The Federal Energy Management Program (FEMP) identified rainwater harvesting systems as an alternative water technology that is relevant to federal facilities, is commercially available, and may offer an opportunity to offset freshwater use. This technology review is intended to provide agencies with key information to deploy rainwater harvesting systems.

Technology Description

Harvested rainwater can provide a source of alternative water to federal facilities. Alternative waters offset the demand for fresh surface water or groundwater, and can include harvested rainwater, captured condensate from air handling units, and reclaimed wastewater. Rainwater harvesting captures, diverts, and stores rainwater from rooftops for later use. Typical uses of rainwater include landscape irrigation, wash applications, ornamental pond and fountain filling, cooling tower make-up water, and toilet and urinal flushing. With additional filtration and disinfection, harvested rainwater can also be treated to potable standards to supplement municipal potable water supplies to facilities.

System Components

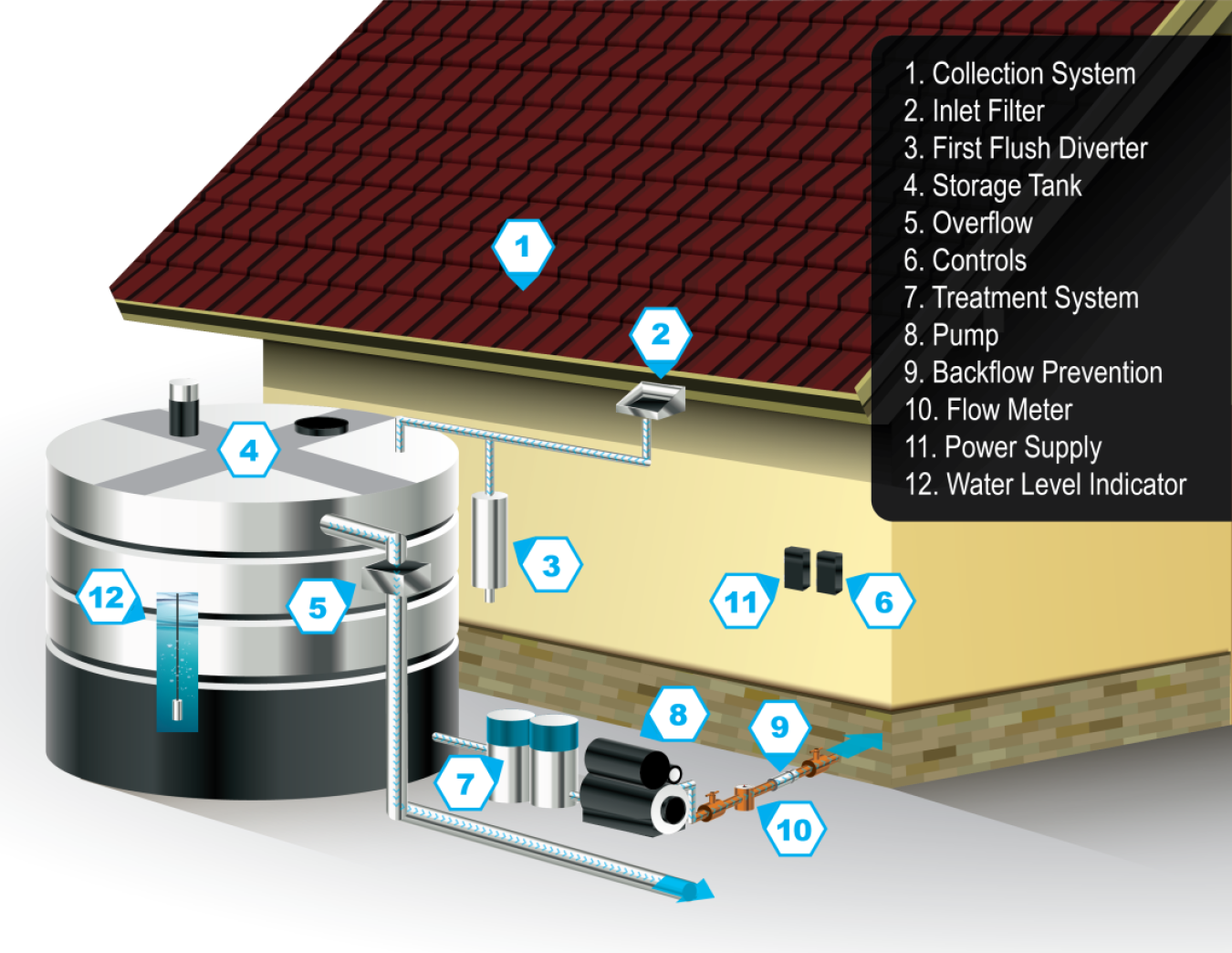

The major components of a rainwater harvesting system are displayed in Figure 1.

