Overview of the Fleet Management Framework

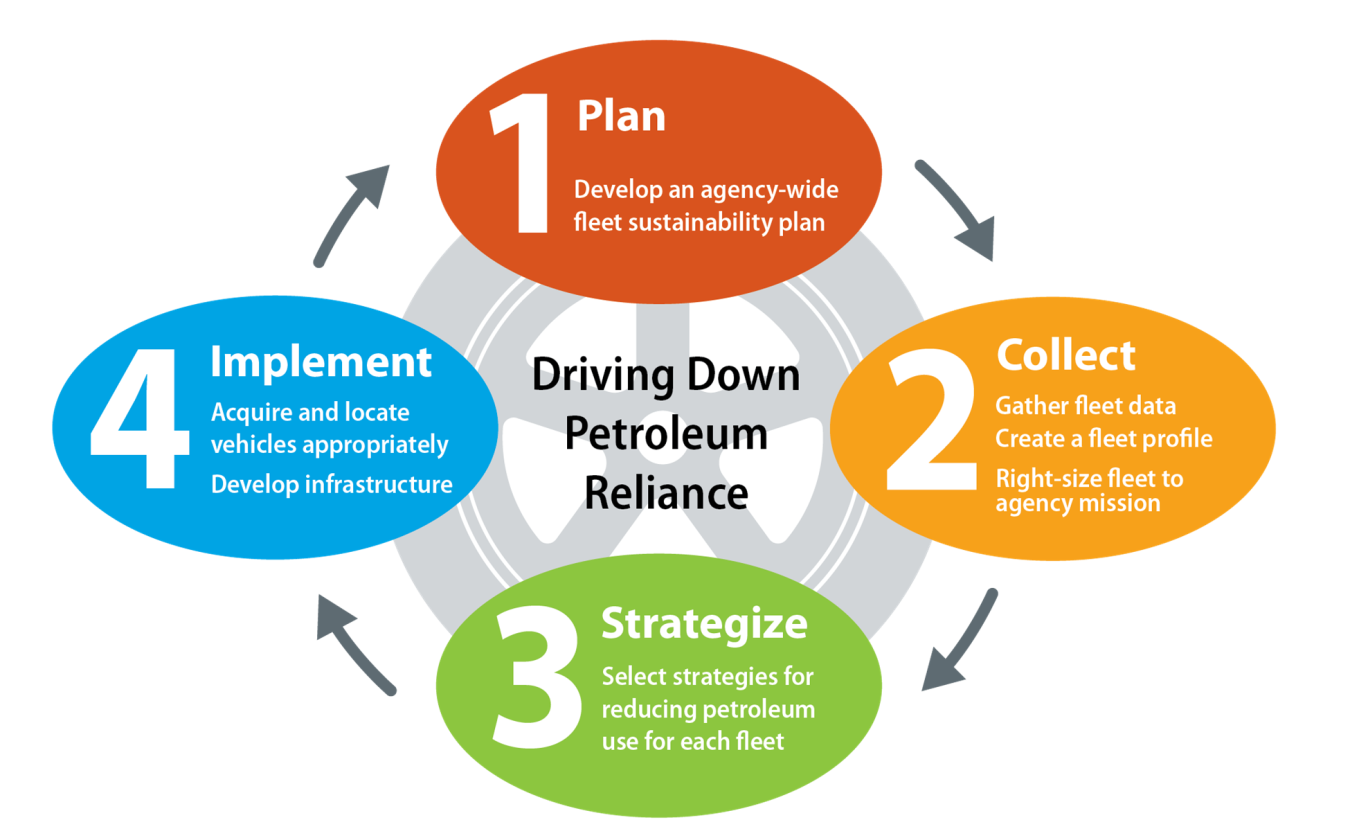

The Federal Energy Management Program (FEMP) recommends a fleet management framework for fleet managers to develop, implement, and execute an overall fleet-specific petroleum reduction strategy while complying with all Federal goals and mandates and optimizing fleet management. The figure below outlines the Federal fleet management framework.

Fleet strategic planning and implementation process framework for agencies

The fleet management framework is arranged into the following four components:

- Plan: Establish an overall agency integrated multiyear strategic plan to reduce petroleum consumption. The output of the planning phase includes the EISA Section 142 Fleet Plan.

- Collect: Compile and manage accurate and comprehensive asset-level vehicle data and vehicle telematic data to enable agencies to optimize fleet decision making, establish a baseline fleet profile, and use that profile to right-size the fleet and vehicles to the agency mission. These data will enable agencies to identify the most promising fleet strategies to reduce petroleum consumption in the third framework step, strategize.

