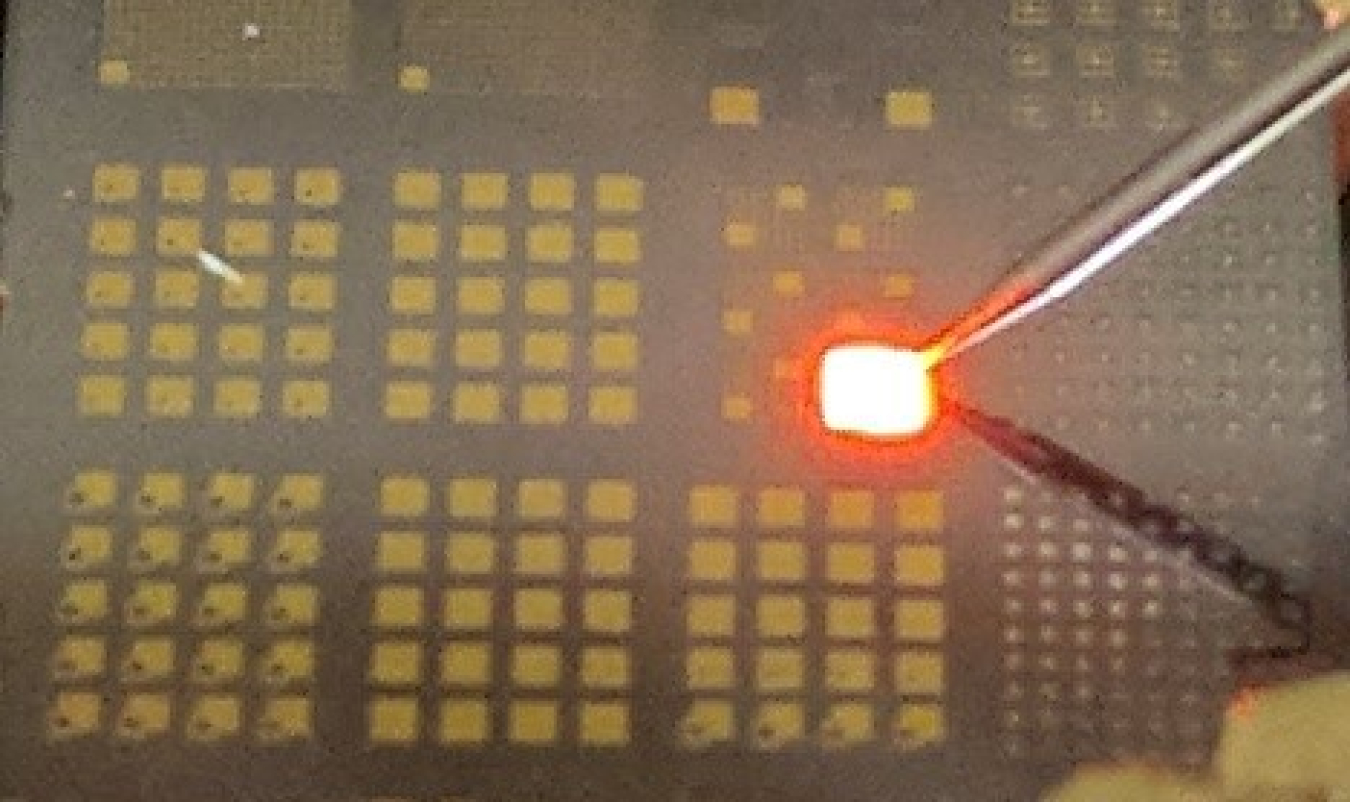

Light emission from an unpackaged AlInP LED on substrate.

Most mass-produced red and amber light-emitting diodes (LEDs) on the market today are based on the elements aluminum, gallium, indium, and phosphide (abbreviated as AlGaInP when used in combination). The efficiency of these AlGaInP LEDs is limited by the loss of injected electrons through several pathways that are intrinsic to that kind of material system. With funding from the U.S. Department of Energy (DOE), researchers at the National Renewable Energy Laboratory (NREL), MicroLink Devices, and the South Dakota School of Mines and Technology have demonstrated that these pathways, and the losses they entail, can be reduced by switching to a related material system that’s based on aluminum, indium, and phosphide (AlInP). This new approach has the potential to enable improvements in amber (~580-590 nm) and red (~610-620 nm) LED efficiencies.

The emission wavelength of AlGaInP can be tuned from red to amber by replacing some of the gallium atoms with aluminum. However, this replacement lowers the barrier for electrons to populate energy states that have much lower radiative recombination rates. It also lowers the energetic barriers to electrons passing over cladding layers meant to keep those electrons in the light-emitting layers. These two barriers are linked to the fundamental AlGaInP material properties and are primarily responsible for the low efficiencies of amber LEDs.

The research team is exploring how these barriers change when substituting AlInP for AGaInP. Both energetic barriers can be increased in alloys emitting at 590 nm to over 130 meV by tailoring the AlInP composition and the aluminum and indium atomic arrangement in the crystal. A particular advantage of this approach is that very similar material compositions can be used for all layers of the LED, which may help to simplify device growth and reduce defects at the interfaces between layers.

This research advances our understanding of the AlInP material system and its potential to support substantial improvements in amber and red LED efficiency. They now form the basis for the next steps in the project, which will involve demonstrating devices with improved performance. Such approaches to overcoming the electron losses in AlGaInP are necessary to meeting the red and amber LED efficiency goals established by DOE. (September 2019)

Return to Research Highlights.