Figure 1. Components of a typical rainwater harvesting system

- Collection system: Roof surface and gutters to capture the rainwater and send it to the storage system

- Inlet filter: Screen filter to catch large debris

- First flush diverter: Diverter that removes debris not captured by the inlet filter from the initial stream of rainwater

- Storage tank: Storage tanks composed of food-grade polyester resin material approved by the U.S. Food and Drug Administration (FDA), which is green in color and helps to reduce bacterial growth

- Overflow: Drainage spout that allows for overflow if the storage tank gets full

- Controls: Control system that monitors water level and filtration system

- Treatment system: Filtration and disinfection system that treats the water to non-potable or potable standards

- Pump: Pump to move water through the system to where it will be used

- Backflow prevention: Backflow preventer to ensure that under negative pressure water cannot flow backwards through the system into the make-up water system

- Flow meter: Flow meter (with data logger) to measure water production

- Power supply: Systems may use either conventional power sources or, to improve off-grid capabilities, alternative sources such as stand-alone or grid-tied solar systems

- Water level indicator: Monitors the water level in the storage tank

Technology Considerations

The following are important considerations when planning for a rainwater harvesting project.

- End Use: The intended end use of the harvested rainwater will determine the type of treatment equipment that the system will need.

- Site location: Choose sites with adequate rainfall for the application. For more information, see the Rainwater Harvesting Tool.

- Applications: Choose a location that has multiple applications that can use rainwater, such as vehicle wash, landscape irrigation, and dust suppression.

- Size of catchment area (roof size): A larger roof area can capture significant amounts of precipitation, even in areas of low rainfall availability.

- Rainwater storage capacity: Areas with less frequent precipitation may require larger tanks to provide more storage capacity between water recharge. An increased tank size will increase equipment cost.

- Roof pitch and type: Roof material and pitch influence the amount of water that can be harvested. Lower-pitched roofs tend to catch more water than steeply pitched roofs. Smoother roof textures will facilitate runoff better than textured roofs.

- Water rates: Areas with higher water rates will make rainwater harvesting projects more economically viable.

- Permits: Rainwater harvesting permits may be required. Check with your local or state government. For more information, see the Rainwater Harvesting Tool.

System Sizing

Here are the basic steps to properly sizing the storage tank of a rainwater harvesting system.

- Determine how much rainwater is available for harvesting. FEMP's Rainwater Harvesting Calculator can be used to estimate the amount of monthly rainfall over a typical year that can be collected from a rooftop or other hard surfaces.

- Estimate the application’s water demand over the same period. If possible, determine the monthly demand for the application over a full year.

- Compare the amount of monthly rainfall that can be harvested to the monthly water demand over the year. Is there generally enough rainfall to supply a significant portion of the application’s demand?

- Determine an optimal storage tank size that provides enough volume to store adequate rainfall to meet the demand while not oversizing the tank.

Note: If there are large variations in rainfall throughout the year, a larger tank may be necessary to store rainwater during wet months for use during drier months. Additional treatment may be necessary to maintain water quality. In addition, it may be advantageous to compare weekly precipitation to weekly demand to get a more precise picture of the availability of rainfall to meet the water requirements of the application.

FEMP's Rainwater Harvesting Tool uses the following formula to calculate the monthly rainwater available for harvest:

Monthly Rainfall Collected (gal)

= Catchment Area (roof size)(square feet) × Monthly Rainfall (inches)

× Conversion Factor × Collection Factor

Where:

- Catchment area (roof size) is the size of the roof where rainfall will be collected

- Monthly rainfall is total amount of rainfall (in inches) for the month

- Collection factor is a factor applied to the total monthly harvesting potential to account for losses in the system. The Texas Manual on Rainwater Harvesting recommends using between 75% and 90%, depending on how efficiently the rainwater harvesting system collects rainfall

- Conversion factor is a factor of 0.62 used to convert the total amount of rain (in inches) that falls onto the roof area to total monthly gallons of harvesting potential.

Operation and Maintenance

Rainwater harvesting systems require regular operation and maintenance. Generally, the components of the system are made to last with regular upkeep, and manufacturers will often provide several years of warranty, anywhere from 15 to 30 years for storage tanks and pipework, and typically 2 to 10 years for pumps.

Table 1 lists the recommended operations and maintenance (O&M) actions for the major components. These actions should accompany actions recommended in manufacturer materials specific to the installed equipment.