- Strategize: Evaluate strategies at each fleet location to reduce petroleum consumption, including right-sizing fleets and vehicles to missions, reducing vehicle miles travelled (VMT) and idling, increasing fleet fuel efficiency, and increasing use of electricity (through deployment of electric vehicles [EVs] and related charging infrastructure) and other alternative fuels (including biodiesel blends).

- Implement: Acquire and locate vehicles to support petroleum reduction strategies, ensure fleet and individual vehicles are right-sized to the agency mission, support alternative fuel infrastructure development where possible, monitor and report performance in meeting petroleum reduction targets, identify deficiencies, and refine strategy as needed. Both vehicle location and duty cycle are important factors for implementing many petroleum reduction strategies, including identifying candidate vehicles for replacement with EVs and deploying dual-fueled vehicles in locations where alternative fuel infrastructure is available.

Fleet Management Framework Step 1: Plan

The first step in developing a framework for creating and implementing a fleet-specific petroleum reduction strategy for Federal fleet managers is developing an agency-specific fleet plan. This process typically includes four steps and components detailed below.

The first step in crafting a fleet plan is to define the overarching fleet management vision and goals. At the minimum, the fleet must comply with all Federal fleet management statutes, with meeting or exceeding the EISA Section 142 petroleum reduction goal as the priority for fleet performance. Other goals may include reducing fleet costs, improving fleet fuel efficiency, transforming existing the fleet composition to new vehicle types or capabilities, investing in agency fleet or infrastructure, or a combination of any of these.

After setting an overarching fleet management vision and goals, the agency should establish quantifiable annual targets for fleet petroleum reduction, alternative fuel use increases, AFV and low-GHG emitting vehicle acquisition, renewable fuel infrastructure development, as well as other targets that may be required of or important to the agency. The agency can then use these targets to evaluate whether petroleum reduction strategies both achieve the overall fleet management strategy and comply with statutory mandates.

In order to meet mission-critical needs and comply with all Federal goals and mandates, an agency can reduce petroleum use through the appropriate combination of the four core principles of fleet management:

- Right-sizing the fleet to agency mission by implementing a VAM study

- Minimizing VMT

- Increasing fleet efficiency by replacing inefficient vehicles with more fuel-efficient vehicles, maintaining vehicles, driving more efficiently, and avoiding excessive idling

- Optimizing cost-effective alternative fuel use, including maximizing utilization of existing alternative fuel infrastructure, installing alternative fuel infrastructure where practical (including EV charging stations), and aligning deployment of AFVs with fueling infrastructure.

Agency fleet managers should evaluate petroleum reduction strategies and tactics for each fleet location based on an evaluation of site-specific characteristics, including availability of alternative fuel, fleet size, and fleet vehicle composition.

Each Federal agency subject to the EISA Section 142 fleet planning requirements must develop a written plan, including implementation dates, to meet the required petroleum reduction and alternative fuel increase levels, and other relevant Federal fleet requirements. The agency plan will list the planned petroleum reduction strategies and tactics for each fleet location and project estimated reductions in petroleum consumption and increases in alternative fuel consumption to be achieved by each specific measure. Detailed information to support the fleet planning process is available at EISA Section 142 Fleet Planning, FEMP Resources and Best Practices section.

Collecting and managing high-quality data are critical elements to effective fleet management and are necessary prerequisites to developing strategies to comply with Federal fleet requirements. The importance of collecting and managing comprehensive and accurate fleet data cannot be overstated. Top-down support for data collection and management is vital to communicate the importance of data quality through all levels of an organization.

Each Federal agency is responsible for collecting and reporting asset-level data (ALD) on its vehicle fleet. As summarized on Reporting Requirements, GSA FMR Federal Management Information System section and detailed in GSA Bulletin B-15, each Federal agency must have a fleet management information system (FMIS) that:

- Identifies and collects accurate inventory, cost, and use data

- Provides the information necessary to satisfy both internal and external reporting requirements

- Collects all costs incurred in the operation, maintenance, acquisition, and disposition of motor vehicles used for official purposes

- Is capable of providing the data required for external reporting, such as FAST.

Agencies must ensure their FMIS can support the collection and management of data at the asset level and support internal and external reporting requirements. This includes feeding relevant ALD to each of the three primary Federal fleet data management systems—GSAFleet.gov, FAST, and FleetDASH. An overview of each of these systems and the relevant ALD in the FMIS are provided in the sections below.

