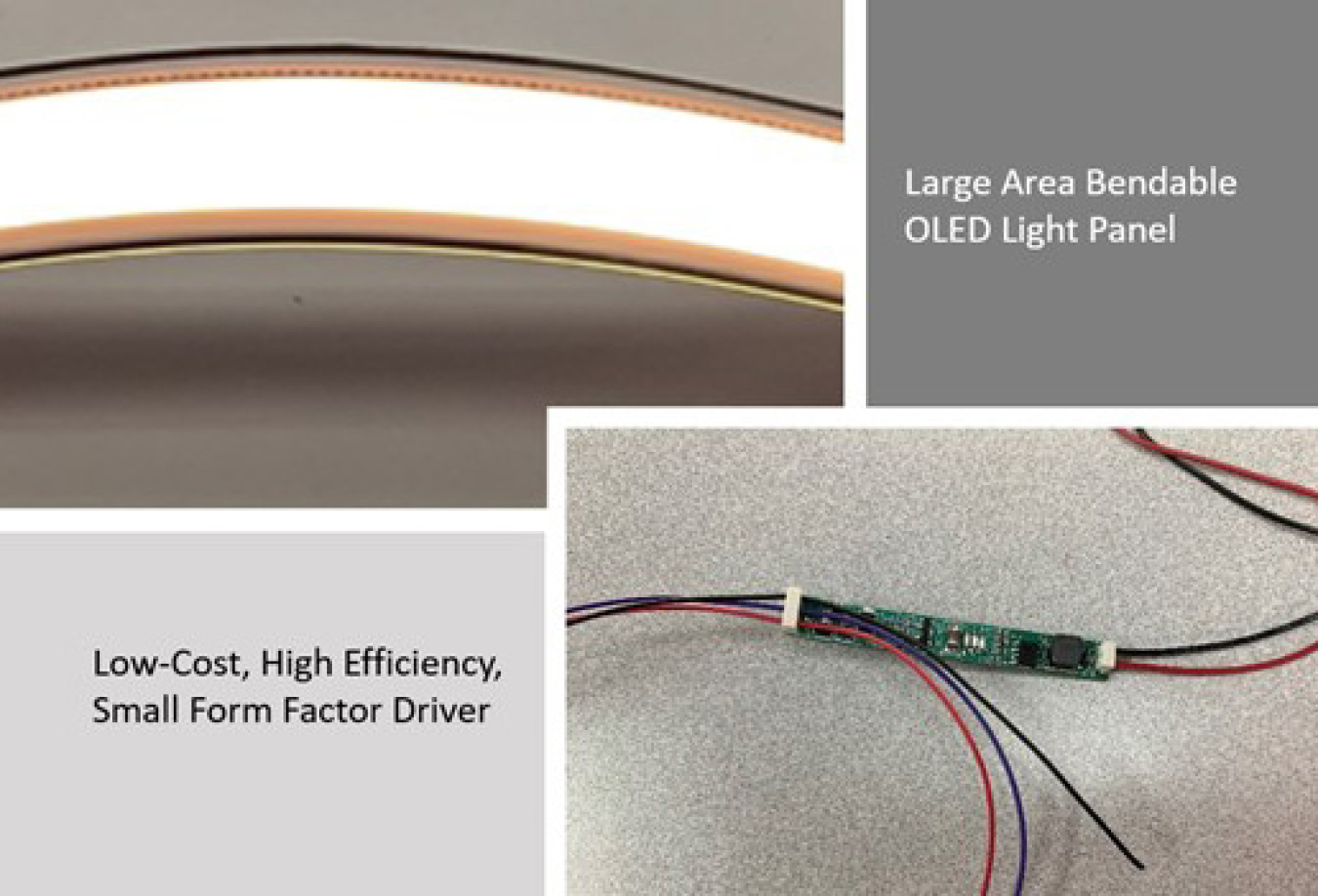

Specifically, OLEDWorks combined high-efficacy, bendable, large-area (>150 cm2) OLED light panels with one-time bendable sub-assemblies and low-cost drivers into one easy-to-use light engine. The panels were achieved by co-optimizing printable internal light extraction on ultra-thin, bendable glass and hybrid OLED formulations combining blue fluorescent and red and green phosphorescent emitters. One-time bendable sub-assemblies were achieved by co-optimizing vacuum formed plastic top and bottom housing parts with an aluminum stiffener and a flexible printed circuit board. Finally, a low-cost, high-efficiency, small form factor (long and thin) driver was developed for use within the wiring architecture of luminaires, rather than within the light engine itself.

OLEDWorks has successfully demonstrated bendable OLED light panel devices with an efficacy of 89 lm/W and a lifetime >100,000 hours. Further, they achieved large area (>300 cm2) OLED light panels by reducing the frequency of “hot spots” that lead to shorting and low yield for large OLED light panels. Technology to reduce hot spots in OLED light panels can have a significant impact on OLED light panel yield and cost across all types (rigid and bendable, general lighting and automotive, segmented and non-segmented) of OLED products.

The team also explored hybrid polymer/aluminum sub-assemblies with flexible electrical-contacting technology. Though further work is needed to implement these sub-assemblies into OLED light engine products, once the bendable OLED light panels are ready for cost-effective manufacturing, the flexible electrical-contacting technology has potential application on current rigid OLED light panels as a potential cost reduction technology.

Finally, OLEDWorks has demonstrated low-cost, high-efficiency, small form factor drivers that have been commercialized and both sampled and sold to luminaire manufacturers. This is a key accomplishment, as the poor availability of low-cost OLED drivers that match the ultra-thin, light form factor of rigid OLED light panels has been a significant barrier to OLED lighting adoption. (September 2021)

Return to Research Highlights.