Table 1. Rainwater Harvesting Components Shown in Figure 1 and Associated Maintenance Actions

| Number | Component | Description | Maintenance Actions | Suggested Frequency |

|---|---|---|---|---|

| 1 | Collection system | Roof surface and gutters to capture rainwater and send it to the storage system. | Keep clean and clear of excessive debris, especially after prolonged dry periods or after storms. Inspect roof surface and ensure water flows and drains properly as intended. | Weekly |

| 2 | Inlet filter | Screen filter to catch large debris. | Clean out filter and replace at regular manufacturer-specified intervals. | Weekly; manufacturer-specified intervals |

| 3 | First flush diverter | Diverter that removes debris not captured by the inlet filter from the initial stream of rainwater. | Keep clean and clear of excessive debris, especially after prolonged dry periods or after storms. Ensure the diverter is functioning as intended, diverting only the initial flush of water during rainfall. | Monthly and after prolonged storms |

| 4 | Storage tank | Storage tanks composed of FDA-approved, food-grade polyester resin material that is green in color, which helps to reduce bacterial growth. | Inspect tank for cracks or leakage. Infrequent blowdown may be needed to remove sediment from the bottom of the tank. If filters are regularly maintained, sediment accrual should be minimal (2 mm to 2 in. per year). | Annually |

| 5 | Overflow | Drainage spout that allows for overflow if the storage tank gets full. | Visually inspect overflow spout to ensure it is clear of debris. | Monthly |

| 6 | Controls | Control system that monitors water level and filtration system. | Ensure controls operate as intended, visually confirm response to control commands. Request manufacturer maintenance as needed to repair any controls issues. Check that wiring is in good condition. | Monthly |

| 7 | Treatment system | Filtration and disinfection system that treats the water to non-potable or potable standards. | Clean and replace filters at manufacturer-specified intervals. Ensure treatment system dosing intervals are sufficient to meet water quality requirements in the system. | Manufacturer-specified intervals |

| 8 | Pump | Pumps move water through the system and to the end use. | Check motor condition. Investigate excessive vibration, noise, or temperature. Perform pump maintenance, such as bearing lubrication, in accordance with manufacturer specifications. | Monthly; Manufacturer-specified intervals |

| 9 | Backflow prevention | Backflow preventer to ensure that water cannot flow under instances of negative pressure. | Have an approved professional test annually or at a frequency required by local regulation. | Annually |

| 10 | Flow meter | Flow meter (with data logger) to measure water production. | Ensure meter is calibrated per meter manufacturer instructions. Track water use regularly through meter readings automatically (with data logger) or manually with a log book. | Monthly |

| 11 | Power supply | Systems may use conventional power sources, or, to improve off-grid capabilities, may use alternative sources such as stand-alone or grid-tied solar systems. | Check power supply and equipment after power outages and ensure no damage to components. Follow manufacturer operation and maintenance guidelines for alternative stand-alone power supplies (e.g., solar photovoltaic panels). | As needed; Manufacturer-specified intervals |

| 12 | Water level indicator | Monitors the water level in the storage tank. | Ensure the indicator is functioning as intended. | Monthly |

| 13 (not shown in Figure 1) | Potable water connection | Make-up water supply (e.g., municipal water) to meet system needs when rainfall is not adequate to meet demand (not pictured). | Inspect potable water supply connection and backflow preventer and ensure that connections are in good condition without leaks. Comply with any regulations for testing required by local ordinances. | Annually |

Treatment for Potable Application

Harvested rainwater is typically used in non-potable applications but can meet potable standards with additional treatment. For potable systems, a licensed operator must maintain the system to ensure that it continues to produce water at a quality fit for human consumption. Additional considerations and components more specific to potable systems are shown in Table 2.

Table 2. Additional O&M Considerations Specific to a Potable Rainwater Harvesting System

| Component | Description | Maintenance Actions | Suggested Frequency |

|---|---|---|---|

| Water quality | Water must be regularly tested by a licensed operator to ensure it is safe for human consumption. | Perform water quality test; check water quality for proper chemical balance. Monitor turbidity level. Test pH, temperature, and disinfectant residual. | Daily |

| Filter cartridges/membranes | Water is pumped through the filters/membranes that must remove at least 99% of particles that are 3.0 microns or larger in diameter. This is sometimes achieved in stages with filters set up in series. | Replace filters as needed per manufacturer recommendation. | Manufacturer-specified intervals |

| Disinfection systems – May be a combination of ozone, chlorination, and ultraviolet (UV) radiation | Disinfection systems are capable of inactivating (or killing) viruses that might be in the water. | Ensure dosing intervals are set as needed to sufficiently disinfect the amount of water processed through the system. Ongoing monitoring is essential to achieving this requirement. Ensure chemical supply and injection system levels are adequate. Replace equipment such as ultraviolet (UV) lights at the end of their life. A UV lamp typically lasts about 1 year, and its effectiveness begins to diminish as it ages. Ceramic and titanium plates, fuses, and filters in ozone generators may need to be cleaned or replaced. Consult manufacturer specifications for frequency of maintenance. | Daily; Manufacturer-specified intervals |

Related Links

- Rainwater Harvesting Calculator: Tool that estimates the amount of monthly rainfall that can be harvested from rooftops or other hard surfaces

- Rainwater Harvesting Tool: Mapping tool showing state-by-state regulations and range of available rainwater for harvesting across the U.S. for both year-round application and for landscape irrigation.

More Opportunities

Read about these additional water-efficient technology opportunities.