Section 102-34.340 of the GSA FMR and 40 U.S.C. §§ 17502 and 17503 require agencies to implement a comprehensive FMIS. An FMIS serves as a centralized system to identify, collect, and analyze ALD and enables agencies to report all costs incurred for the operation, maintenance, acquisition, and disposal of its vehicles.

Agencies should ensure all ALD collected through the agency FMIS is accurate and complete. Agencies that do not have an existing, compliant agency FMIS tool should use tools developed by GSA. GSA’s Office of Governmentwide Policy offers guidance and suggestions for developing and implementing an FMIS in FMR Bulletin B-2023-55. Many agencies have employed such a system that manages some combination of their agency owned, commercially leased, and GSA leased vehicles.

Agencies must register any motor vehicles owned or leased by Federal agencies that display U.S. Government license plates within GSAFleet.gov per GSA's FMR § 102-34.120. GSAFleet.gov includes the Vehicle Registration Service, which replaced the Federal Motor Vehicle Registration System (FMVRS) in 2022. Federal fleets use GSAFleet.gov to enter, query, and update vehicle and license plate information for their vehicles. Each agency should ensure its capability to provide and update GSAFleet.gov data on a regular basis from its FMIS. Vehicles leased through GSA Fleet are automatically registered in GSAFleet.gov.

Agency fleet managers use GSAFleet.gov to ensure that requested license plates are appropriately managed and assigned to a government vehicle for official use. It is the responsibility of each fleet manager to update and maintain agency and license plate records in GSAFleet.gov, including:

- Managing tag status, including acknowledging receipt of all tags, in GSAFleet.gov (within 30 days after shipment from the manufacturer), tags attached to vehicles, tags lost or stolen (in accordance with GSA’s FMR § 102-34.135), or tags returned to the manufacturer for destruction.

- Properly associating and disassociating tags with VINs as needed

- Verifying accuracy of vehicle information

- Entering and updating contact information for each vehicle.

Federal agencies are required to collect and report accurate fuel consumption, mileage, cost, inventory, and acquisition, and mileage data into FAST for each fiscal year. Entering the information into the FAST reporting tool allows the Department of Energy (DOE) to determine whether the fleet has complied with a variety of sustainability regulatory obligations, including:

- EISA Section 142 petroleum reduction requirements

- EISA Section 142 alternative fuel use increase requirements

- EPAct 1992 AFV acquisition requirements

- Section 701 of EPAct 2005 requirements regarding alternative fuel use in dual-fueled vehicles.

Fleet data reporting requirements in FAST are summarized in the table below.

Data Requirement Federal Fleet Requirement Due Date Actual fuel cost and consumption by fuel type EISA Section 142: Evaluate compliance with petroleum reduction and alternative fuel use increase requirements

EPAct 2005 Section 701: Evaluate compliance with alternative fuel use in dual-fueled vehicles

OMB Circular A-11: Development of AFBS

Mid-December each year Vehicle inventory, acquisition, and disposal data EPAct 1992: Evaluate compliance with AFV acquisition requirements

EISA Section 141: Report on compliance with acquisition of low GHG-emitting vehicles

OMB Circular A-11: Development of AFBS

Mid-December each year Vehicle cost and mileage data by vehicle type OMB Circular A-11: Development of AFBS Mid-December each year Federal fleet fueling centers

EVSE inventory

EISA Section 246: Federal fleet fueling center throughput and renewable fuel pump data; evaluate compliance with requirement to install renewable fuel pumps

FAST Act of 2015 (Public Law No. 114-94): Requirement to report information about EVSE supporting the motor vehicle fleet as well as any EVSE available to support workplace charging programs

Mid-December each year EPAct 2005 Section 701 waiver requests EPAct 2005 Section 701: Request waivers for individual vehicles from requirement to use alternative fuel in dual-fueled vehicles Mid-December each year Optimal fleet inventory GSA FMR § 102-34.50: Data supports the VAM process to right-size the fleet and vehicles to the agency mission. June 30 each year FleetDASH is an online tool that provides Federal fleets with the capacity to track—at the asset level and at regular intervals—agency fleet fuel consumption, vehicle usage patterns, and vehicle inventories. FleetDASH users can view national summaries or drill down through agency organization levels to view individual vehicle operational patterns and fuel transactions relative to the location of existing alternative fuel infrastructure. FleetDASH allows agency users to evaluate progress in meeting petroleum reduction, alternative fuel use increase, and other sustainability efforts and identify opportunities for improvement.

Specifically, the tool uses geographic analysis to identify "missed opportunities," or instances in which conventional fuel was used when alternative fuel was available for refueling of fleet dual-fueled vehicles. An alternative fuel is determined to be available if a station known to sell the fuel is accessible by the fleet, accepts the appropriate fueling card used by GSA-leased or agency-owned vehicles, and is within 53 miles of the station where petroleum was purchased.

FleetDASH is used to automate the process to grant waivers and calculate compliance for Section 701 of EPAct 2005, as explained in EPAct 2005 Section 701 Alternative Fuel Use, FEMP Resources and Best Practices section. FleetDASH automates these processes for vehicles with fueling transaction data captured in the tool. Data required to support FleetDASH include vehicle attribute and vehicle-level fuel use transaction data. Required vehicle attribute data include:

- Unique vehicle identifier (preferably VIN)

- Organization assignment of each vehicle

- Fuel types on which each vehicle is capable of operating

- Law enforcement designation

- Emergency response designation

- Vehicle class and other descriptive information

- Garage location and point of contact information

- Vehicle utilization metrics, such as vehicle mileage.

Required fuel-transaction data include:

- Specific vehicle fueled

- Fuel quantity purchased

- Date of fuel purchase

- Fuel type purchased

- Fueling location

After establishing accurate and comprehensive ALD in an FMIS, agencies can use that data to develop an optimal fleet profile and implement a vehicle allocation methodology (VAM) to right-size the fleet and vehicles to the agency mission. Typically, the first step in developing an optimal fleet profile begins with gathering fleet data managed in an agency’s FMIS. Once the data is collected, the agency can begin conducting a detailed fleet utilization study, which entails identifying agency mission tasks and vehicle assets assigned to those tasks and allows each agency to establish a baseline fleet profile. Agency fleet managers can then use the results of the baseline fleet profile to create a list of vehicles approved for each organization that meets the agency mission and establish policies and procedures for the allocation of fleet vehicles. Ultimately, the VAM will guide the agency’s vehicle acquisition and replacement plan to ensure the fleet is correctly sized and mission appropriate—the optimal fleet.

Fleet Management Framework Step 3: Strategize

In the second framework step, collect, agency fleet managers evaluated ALD to help identify the most promising opportunities to reduce petroleum consumption at each fleet location. Agencies can then craft the most effective petroleum reduction strategies at each fleet location by evaluating the most appropriate combination of the four core principles of petroleum reduction. These principles, detailed on FEMP Best Practices: Sustainable Fleet Principles, are summarized as:

- Principle I—Right-Size Fleets and Vehicles to Mission

- Principle II—Reduce Vehicle Miles Travelled

- Principle III—Increase Fleet Fuel Efficiency

- Principle IV—Optimize Cost-Effective Alternative Fuel Use

Fleet Management Framework Step 4: Implement

The final framework step is to implement the fleet- and location-specific petroleum reduction strategies identified in the strategize framework step, in a manner than most effectively achieves the overarching fleet management vision and annual targets for fleet petroleum reduction, alternative fuel use increase, AFV and low-GHG emitting vehicle acquisition, renewable fuel infrastructure development, as well as other targets that may be required of or important to the agency.

Implementation of petroleum reduction strategies at each fleet location includes five components, which are discussed in more detail below.

Federal fleet managers can use vehicle acquisition (as identified in the VAM) to implement the agency’s optimal petroleum reduction strategy selected for each fleet location. Acquisition plans should reflect the numbers and types of vehicles required to accomplish the fleet’s mission and ensure fleet and individual vehicles are right-sized to the agency mission. In developing vehicle acquisition plans, fleet managers should look broadly at the costs and benefits of different vehicle types, including the driving environment for which they are best suited. Agencies should acquire:

- Vehicles right-sized to the mission by employing the most fuel-efficient vehicle for the required task, such as low GHG-emitting LDVs and MDPVs

- AFVs for locations with access to alternative fuel

- Biodiesel-capable vehicles for locations with access to biodiesel blends (most diesel vehicles can operate on B20).

Vehicle acquisition supports the key strategies to achieve petroleum reduction targets as follows:

- Increasing fleet fuel efficiency. Integral to reducing petroleum use is the acquisition of higher fuel economy vehicles. Agencies should identify through the VAM process the smallest, most fuel-efficient vehicles appropriate for the vehicle’s mission, and deploy those vehicles through their vehicle acquisition cycle. In most cases, a successful implementation of this strategy can be achieved through acquisition of low GHG-emitting vehicles, which are fundamentally the most fuel-efficient vehicles in their class, and through acquisition of devices that improve vehicle fuel economy, such as idling-reduction devices and telematics. Often the most cost-effective way to achieve petroleum reduction through improved fuel efficiency is by focusing on increasing the fuel efficiency of the least-efficient vehicles.

- Implementing alternative fuel, biodiesel blend, and renewable diesel blend strategies. Success in achieving and exceeding alternative fuel use mandates depends not only on fuel availability but also on vehicles that can use the fuels.

- Implementing EV strategies. EVs are extremely fuel efficient and operate on electricity, an alternative fuel. EVs are both low GHG-emitting vehicles and AFVs.

Learn more about how fleets can develop vehicle acquisition strategies to support implementation.

Strategies to reduce VMT and increase fuel efficiency include the following implementation opportunities that should be evaluated for each fleet location:

- Deploy shuttle services where practical. Guidance for Federal agencies for providing transportation and shuttle services for Federal employees is provided in GSA FMR Bulletin B-28, Federal Employee Transportation and Shuttle Services. This bulletin establishes employee transportation policies, including shuttle policies, that "maximize the use of public transportation and sharing of Federal transportation among agencies." Operational recommendations include making agency shuttle routes available to other agencies where feasible, consolidating overlapping shuttle services, incorporating AFVs in shuttles services, and enhancing the use of public transportation by Federal employees.

- Establish vehicle pools or car-sharing programs at larger fleet locations. One way for Federal fleets to increase vehicle utilization and reduce vehicle counts (and associated costs) is to establish motor vehicle pools at larger fleet locations. Creating a vehicle pool allows a fleet location to remove underutilized vehicles while still providing access to services that meet the transportation mission need.

- Launch transportation-on-demand (TOD) services. TOD services allow users to request transportation services when needed, rather than rely on an assigned fleet vehicle or vehicle pool. This includes establishing a system to schedule and deliver the following transportation services: (1) ride-sharing by booking a specific ride from one location to another; (2) car rental from hours to a few weeks; and (3) station-based mobility that allows drivers to share a trip to the same location.

- Improve vehicle preventive maintenance programs. A comprehensive vehicle maintenance strategy can help fleet managers and drivers reduce fuel use. Regular engine tune-ups ensure that vehicles operate efficiently and can increase fuel economy. Using the manufacturer's recommended grade of motor oil in an engine can improve fuel economy by up to 2%. Properly inflated tires last longer, increase fuel economy, and are safer. Every decrease in pressure by 1 pound per square inch for 4 tires can decrease fuel economy by 0.2% (keeping tires properly inflated can improve fuel efficiency by 0.6% on average, and up to 3%).

- Purchase low-rolling-resistance tires. While new cars are generally equipped with low-rolling-resistance tires, replacement tire efficiency varies significantly. Estimates from Bridgestone indicate that a 5% reduction in rolling resistance can increase overall vehicle efficiency by 1.3–1.7%.

- Install anti-idling devices and policies where appropriate. When idling, vehicles typically burn from 0.25 to 1 gallon of fuel per hour. Unnecessary idling pollutes the air, wastes fuel, and causes excess engine wear—and reducing idle time is a simple policy to implement. Establishing anti-idling policies, such as requiring drivers to turn off engines when parked or stopped for longer than a minute, is effective at helping to reduce unnecessary vehicle idling. Ambient temperature may be considered in an idling policy (such as permitting vehicles to idle if the outside temperature is below 32 degrees Fahrenheit). Additionally, a variety of technologies are available to reduce idling. These include onboard equipment such as automatic engine stop-start controls and auxiliary power units as well as technologies to keep the cabin warm when the engine is off (coolant heaters, air heaters, and energy recovery systems).

- Use telematics to assess and improve routing, scheduling, and driving behavior. Fleets can use telematics data to identify driving inefficiencies and reduce VMT and fuel use. Telematics solutions can help fleets optimize vehicle routes and schedules or provide geofencing to alert the fleet manager when drivers are traveling outside of their assigned routes. Telematics also can alert fleet managers and drivers to driving behaviors that impact the fuel efficiency of their vehicles. Research by NLR shows that improving driving behavior can reduce vehicle fuel use 5% to up to 20% for aggressive drivers.

To ensure effective implementation of strategies to displace petroleum by using alternative fuels, fleet managers must evaluate for each fleet location the availability of existing alternative fuel infrastructure, determine where new infrastructure is required, and procure the alternative fuel. The following section provides an overview to assist in deploying E85, biodiesel blend, and electric vehicle strategies.

E85 Infrastructure

Federal agencies wishing to install E85 fueling infrastructure can either convert an existing tank system or install a new tank system. At refueling sites with more than one available gasoline or diesel tank, Federal agencies can convert one of the tank systems to E85. This typically costs much less than installing a new tank system. The conversion process includes cleaning the tank and lines, ensuring fuel lines and dispenser components are compatible with E85, and calibrating the fuel metering system. At Federal fleet refueling centers without tanks that can be converted to E85, Federal agencies must install a new E85 tank. Typically, this is the costliest alternative, involving installation of a new storage tank and associated equipment, as well as related excavation, concrete, and electrical work, if necessary. Options available include installing a new underground storage tank, a new aboveground storage tank, or an aboveground turnkey E85 refueling system.

Biodiesel and Biodiesel Blend Infrastructure

Most refueling systems designed to handle diesel fuel will handle biodiesel and biodiesel blends with no problem. B20 or lower blends minimize most issues associated with materials compatibility. At refueling sites with more than one available diesel tank, Federal agencies can convert one of the tank systems to B20. Similar to conversion of E85 refueling infrastructure, the costs for this alternative are typically much less than installing a new tank system. Conversion of existing tank systems typically only includes cleaning the tank and lines. The process for installing a new B20 refueling system is similar to the process for E85 discussed above.

Procuring E85 and Biodiesel

Federal agencies should consider procuring E85 and biodiesel and biodiesel blends either through DLA Energy or directly from ethanol or biodiesel suppliers. By consolidating requirements for DoD and other Federal agencies, DLA Energy often may be the lowest cost provider of renewable fuel.

Electric Vehicle Charging Infrastructure

All BEVs, PHEVs, and LSEVs require EVSE to operate. EVSE may be as simple as connecting the adaptor cord that comes standard with most EVs to a 120-volt outlet rated for at least 15 amps. Alternatively, a dedicated 208- or 240-volt charging station may be able to provide four times more power to an EV for a quicker charge. The primary EVSE for refueling EVs should be located at the fleet facility where the vehicle is garaged. Additional EVSE may be available locally at commercial sites or other Federal fleet locations.

Before procuring and installing EVSE, fleet managers should first determine how many and what type of charging stations to acquire. After determining EVSE needs, the next step is to prepare for the placement of EVSE at the site. The siting analysis focuses on choosing a charging station location and design, deciding on the EVSE model, evaluating power requirements, and selecting data collection needs. After completing a siting analysis, the fleet manager will be ready to procure the EVSE, develop a statement of work, and contract for installation.

GSA has a pre-negotiated, multi-award blank purchase agreement (BPA) for Level 1, Level 2 and DC fast charging stations. The contract includes products from different manufacturers and data network plans but does not include installation services. Agencies should coordinate EVSE procurement through GSA in order to realize savings through volume discount pricing.

At the end of each fiscal year, agencies can use fleet data to evaluate the effectiveness of the petroleum reduction strategies implemented at each fleet location. At minimum, fleets must evaluate their performance based on compliance with Federal fleet requirements, including petroleum reduction, alternative fuel use increases, AFV and low-GHG emitting vehicle acquisition, and renewable fuel infrastructure development. Agencies may also measure performance compared to the overarching fleet management vision and goals established in the agency fleet plan. Furthermore, fleet managers can compare actual performance at each fleet location against the projected estimated reductions in petroleum consumption and increases in alternative fuel consumption to be achieved by each specific measure in the fleet plan.

In those fleet locations and areas where performance met or exceeded targets, agencies can identify best practices and effective petroleum reduction strategies. Similarly, at fleet locations and areas that failed to meet performance targets, agencies can identify areas of weakness and opportunities for improvement.

After evaluating the effectiveness of their petroleum reduction strategies to determine successes, barriers, and opportunities for improvement, agencies should revisit their planning process for the development of future petroleum reduction strategies. What works one year for a fleet may not work the next year, as the opportunities to improve Federal fleet petroleum reduction strategies increase with each new technology and expanding infrastructure. This is the point at which the fleet management process comes full circle and the planning process begins anew.